08/25/2021

The total cost of label production is determined by three key factors: quality, cost, and productivity. These factors cannot be considered in isolation, although this does happen in practice due to the complexity involved. While there are clear ideas about the achievable quality and costs of a label printing machine in the run-up to an investment decision, productivity is often given too little consideration in a purchase decision, taking into account process variability. The following example shows how significant the influence of this criterion is on total operating costs.

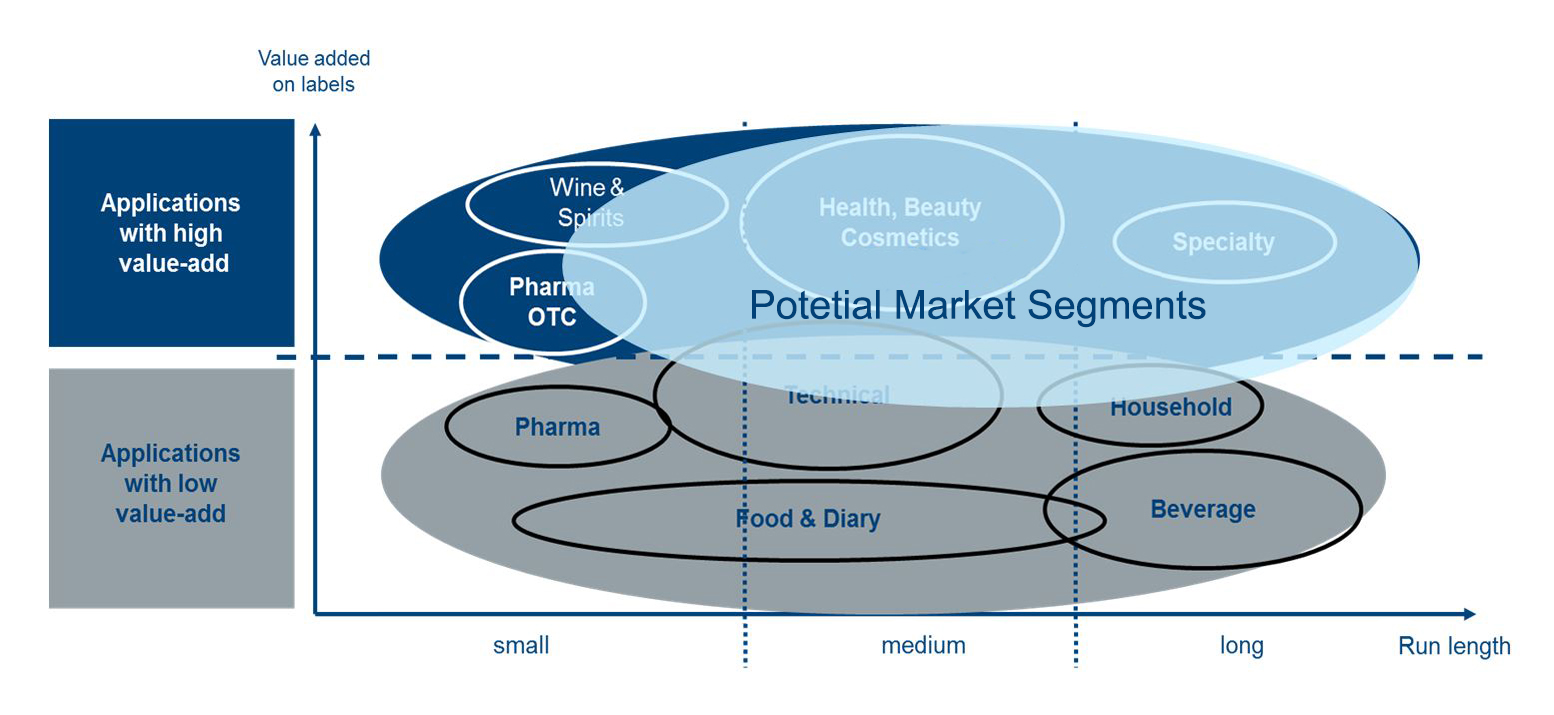

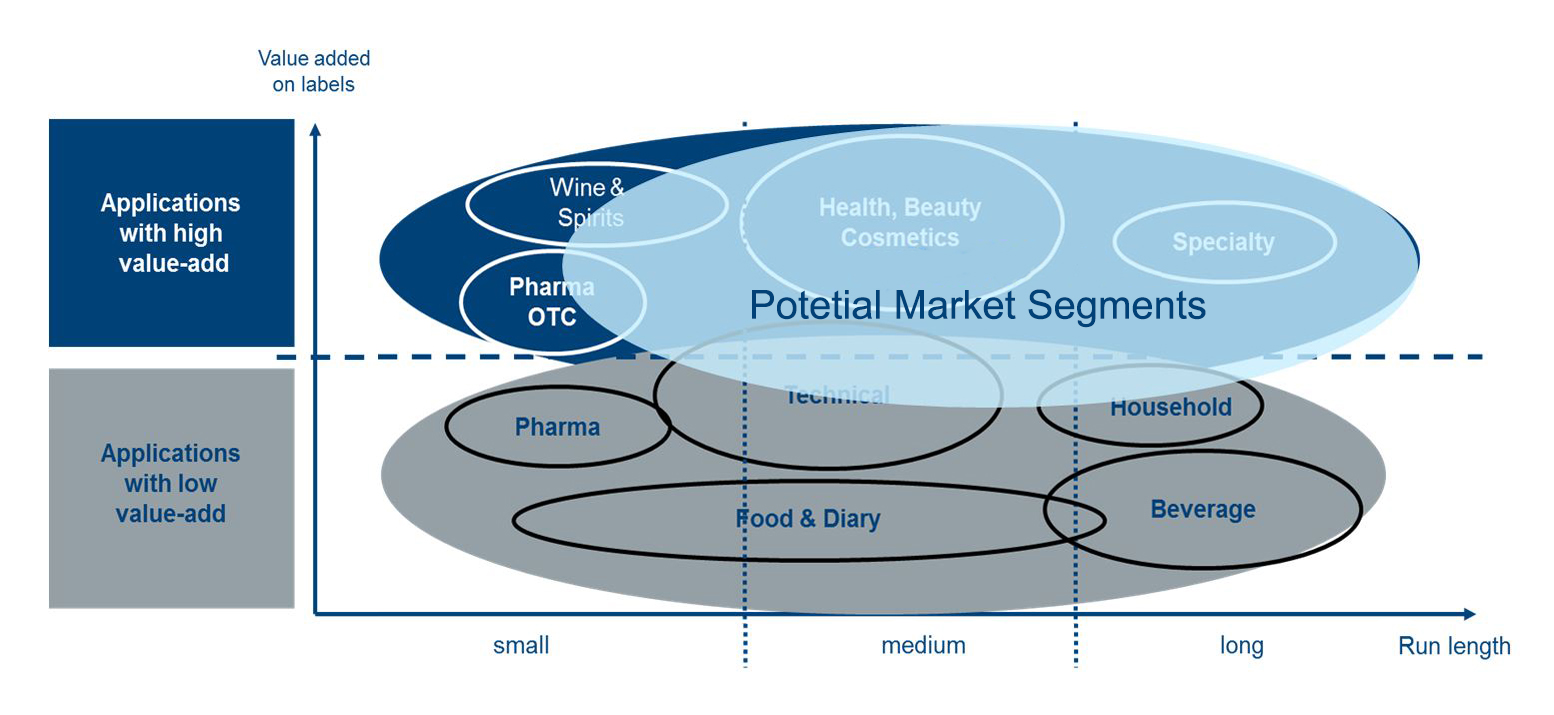

When planning an investment, the market segments in which the machine is to be used are the starting point for a detailed analysis. According to the results of the analysis in this example, the market and customer structure consists mainly of customers operating in the cosmetics, wine and spirits, and over-the-counter (OTC) pharmaceuticals segments, as well as orders in security printing, e.g., tax stamps for tobacco. This results in the potential market segments for which the machine is configured. The aim is to find a machine system that meets the specific requirements of these market segments. It should also be noted that all of the market segments mentioned are characterized by small to medium and high run lengths, i.e., a high number of orders with many different printing processes and substrates.

