Printing processes in label printing have developed continuously over many years. After many years as the leading printing process, letterpress printing was first supplemented by offset printing and then by flexographic printing.

The advantages throughout the entire production process have made flexographic and offset printing the standard in our industry. Both processes have their advantages and disadvantages and are used differently depending on the requirements.

The various printing processes place different demands on printing presses. The mechanics, control systems, and design of printing presses must meet these demands. However, the requirement for maximum print quality, reproducibility, and cost-effectiveness remains the same for all printing processes.

Gallus consistently gears its developments toward these requirements, ensuring success and reliability for the single-chain printer.

Its ease of use and high process reliability make flexographic printing the most widely used printing process in narrow web label printing. Modern flexographic printing meets high quality requirements and is characterized by excellent cost-effectiveness.

Gallus printing presses reduce waste and makeready times and offer unmatched flexibility and quality in flexo and flexo combination printing.

With more than 15 years of experience, Gallus is one of the pioneers in narrow web offset printing. Offset printing is primarily used where the highest quality standards are required in terms of screen printing and color fidelity. In combination with screen printing, hot foil stamping, or cold foil printing, breathtaking effects can be achieved.

Inexpensive printing plates and the high degree of standardization in offset printing also make this process attractive for the production of simpler labels at attractive prices.

Gallus offset solutions are characterized by the use of state-of-the-art technologies, maximum process reliability and dependability, and unmatched productivity.

