Rising cost pressures, complex label designs, declining print runs, and just-in-time deliveries—the label market is constantly changing. This calls for efficient and economical label production. The Gallus ECS 340 is the best-selling machine system in its class—perfect for reducing costs while increasing productivity.

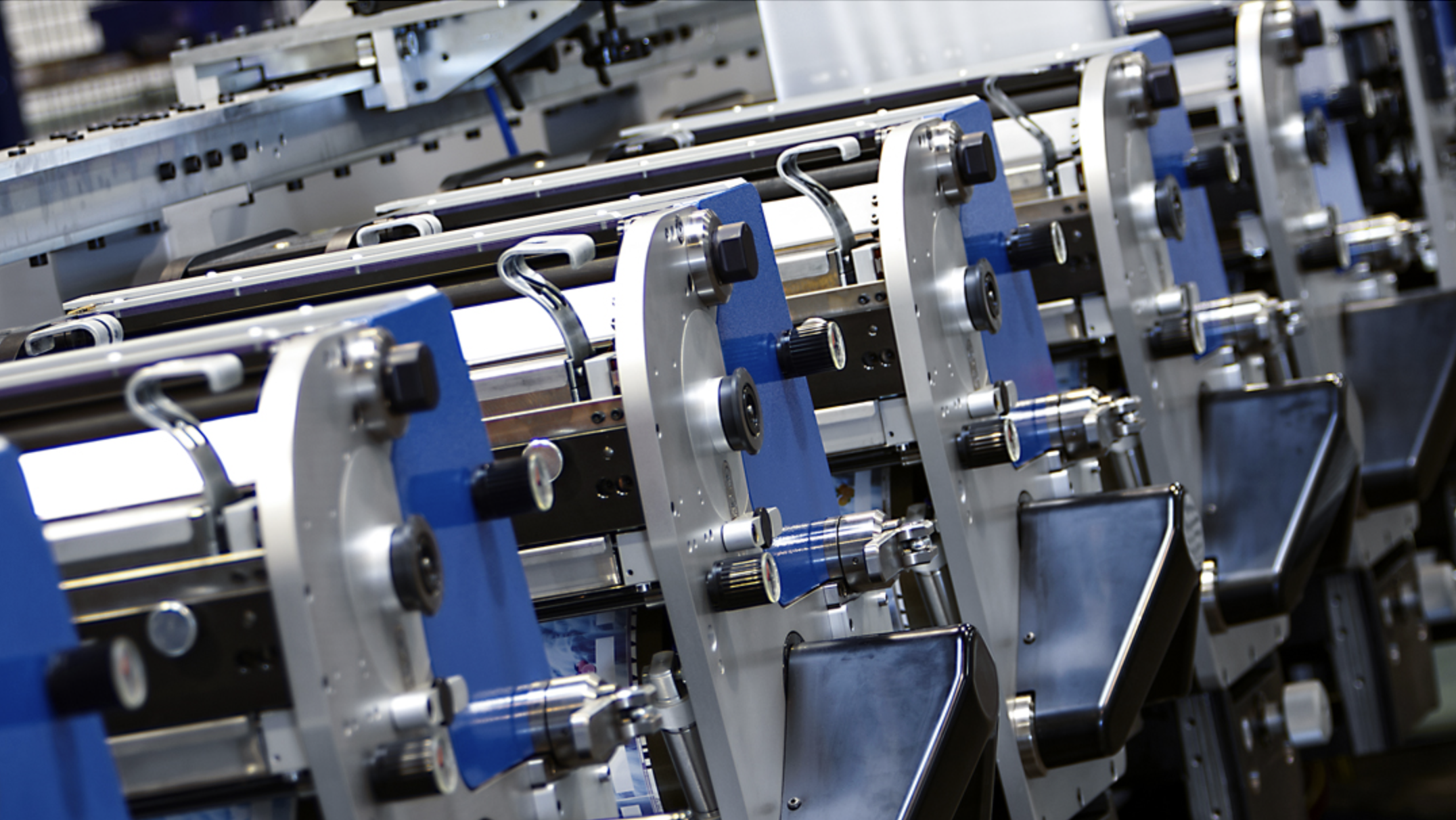