Analysis of market segments at the start of an investment decision (source: Gallus Ferd. Rüesch AG)

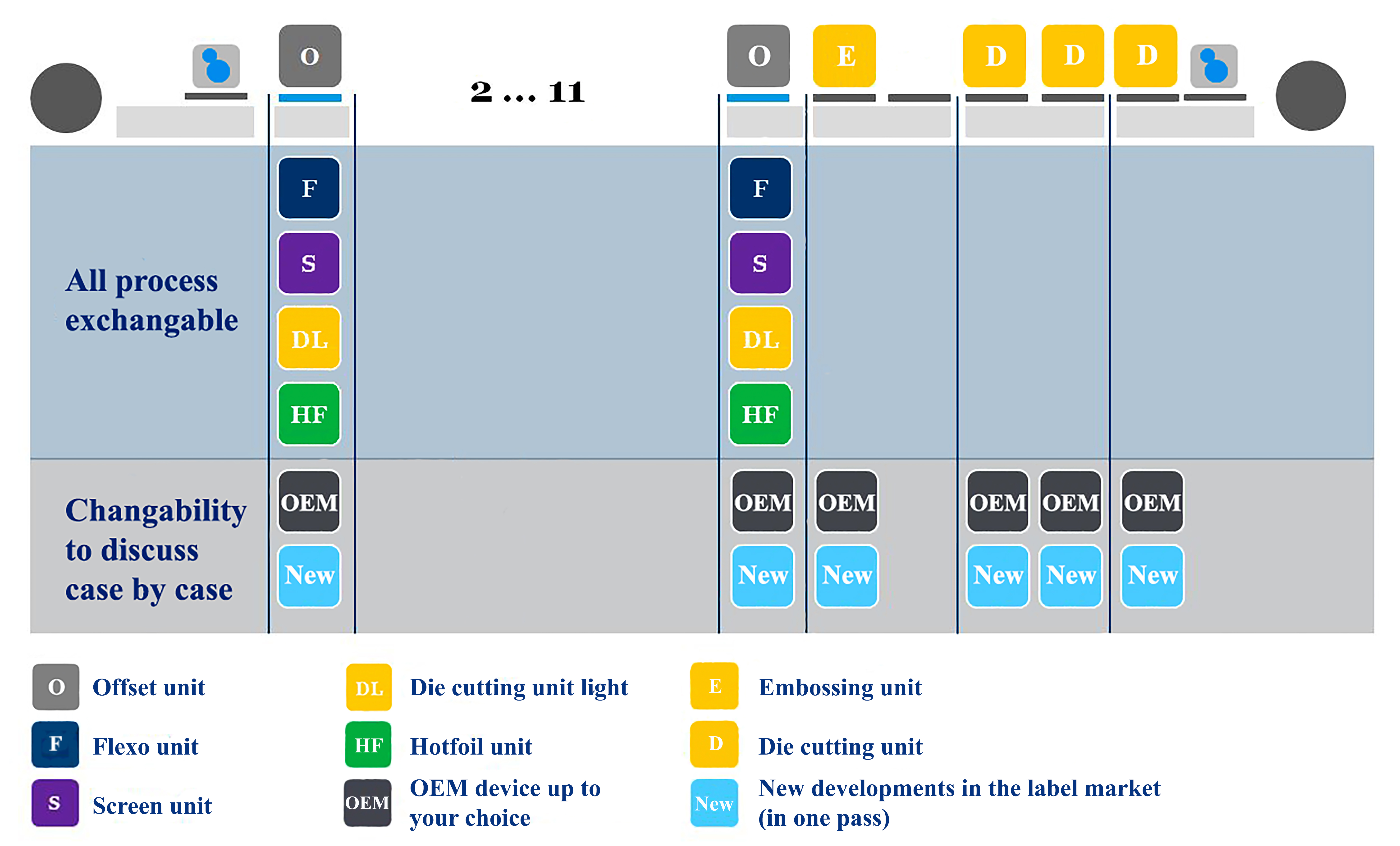

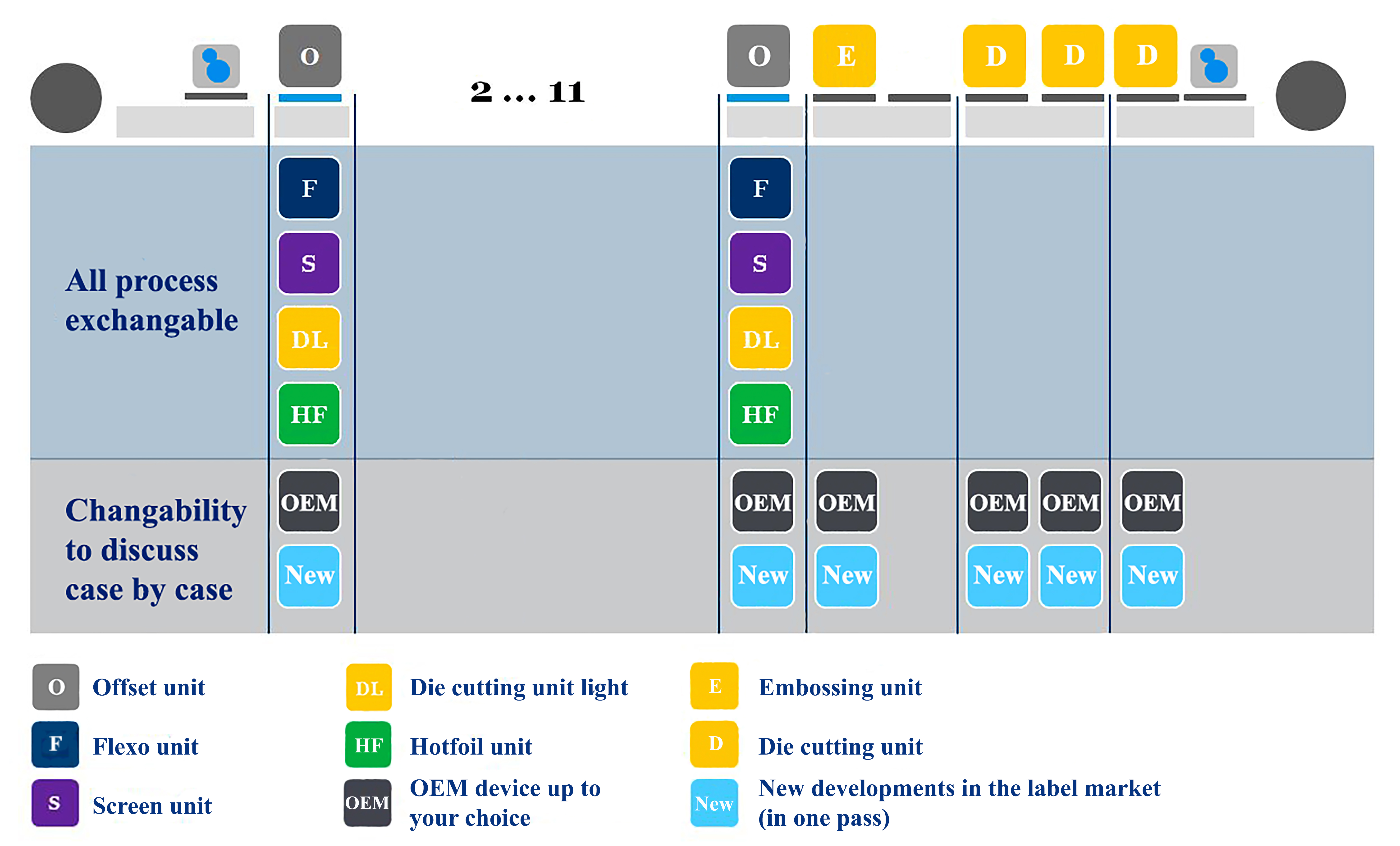

In order to meet the wide range of requirements identified, a freely configurable and expandable machine system with a high degree of automation is necessary. Such machine systems are available on the market from various manufacturers. For illustrative purposes, two of the most commonly used machine types on the market are used as references.

The machine from manufacturer A – the Gallus RCS 430 – has a maximum printing width of 430 mm (17") with a specified maximum machine speed of 160 m/min, while the machine from manufacturer B has a maximum printing width of 410 mm (16") and a maximum machine speed of 170 m/min.

Both machines can be configured individually or in combination with all printing units such as offset, flexo, and rotary screen printing, hot foil stamping, and cold foil printing to meet the requirements of the aforementioned market segments. They are each equipped with a web tension control system that is also suitable for tube laminates up to 450 µm thick in the cosmetics sector.

In this example, all offset printing units can be replaced by flexographic printing units, screen printing units, die cutting units, or hot foil units. Replacement with units from OEM manufacturers is also possible. (Source: Gallus Ferd. Rüesch AG)

Both machines can be configured with gravure printing units and, in a comparative test, meet the requirements for print quality and user-friendliness. They feature a high degree of automation for print supply and register and offer the option of retrieving machine settings from the working memory for repeat jobs and via automatic washing systems.

In a nutshell, from a technical point of view, the machines have comparable equipment, but they differ in terms of acquisition costs. The price of machine B is approximately 20% lower than the price of machine A, which means that, taking into account the criteria listed, the purchase decision would clearly favor machine B.