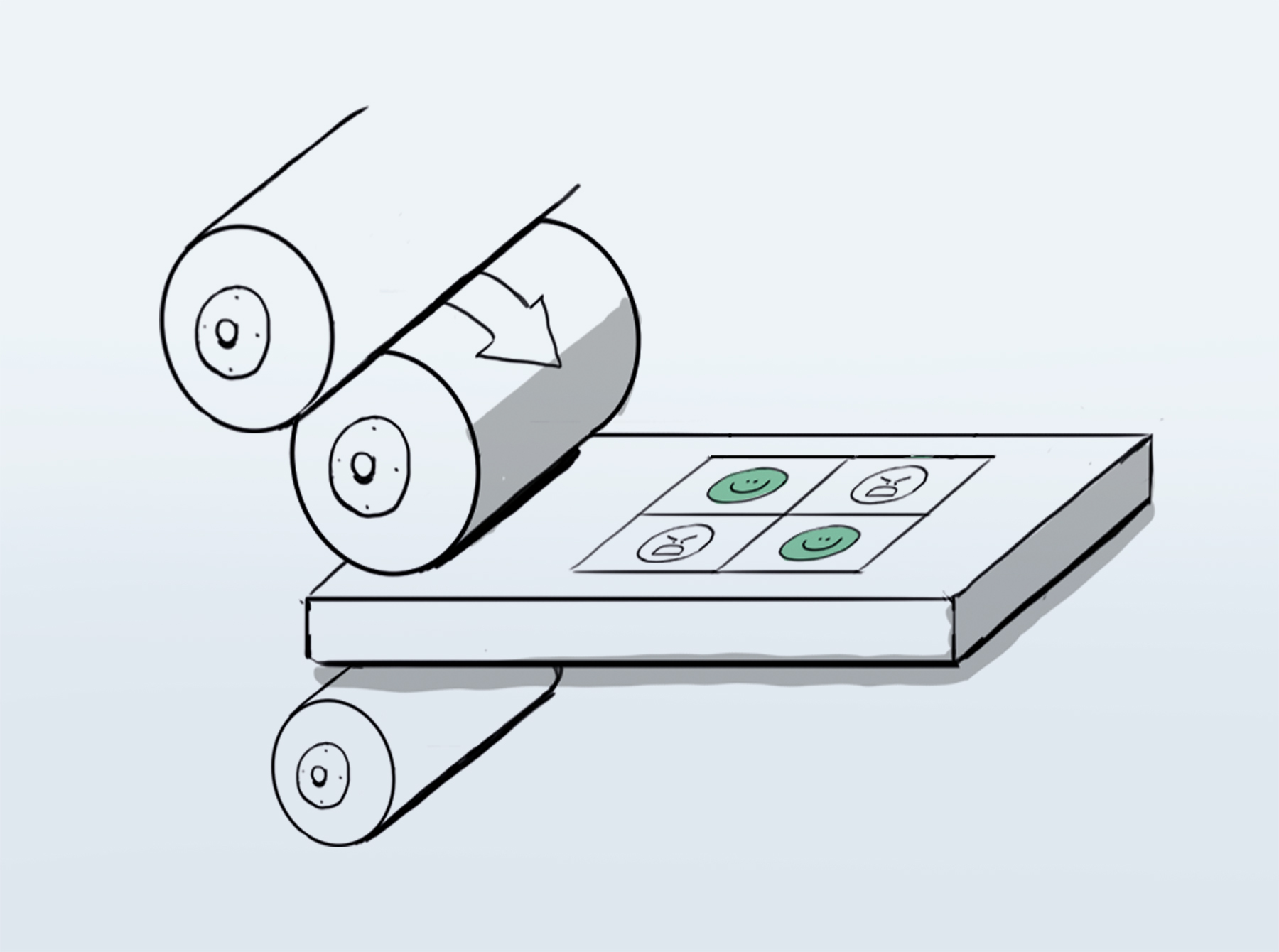

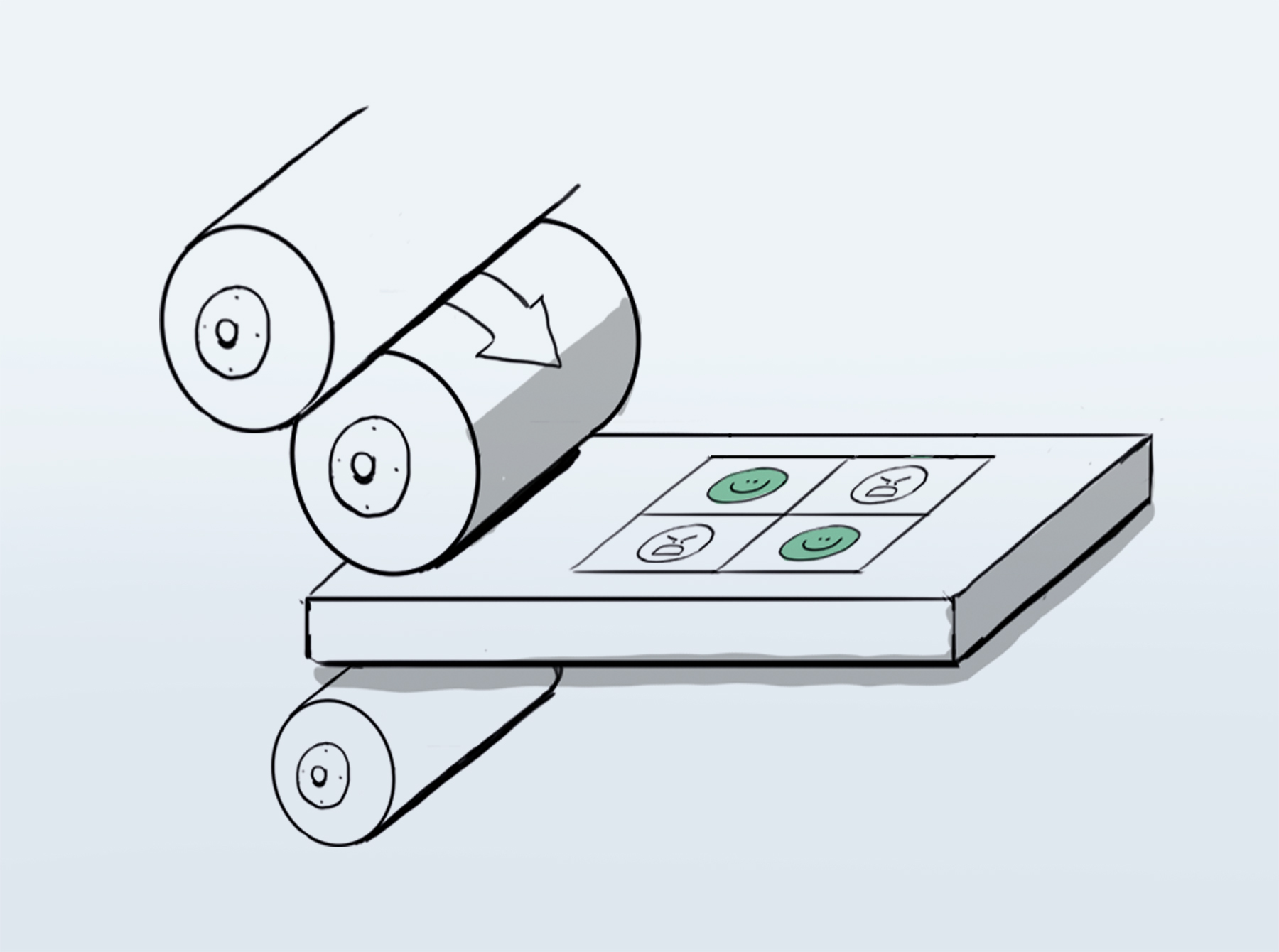

In collaboration with its partner Heidelberger Druckmaschinen AG (Heidelberg), Gallus offers a drop-on-demand (DoD) inkjet process for digital printing with a native resolution of 1200 dpi and a printing speed of up to 70 m/min in seven-color mode plus optional white.

The digital DoD inkjet process is therefore an ideal addition to high-quality applications in flexographic, offset, and screen printing, and is particularly suitable for short runs, versioning, and customization of lightly finished labels.

The digital printing system is also suitable for new applications such as smart labels, security printing, and traceable labels.

The rotary screen printing units are integrated modules in Gallus printing presses and, as such, are optimally taken into account in all stages of machine development.

Coordinated printing systems with screen printing, letterpress printing, flexographic printing, offset printing, and hot foil stamping, combined with various processing functions, guarantee reliable, economical label production.

Thanks to its integration into Gallus printing presses, the Gallus rotary screen printing system achieves the shortest possible setup times and maximum print quality.