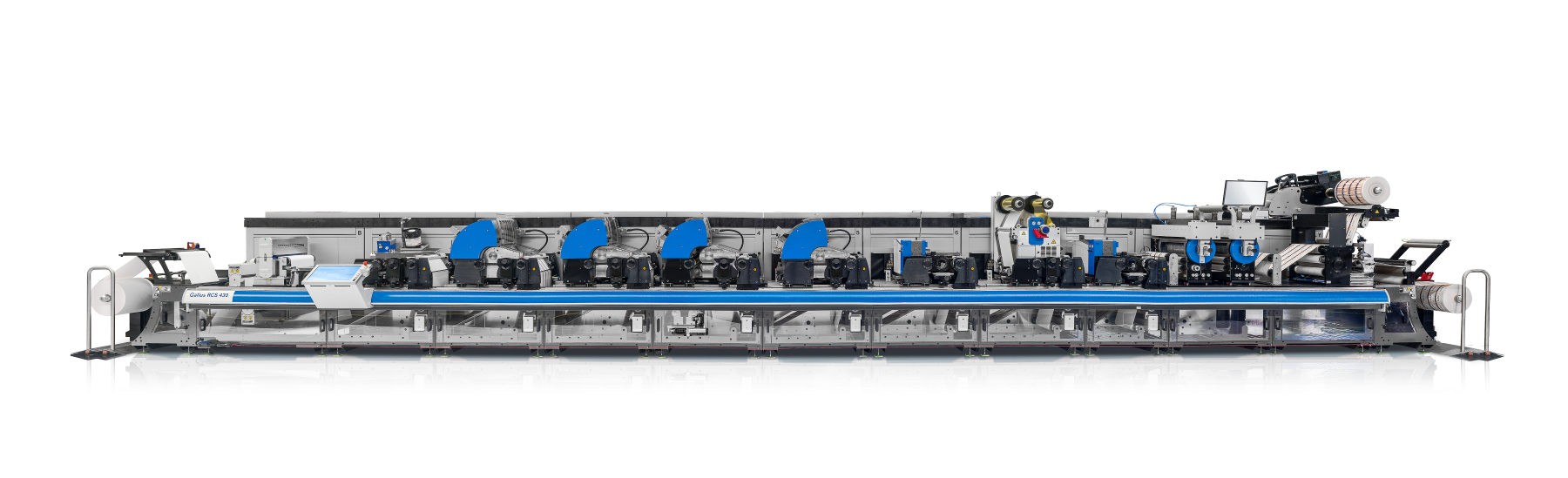

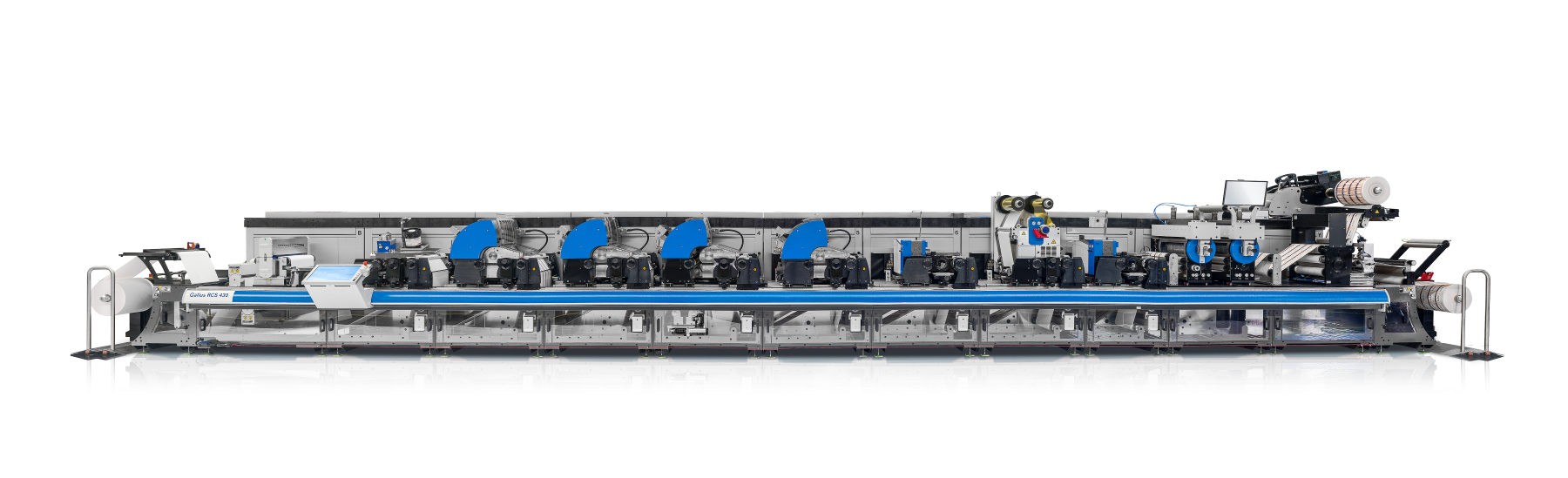

The Gallus RCS 430/570 stands out thanks to its high degree of automation and maximum flexibility in the choice of printing processes. The successful machine system impresses across the board with its unique modular design. Label printers around the world trust in the high productivity of Gallus RCS machine systems, setting quality standards in label printing. With the RCS 430, Gallus has set a technical milestone with its modern UV offset printing presses.

As a modular, in-line printing press with direct drive, the Gallus RCS 430/570 can be configured and expanded as required. Individual printing processes can be exchanged without web separation. Thanks to the high degree of automation in all modules, the machine impresses with minimal waste and greatly reduced changeover times. The Gallus RCS 430/570 also features dynamic print delivery, web tension, longitudinal and cross register presetting, and automatic washing devices.

from the working memory for repeat orders

via the Internet

with all resources for maximum eco-efficiency

UV offset (only available for Gallus RCS 430), UV flexo and rotary screen printing, solvent gravure printing, hot foil stamping and cold foil printing – individually or in combination

Coating, lamination, or laminating

The Gallus RCS 430/570 supports six printing processes, thereby redefining the future of label printing. Offset printing (only available for Gallus RCS 430), flexographic printing, screen printing, and hot foil stamping can also be easily positioned anywhere along the machine in just a few minutes—without separating the web. Secondary processes such as cold foil embossing, laminating or reverse printing can also be quickly and easily positioned anywhere on the secondary rail system.

The Gallus RCS 430/570 offers every label printer unique application and process flexibility. This printing press easily handles every substrate – from extremely thin mono films with a thickness of just a few micrometers to tube laminates with a thickness of up to 450 micrometers.

The consistent platform concept, modular design, and high degree of automation guarantee economical and efficient production with maximum print quality. Machine settings from the working memory for repeat jobs can be retrieved at any time via the job data memory.

