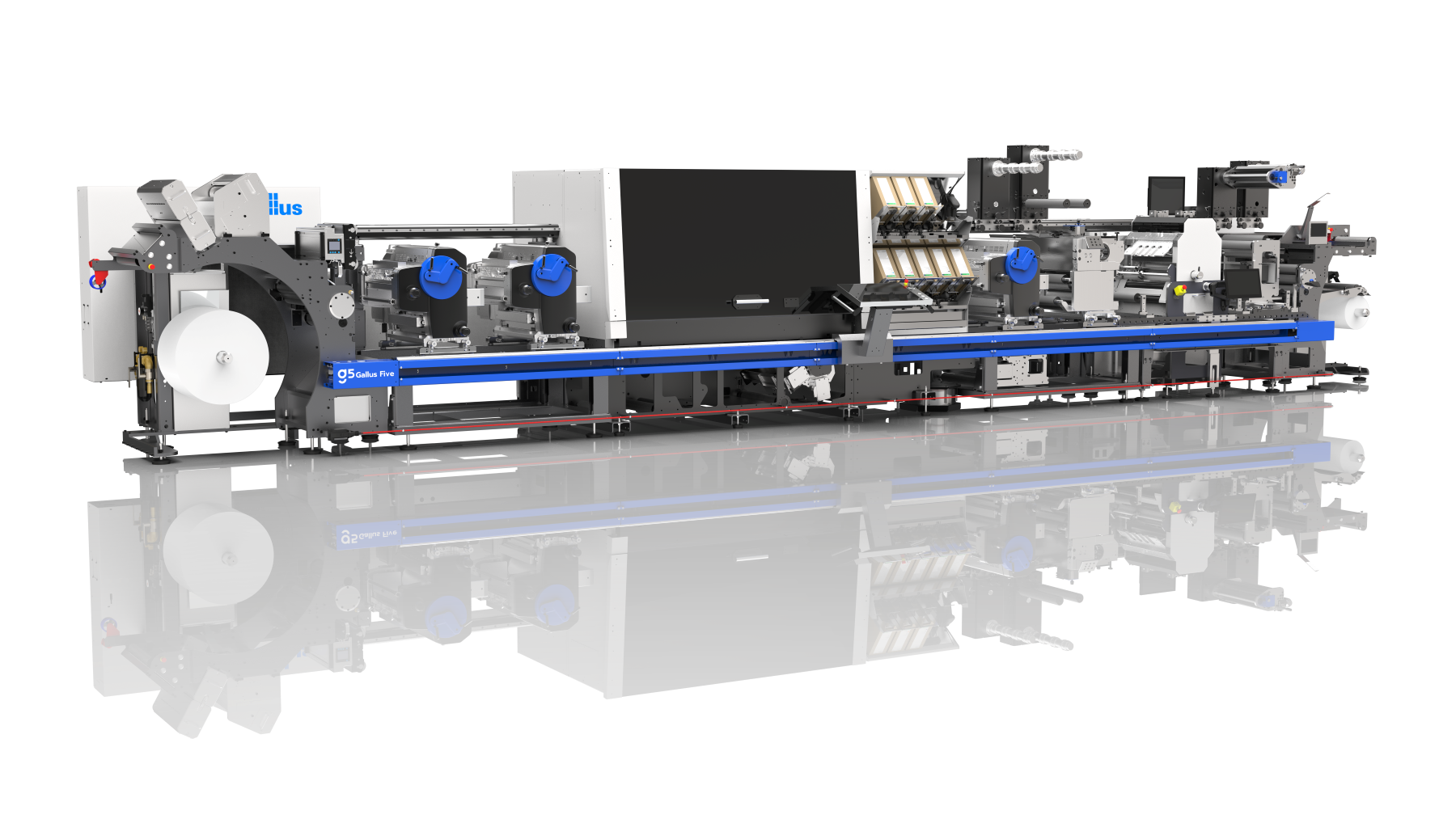

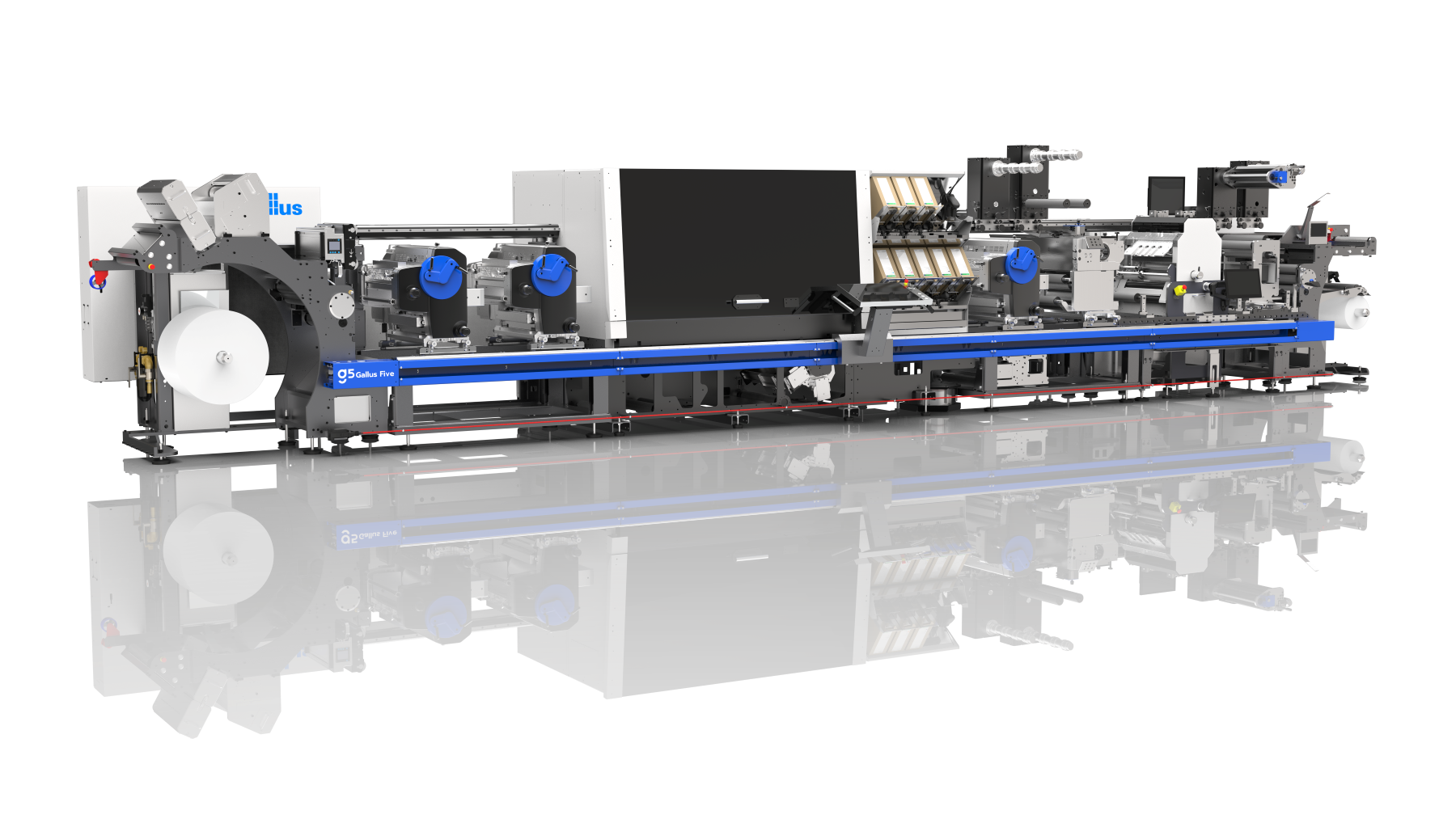

Experience the next generation of label printing with the Gallus Five, which stands out thanks to its performance, flexibility, and innovative strength. With a printing speed of up to 100 m/min, it enables fast turnaround times and high production volumes—without compromising on print quality.

Specially designed for medium to high print runs, the Gallus Five shifts the economic break-even point for hybrid label production from 5,000 to an impressive 10,000 running meters. This means maximum productivity with lower unit costs and a significantly improved TCO (total cost of ownership).

Thanks to its modular architecture and seamless integration into the to Compose system, the Gallus Five is optimally designed to adapt flexibly to changing production requirements. Based on the proven Gallus Labelmaster platform, it can be configured with a print width of either 340 mm or 430 mm.

The future-proof, modular design allows for easy configuration and subsequent expansion with printing, finishing, and die-cutting modules. This makes the Gallus Five the perfect solution for companies that want to stay one step ahead in a dynamic market environment.

In addition to all the advantages of the System to Compose, such as physical modularity, sophisticated workflow solutions such as operability via HEIDELBERG Prinect, and a modular service offering, the Gallus Five impresses with innovative components that further increase efficiency and performance. These include the newly developed Heidelberg Saphira UV05 ink set, the high-performance SDC Pro semi-rotary die cutter for a print width of 430 mm, and the new, energy-efficient LED drying unit.

All components are perfectly matched to ensure maximum uptime and efficiency.

The new Heidelberg Saphira UV05 ink, developed in collaboration between HEIDELBERG and Gallus, complies with current regulations for safe inks. It is therefore particularly suitable for demanding and sensitive applications, such as those in the health, beauty, and cosmetics sectors.