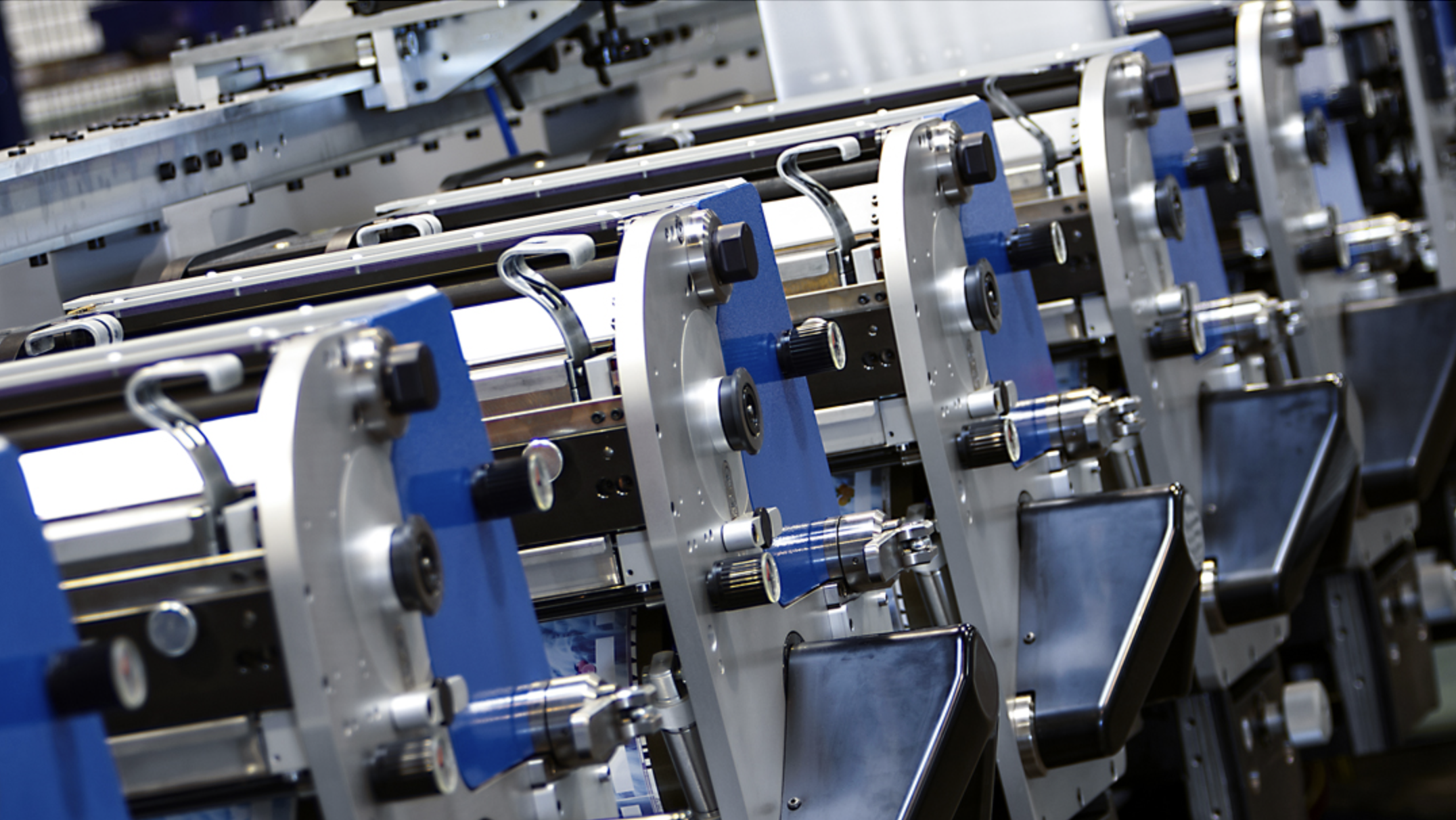

The Gallus ECS 340 is a smooth-running, user-friendly, and extremely economical printing press for commodity labels. With a range of features focused on the essentials, the press can be freely expanded in modules of two. Its technical granite core makes it particularly durable and gives it exceptional smoothness.