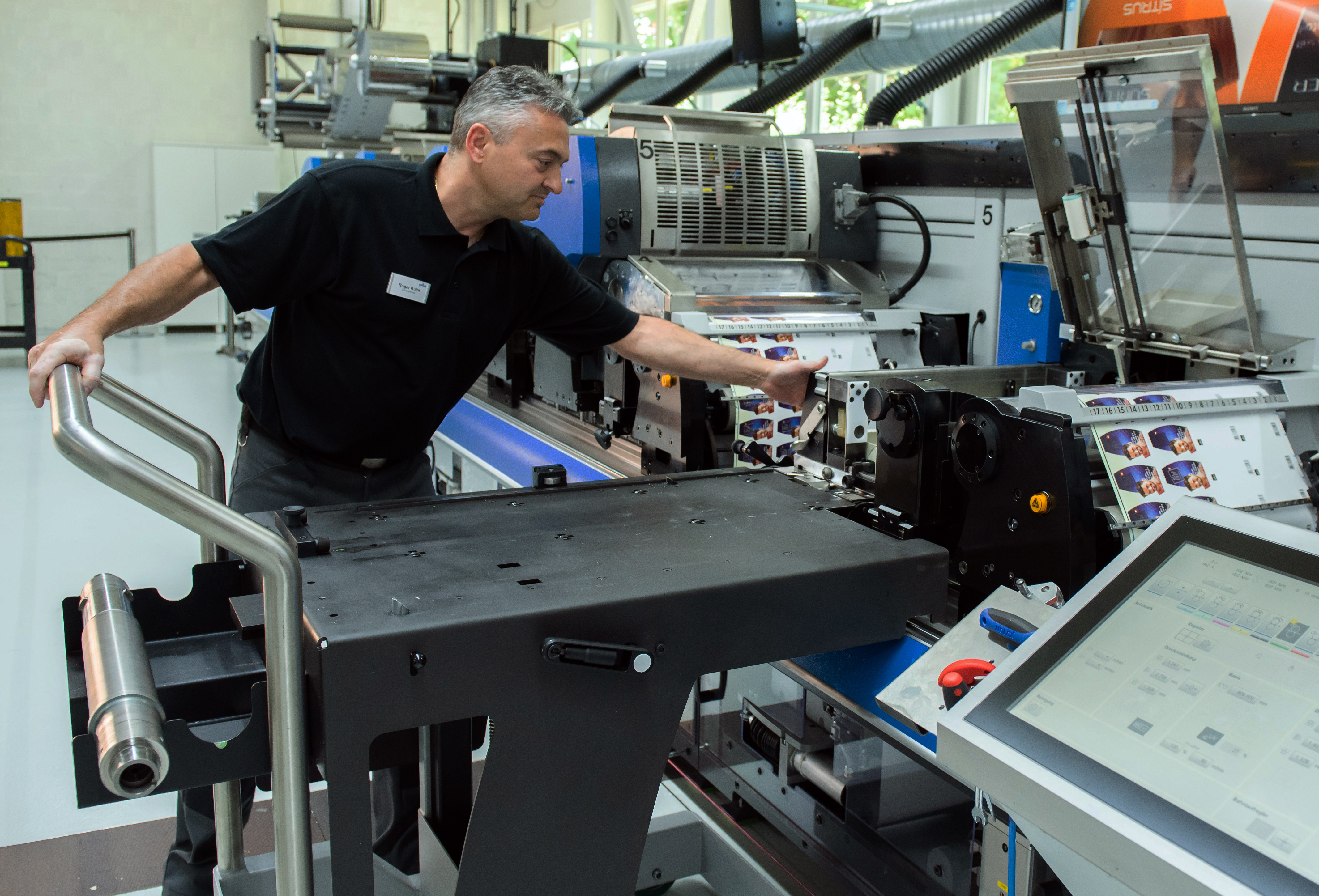

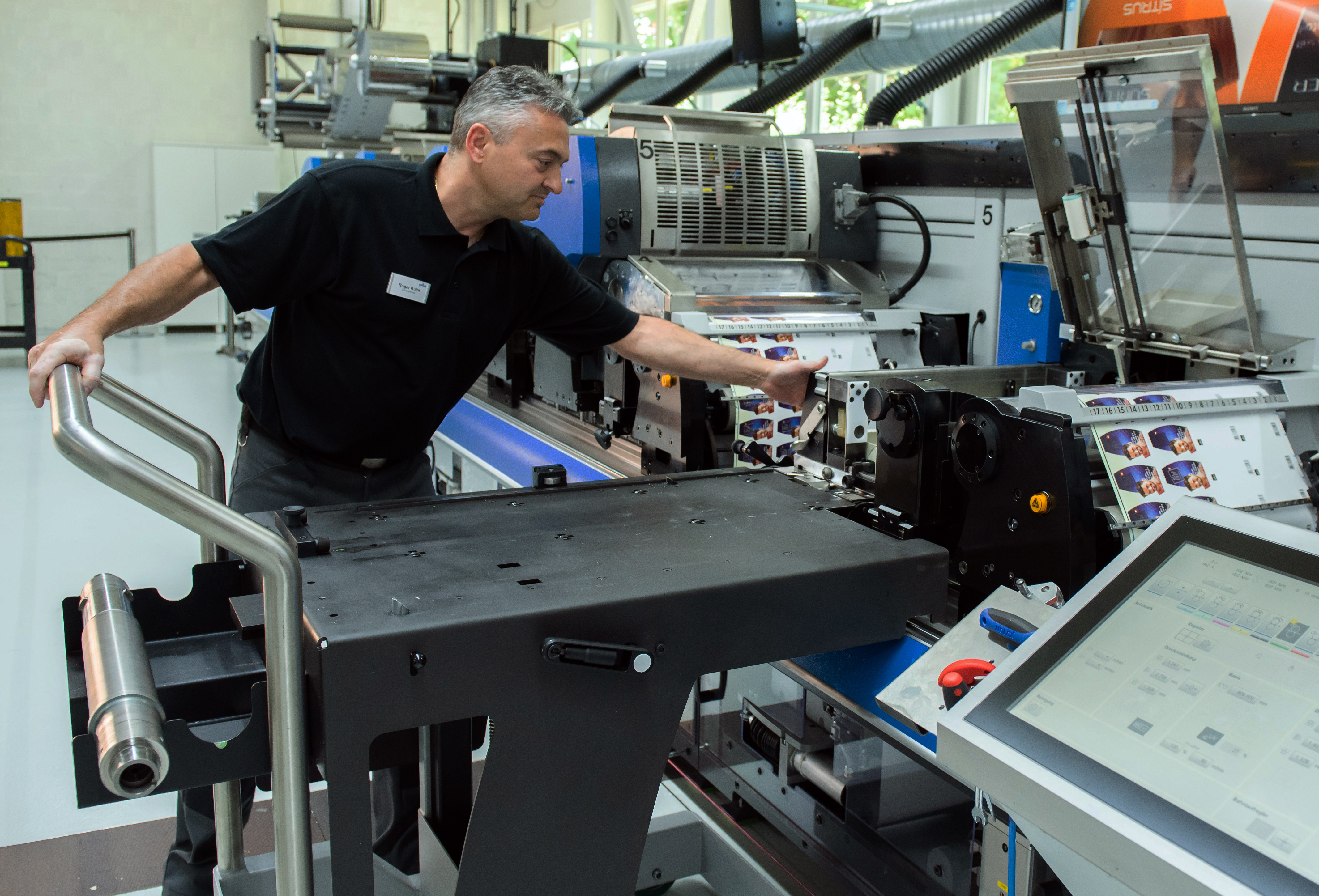

Process variability is a decisive factor in overall operating costs: The Gallus RCS 430 scores not only with its modularity, but above all with process changeover times of less than 5 minutes (source: illustration courtesy of Gallus Ferd. Rüesch AG).

Market segments such as cosmetics and wine labels require a high number of process changes per shift in label printing. For wine labels, four process changes per shift are the norm, and in some cases there can even be up to seven process changes. For this reason, the changeover times for a process change are becoming increasingly important in terms of economic efficiency. On machine A, for example, process changes can be made while the machine is running, meaning that printing units that are not needed for the current job can already be set up for the next job.

If, as in the given order structure, many process changes are required, i.e., print products from different printing processes are exchanged with each other, the total process changeover times have a significant impact on the cost-effectiveness of a machine system in label printing.