In addition, the ink set (6C + white) offers unparalleled color brilliance and reduced ink consumption thanks to its high color pigmentation, even at full production speed. The Heidelberg Saphira UV05 also covers the 32 most common PANTONE® spot colors in packaging printing with minimal ∆E.

The new high-performance SDC Pro semi-rotary die cutter is designed for maximum efficiency. It enables die cutting at a width of 430 mm and speeds of up to 100 m/min. The innovative design guarantees quick die plate changes without having to replace the die cylinder, which significantly reduces setup times.

The Gallus Five is equipped with advanced LED pinning and curing technology. The integration of GEW LeoLED reduces power consumption by up to 50%, resulting in significant savings in energy costs. In addition, customers benefit from the longevity of LED technology, which not only increases efficiency but also enables sustainable and resource-saving printing operations.

From significant time savings thanks to simple operation and automated functions, to an impressive printing speed of up to 100 m/min, to significant energy savings thanks to innovative LED drying. The Gallus Five impresses from the very first print with outstanding Gallus quality and makes hybrid label printing faster, more efficient, and more economical.

Whether you produce labels for healthcare and beauty products, household goods, technical products, or pharmaceutical and OTC products, the Gallus Five is up to the challenge. It is the perfect solution for large print runs that require a high level of finishing, delivering impressive results with every print run.

| 340 | 430 | |

| Machine speed, mechanical, max. | 100 m/min. 328 ft/min. | 100 m/min. 328 ft/min. |

| Maximum print width | 340 mm 1:39 p.m. | 430 mm 16.92 in |

| Productivity | 2040 m²/h (21,948 ft²/h) | 2580 m²/h (27,771 ft²/h) |

| Maximum track width | 345 mm 13:58 in | 445 mm 17.5" in |

| Splice inspection | automatically | automatically |

| Teknek rail cleaning | on both sides | on both sides |

| Corona | Front side or both sides | Front side or both sides |

| Antistatic system | Passive or active | Passive or active |

| CO2-compensated | Yes | Yes |

| 13.4 / 1.7 inches | |

| Printing method | UV Piezo DoD - Inkjet (Fuji Dimatix) |

| Print resolution | 1200 x 1200 dpi native print resolution with 2 pL drop size, optical resolution 2400 x 2400 dpi |

| Ink | Heidelberg Saphira UV05 |

| Colors | CMYK (cyan, magenta, yellow, black), orange, violet |

| White (optional) | 85% opacity |

| Pinning | Single-color pinning / UV-LED air-cooled |

| UV curing | LED curing (GEW LeoLED) |

| Automatic cleaning system | contactless; additional ultrasonic cleaning system for intensive cleaning |

| Vision System | Automatic visualization of pressure on the HMI |

| Digital Print Control | Automatic nozzle error detection and compensation / Density unevenness detection and compensation |

| Substrate qualification | automatic inline qualification (100% system-supported) |

| Automatic Digital Register | Yes |

| Industrial Variable Data Printing (iVDP) | Industrial Variable Data (iVDP) included, Full FDP optional |

| Insetting | Optional |

| 340 / 430mm | |

| Installation | On-site or cloud-based |

| Digital Front End (DFE) | Server/client architecture |

| Server | Hardware or virtualized |

| Ink consumption | Preliminary calculation |

| 13.4 / 1.7 inches | |

| Monofilm | yes |

| Paper | yes |

| Composite materials | yes |

| 13.4 / 1.7 inches | |

| Suspense | 380-415 V / 50 Hz |

| Power connection | Depending on the machine configuration |

| Compressed air | 6 bar, oil- and water-free |

| Exhaust air | Depending on the machine configuration |

| Conformity | CE, GS (UL upon request) |

| Network connections | Secomea for remote maintenance, Prinect & GEW support |

| Cooling system | Air cooling for UV lamps and pinning |

| Water | Water for UV LED lamp heads, electronics, and web (cooling roller) |

| Room temperature | 20–25 °C (68–77 °F) |

| Humidity (relative) | 40-60% |

| Air pressure (location) | 700 - 1060 mbar (10.5 - 15.37 PSI) |

| 340 / 430mm | |

| dimension | Depending on the machine configuration |

| 340 / 430mm | |

| Supply | 1500 mm (59 in) |

| Issue | 1500 mm (59 in) |

| Front | 1500 mm (59 in) |

| Rear | 1000 mm (39 in) |

| Flatness | ± 1 cm over a length of 10 m |

| Load capacity | 1600 kg/m² (2,2757 psi) |

| All technical data, descriptions, and illustrations are subject to change and are not binding. |

In an industry where precision, efficiency, and innovation determine success, in-depth expertise is the most important asset. The Gallus Print Academy training system has been specially developed to help printing companies make the transition from conventional printing processes to digital and hybrid printing.

In keeping with the principle that "modularity is key," the training program is also modular in structure. This allows customers to put together their own individual program and receive training from our printing experts directly at their production site.