03/03/2016

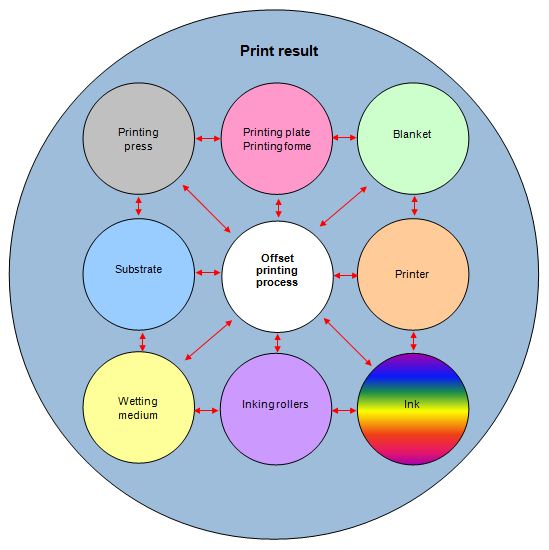

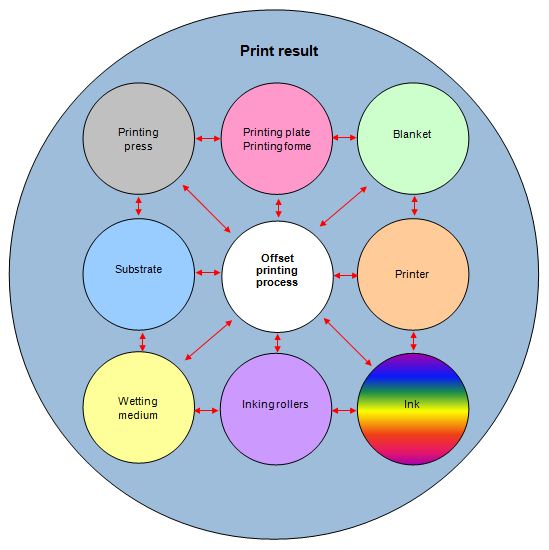

The factors influencing the print result of a printing process, especially in offset printing, are a frequent topic of lively discussion among printing technicians. The focus is usually on the printing press and the respective printing process, as this is where all the components required for printing come together. However, the print result also always reflects the interaction between the operating resources used, the materials, and the operating personnel. This series of articles discusses these influencing factors individually and describes them in detail.

The chart below shows the most important influencing factors, although the climate in the printing room—another influencing factor—is not discussed in detail due to significant regional differences.

Each of these influencing factors has a significant impact on the printing result and is directly related to the other influencing factors. The following example illustrates this:

The amount of ink set by the printer determines the amount of dampening water required. The rollers must be correctly aligned with each other to transport the ink in the inking unit. Furthermore, the ink rollers must be compatible with the ink system used. The printing plate and the blanket must also transfer the ink well to the substrate, whereby ink adhesion may also play a role depending on the substrate.

In addition to all these components of the printing process, other influencing parameters also play a role, such as the type, manufacture, or print resolution of a printing plate, the components, viscosity, resistance, and printability of a printing ink, or the maintenance of a printing press. The substrate itself also has a significant influence. It may be made of paper or film, for example, and its surface may be very smooth or rough and absorbent.

It is possible to optimize each influencing factor individually in order to achieve the desired printing result. In addition, standardization of the printing process should be aimed at in order to achieve the printing specifications more quickly and accurately. There are also corresponding ISO standards that can serve as guidelines. The ISO 12647-2 offset process standard is one example.

In the first part of this series of articles on "Factors influencing print quality in offset printing," we will take a detailed look at the printing plate and the parameters that influence it.

-2.jpg)

The graphic below shows the most important parameters influencing the printing quality and the print result.

-2.jpg)

-2.jpg)

-2.jpg)

The surface roughness of the anodized layer determines the smallest size of the halftone dots that can be reproduced on the printing plate. The finer the surface, the finer the halftone dots that can be produced.

.jpg)

.jpg)

The surface structure also determines how much moisture can be stored in the pores of the surface. This means that the finer the surface of the printing plate, the less water can be stored and the more delicate the ink-water balance becomes during the printing process.

-2.jpg)

Today, most printing plates are imaged using a CTP (computer-to-plate) system. The imaging is done with laser heads.

The CTP imagesetter must be calibrated using the printing characteristic curve that has been determined in advance on the printing press for all important types of printing substrate, and this calibration must be checked every day during printing plate production.

-2.jpg)

.jpg)

.jpg)

Depending on the printing plate, various process steps are necessary in the production of printing plates.

The process steps in printing plate production must always be checked and adhered to in accordance with the manufacturer's specifications. For example, the developer fluid must always have the correct reactivity.

In some cases, the printing plates must be baked in an oven so that they can be used with UV inks.

03/03/2016

The factors influencing the print result of a printing process, especially in offset printing, are a frequent topic of lively discussion among printing technicians. The focus is usually on the printing press and the respective printing process, as this is where all the components required for printing come together. However, the print result also always reflects the interaction between the operating resources used, the materials, and the operating personnel. This series of articles discusses these influencing factors individually and describes them in detail.

The chart below shows the most important influencing factors, although the climate in the printing room—another influencing factor—is not discussed in detail due to significant regional differences.

Each of these influencing factors has a significant impact on the printing result and is directly related to the other influencing factors. The following example illustrates this:

The amount of ink set by the printer determines the amount of dampening water required. The rollers must be correctly aligned with each other to transport the ink in the inking unit. Furthermore, the ink rollers must be compatible with the ink system used. The printing plate and the blanket must also transfer the ink well to the substrate, whereby ink adhesion may also play a role depending on the substrate.

In addition to all these components of the printing process, other influencing parameters also play a role, such as the type, manufacture, or print resolution of a printing plate, the components, viscosity, resistance, and printability of a printing ink, or the maintenance of a printing press. The substrate itself also has a significant influence. It may be made of paper or film, for example, and its surface may be very smooth or rough and absorbent.

It is possible to optimize each influencing factor individually in order to achieve the desired printing result. In addition, standardization of the printing process should be aimed at in order to achieve the printing specifications more quickly and accurately. There are also corresponding ISO standards that can serve as guidelines. The ISO 12647-2 offset process standard is one example.

In the first part of this series of articles on "Factors influencing print quality in offset printing," we will take a detailed look at the printing plate and the parameters that influence it.

The graphic below shows the most important parameters influencing the printing quality and the print result.

The surface roughness of the anodized layer determines the smallest size of the halftone dots that can be reproduced on the printing plate. The finer the surface, the finer the halftone dots that can be produced.

The surface structure also determines how much moisture can be stored in the pores of the surface. This means that the finer the surface of the printing plate, the less water can be stored and the more delicate the ink-water balance becomes during the printing process.

Today, most printing plates are imaged using a CTP (computer-to-plate) system. The imaging is done with laser heads.

The CTP imagesetter must be calibrated using the printing characteristic curve that has been determined in advance on the printing press for all important types of printing substrate, and this calibration must be checked every day during printing plate production.

Depending on the printing plate, various process steps are necessary in the production of printing plates.

The process steps in printing plate production must always be checked and adhered to in accordance with the manufacturer's specifications. For example, the developer fluid must always have the correct reactivity.

In some cases, the printing plates must be baked in an oven so that they can be used with UV inks.