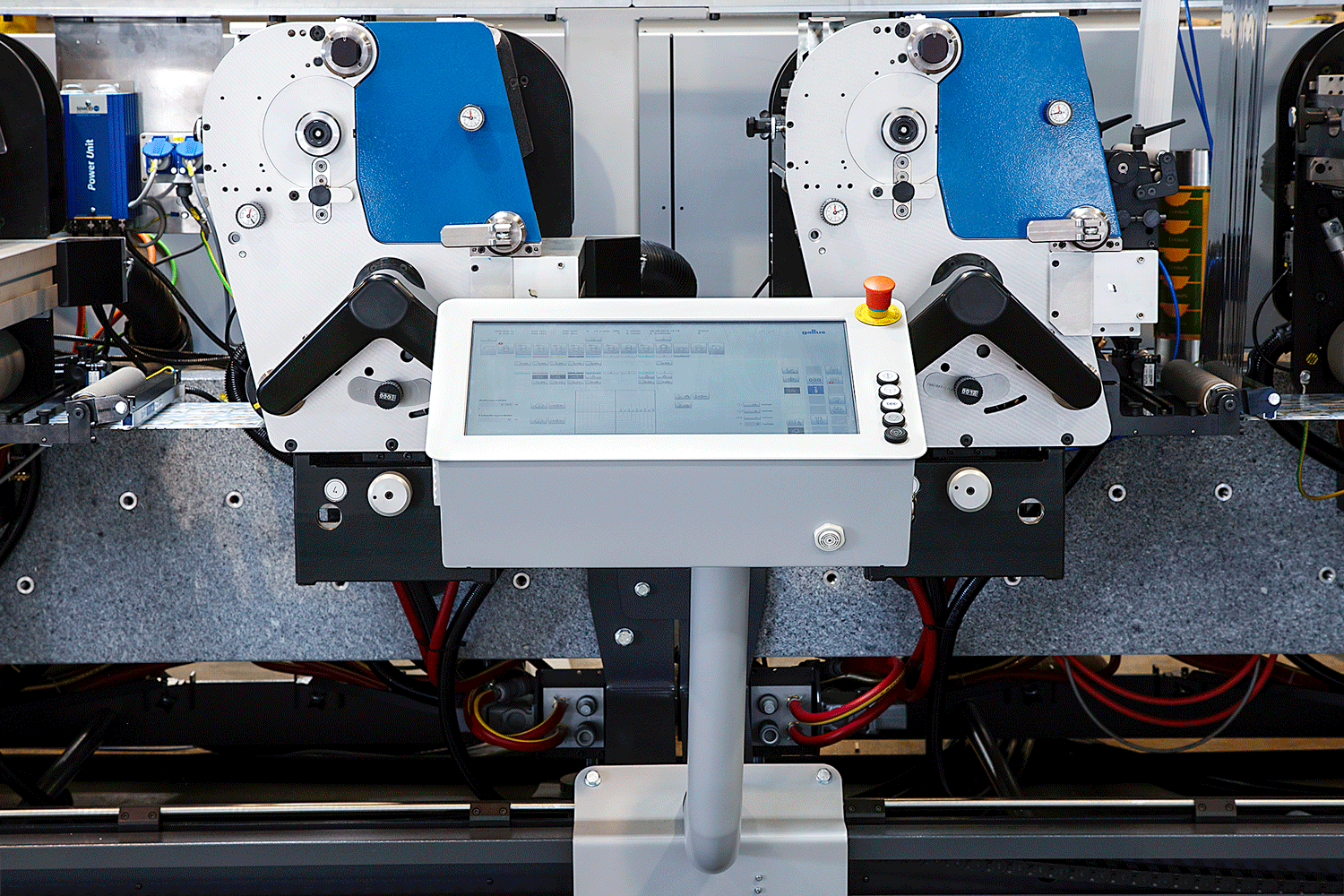

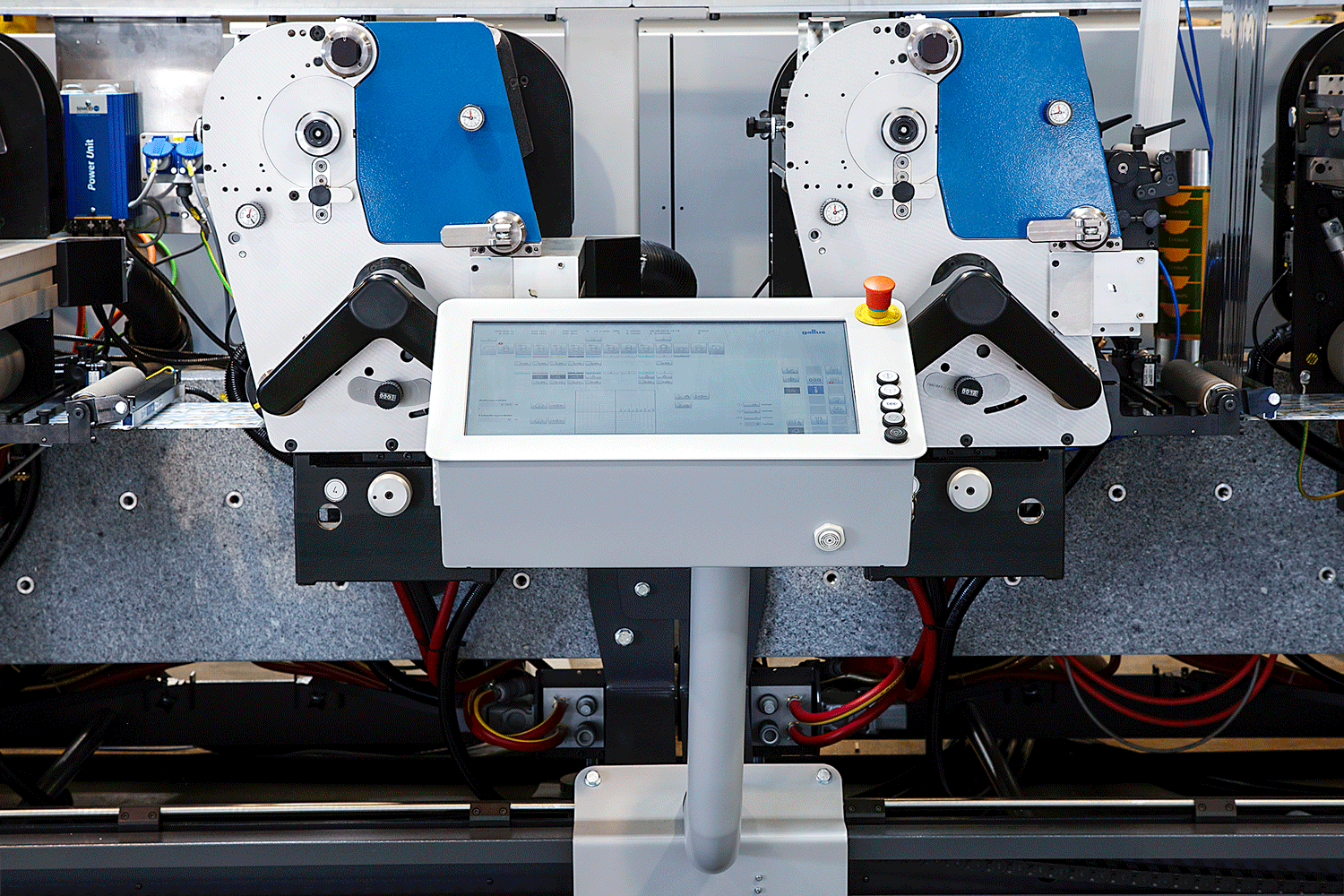

Equipped with state-of-the-art technology, the Gallus ECS 340 is optimally equipped for extremely efficient operation. The combination of servo drives with automation functions such as presetting, register control and dynamic print delivery is unique. This interaction ensures both the high productivity of the Gallus ECS 340 and consistent, easily reproducible quality at the highest level.