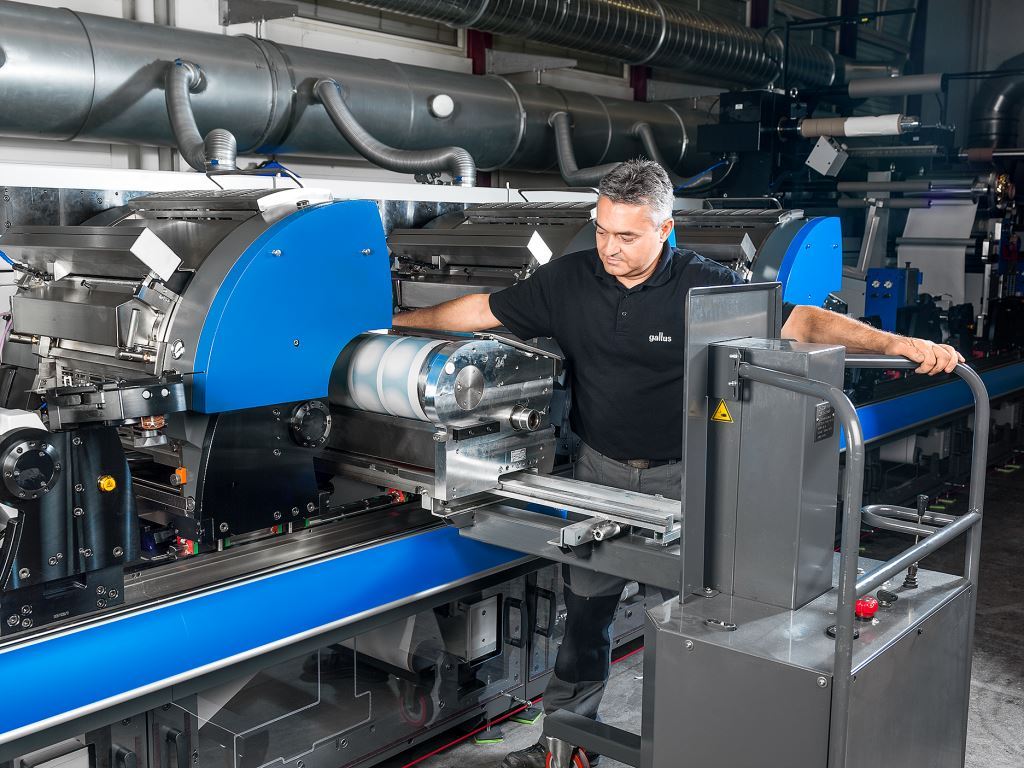

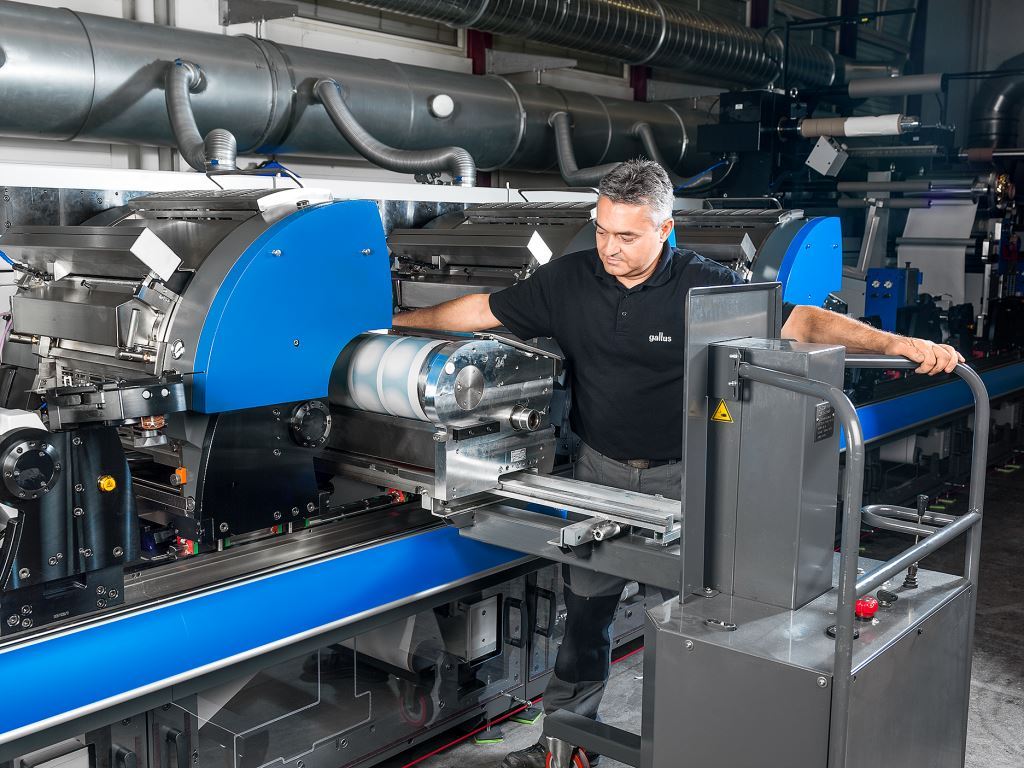

The new generation of Gallus machine systems are equipped with the latest control technology and open up synergy potential for label printers in the use of various Gallus machine systems – in line with a uniform technology platform and operating concept. Further advantages include intuitive user guidance via a modern touchscreen panel. Feedback and experience from Gallus RCS users have led to numerous insights that have resulted in various technological adjustments to the hardware, including improvements in web transport and increased register accuracy. The ink units optimized in the offset printing unit also offer even better ink stability in the new RCS 430.

With Flying Imprint for flexographic printing, it is possible to change text and motifs without stopping the machine. Thanks to maximum, end-to-end automation, the Gallus RCS 430/570 impresses with very short job changeover and makeready times and minimal waste. The format flexibility of the Gallus RCS 430/570 also makes the press completely flexible in terms of printing processes, substrates and job structure.