Consistent quality in execution makes all the difference when printing with the Gallus ECS 340. This is just one reason for the enormous success of this short-web label printing press, which has been the best-selling press in its class since its introduction. In the label printing industry, the name Gallus stands for quality and precision.

Label production at top speed and extremely low cost: that's the Gallus ECS 340. With the shortest web travel in the label printing industry and high machine efficiency, waste during production is massively reduced. Even at high speeds, the Gallus ECS 340 impresses with its extremely smooth running. This is based on the machine's solid, robust granite core, which has excellent damping properties.

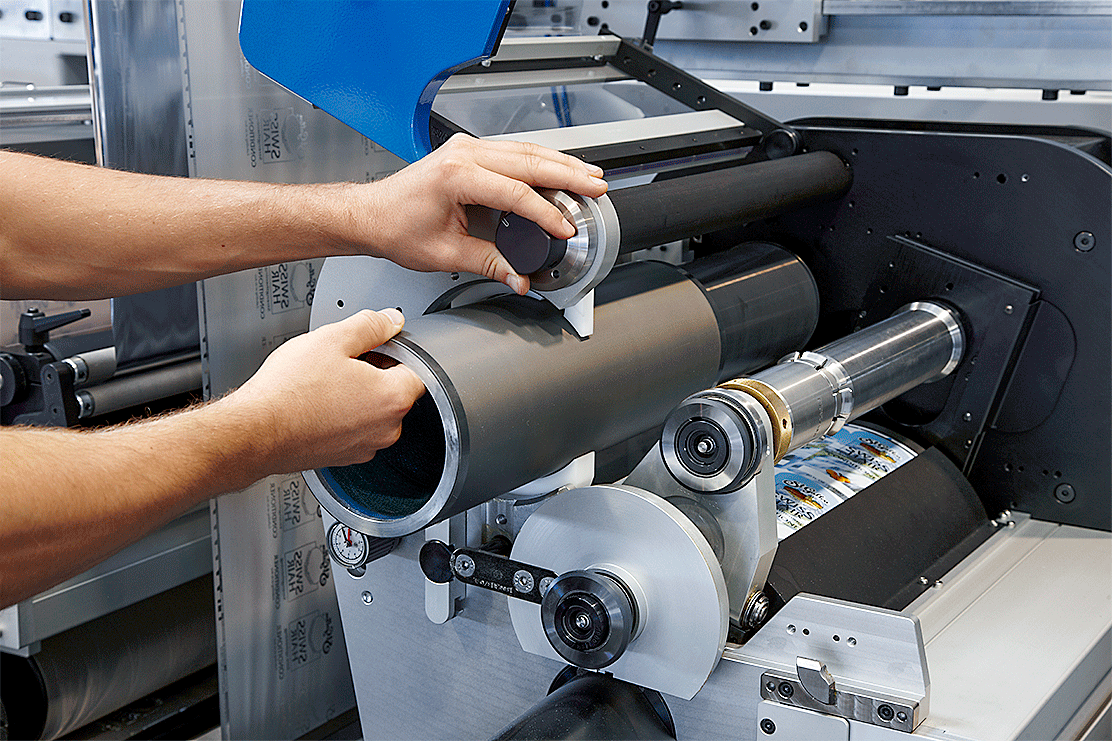

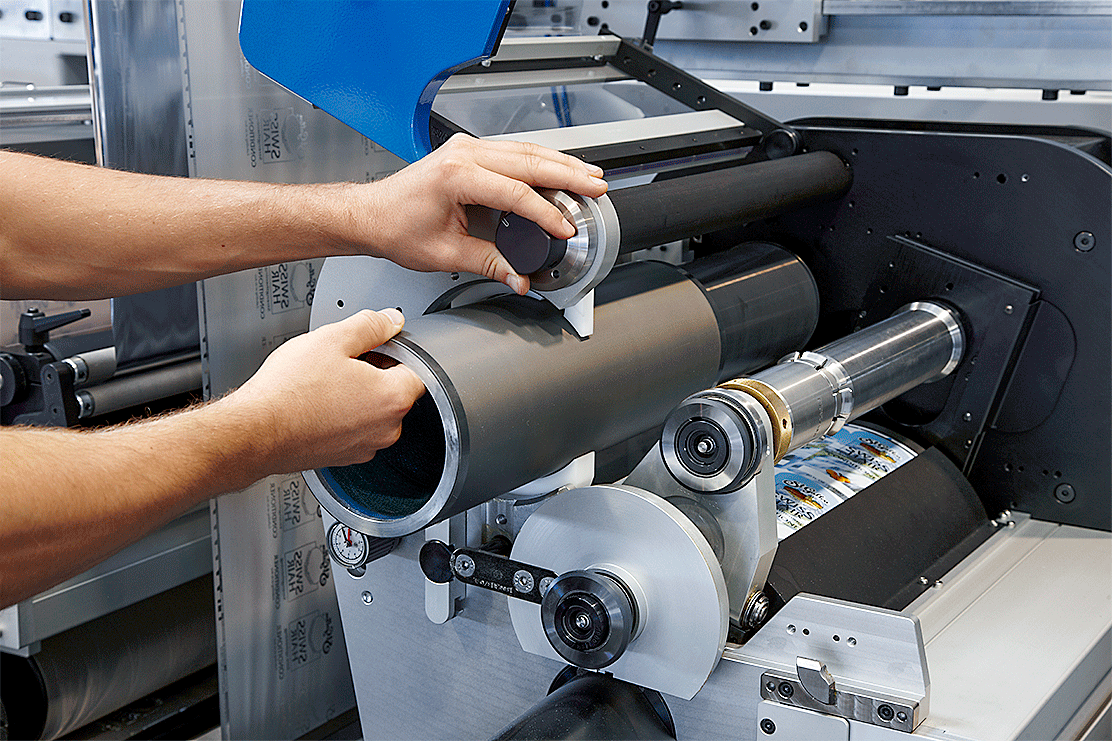

A material that is neither electrically conductive nor magnetic, thus counteracting static charges on the machine. Designed as a modular system, the Gallus ECS 340 can be freely expanded at any time in modules of two. This allows flexible use for numerous different applications and finishes such as flexo and screen printing, cold foil or rotary die cutting. In addition, the Gallus ECS 340 uses proven Gallus sleeve technology: aluminum printing cylinder sleeves guarantee high print quality with consistent reproducibility and maximum aging resistance throughout their entire service life.

| Machine speed, mechanical, max. | 165 m/min. | 541 ft/min. |

| Maximum track width | 340 mm | 13.4" |

| Maximum print width | 340 mm | 13.4" |

| Maximum format length | 508 mm | 20" |

| Minimum format length | *1) 254 mm | *1) 10 " |

| Maximum number of printing operations | 12 |

| UV |

| Hot air drying |

| Maximum track width | 340 mm | 13 3/8" |

| Maximum processing width | 340 mm | 13.4" |

| Maximum format length | 508 mm | 20" |

| Minimum format length | 254 mm | 10" |

| Maximum number of processing operations | 4 |

| Adhesive composites | 50-200 µ commercially available |

| Paper | 50-250 µ commercially available |

| Cardboard | upon request |

| Monofoil label materials | upon request |

| Tube laminates | upon request |

| HEIRES access |

| All technical specifications are approximate values. We reserve the right to make design changes. *1) Sieve from 269.9 mm / 10 5/8" |