The ink and dampening units on the Gallus RCS 340 are individually driven. This means that the required ink/water balance is achieved even before the actual printing process begins. The start-up sequence allows the offset printing unit and the format cassette to rotate at setup speed, with the web moving at only 1 m/min. This means that production quality is achieved very quickly with minimal start-up waste. In conjunction with the ink zone presetting, the Gallus RCS 430 sets a new benchmark in offset printing for label printers in terms of operator efficiency.

With a Gallus RCS 430, label printers achieve the best possible print results while maintaining optimum performance and cost-effectiveness. The robust design, state-of-the-art servo drive technology and an intelligent user interface guarantee optimum print quality. Thanks to its high degree of automation, the Gallus RCS 430 achieves results in web printing that are comparable in quality to those of sheetfed offset printing.

With a Gallus RCS 430, the label printer achieves the best possible print quality. The inking and dampening unit of the Gallus RCS 430 is designed with 21 rollers – for consistently high, reproducible print quality, very short makeready times, and reduced waste. As in modern sheetfed offset presses, the dampening water is applied via a separate dampening roller, while three ink rollers transfer the ink to the plate cylinder. A bridge roller separates or connects the dampening unit to the inking unit. This can be adjusted for quick inking or washing and for printing without a dampening unit – e.g. for full-surface coating. Separating the dampening and inking units is also recommended when working with metallic inks. The Gallus RCS 430 remains at the highest possible level in terms of performance and economy. The robust design, state-of-the-art servo drive technology, and an intelligent user interface guarantee optimum print quality. Thanks to its high degree of automation, the Gallus RCS 430 achieves results in web printing that are comparable in quality to those of sheetfed offset printing.

Equipped with the latest configurable servo direct drives, the Gallus RCS 430 enables continuous production. The inking unit maintains a constant temperature and the ink quantity is permanently adjusted to the operating speed. In addition, the dampening roller and ink transfer roller are equipped with direct drives.

Adjustments to the motorized color printing units can be made quickly and easily. This guarantees consistent and accurate reproduction of print results. Using an independent drive controller for the ducture drive, the ink/water profiles of each individual offset printing unit on the Gallus RCS 430 can be individually adjusted, saved and later easily retrieved from the job data memory.

| Gallus RCS 430 | Gallus RCS 570 | |||

| Machine speed, mechanical, max. | 160 m/min. | 160 m/min. | 160 m/min. | 525 ft/min. |

| Maximum track width | 435 mm | 17 1/8 | 575 mm | 22.6 inches |

| Track width min. | 210 mm | 8 1/4 | 300 mm | 11.8 inches |

| Maximum printing and processing width | 430 mm | 17 | 570 mm | 22.4 |

| Gallus RCS 430 | Gallus RCS 570 | |||

| Format range | 304.8 - 635.0 mm | 12" - 25" | 355.6 - 635.0 mm | 14" - 25" |

| Standard format length gradation | 3,175 mm | 1/8 | 3,175 mm | 1/8 |

| Format length gradation optional | stepless | stepless | stepless | stepless |

| Maximum number of printing operations | 14 | 14 | ||

| Gallus RCS 430 | Gallus RCS 570 | ||

| Format range | 330.2–635.0 mm | 13" - 25" | |

| Standard format length gradation | 25.4 mm | 1" | |

| Format length gradation Optional | 3,175 mm | 1/8" | |

| Number of offset printing units max. | 8 | ||

| Number of color zones | 17 | ||

| Number of order rollers | 4 | ||

| Number of wet application rollers | 1 | ||

| Number of paint application rollers | 3 | ||

| Number of color friction rollers | 4 |

| Gallus RCS 430 | Gallus RCS 570 | |

| UV | yes | yes |

| Hot air | upon request | upon request |

| Gallus RCS 430 | Gallus RCS 570 | ||

| Format range | 304.8–635.0 mm | 12" - 25" | upon request |

| Standard format length gradation | 3,175 mm | 1/8" | upon request |

| Format length gradation Optional * | stepless | stepless | upon request |

| Maximum number of processing operations | upon request | upon request | |

| Gallus RCS 430 | Gallus RCS 570 | |

| Adhesive composites | yes | yes |

| Paper | yes | yes |

| Cardboard | yes | yes |

| Monofilm materials | yes | yes |

| Tube laminates | yes | yes |

| Gallus RCS 430 | Gallus RCS 570 | |

| yes | yes |

All technical specifications are approximate values. Technical data depends on machine configuration, order, web width, consumables, substrate, and other factors. We reserve the right to make technical and other changes.

* For 1-piece tool