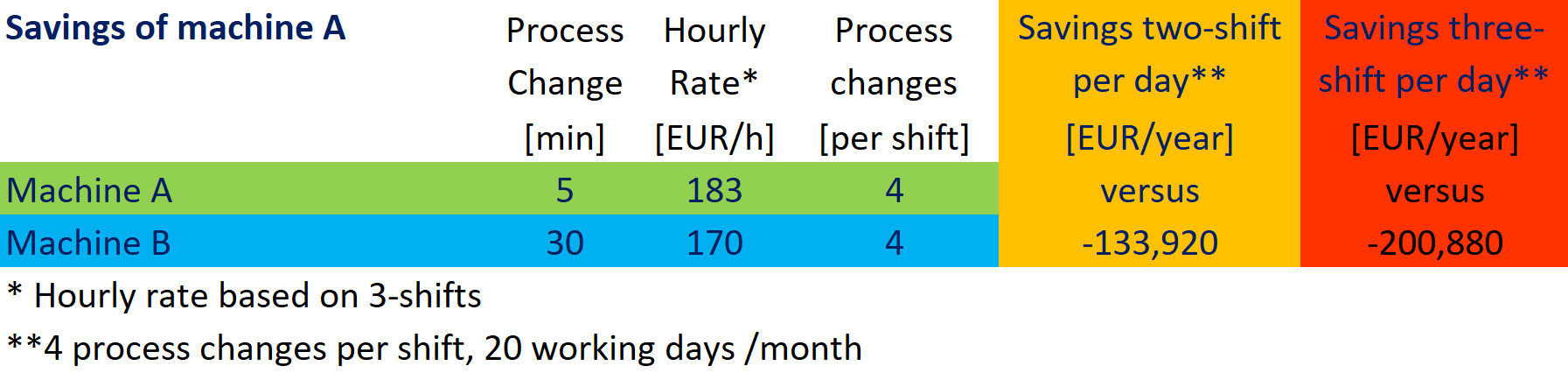

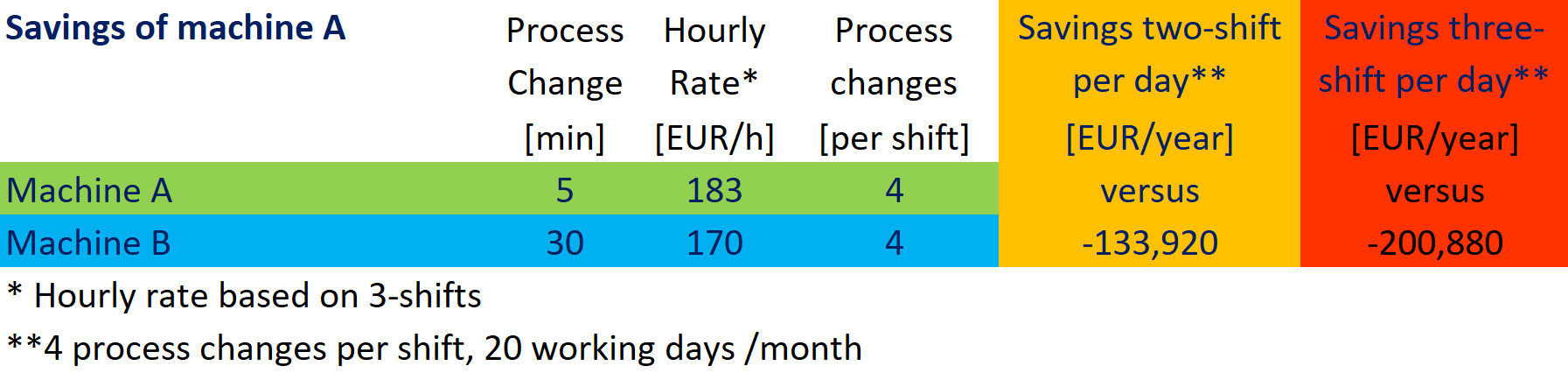

In terms of process changeover times themselves – and this is often underestimated when making investment decisions – the two reference machines differ significantly. The changeover time for a process change on machine A is 5 minutes, without web separation and with fully automatic setup and changeover carts, while on machine B it is 30 minutes. With a corresponding number of process changes, this difference has a significant impact on the cost-effectiveness of a machine system.

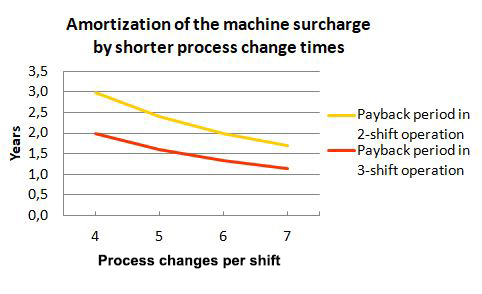

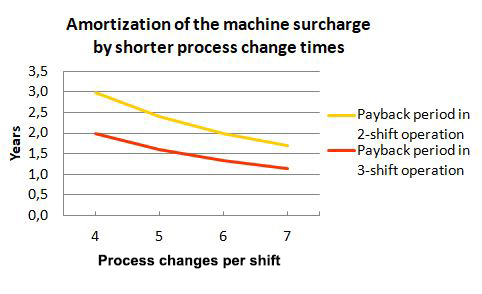

Cost-effectiveness A TCO calculator (Total Cost of Ownership calculator), which machine manufacturers use for cost comparisons, can be used to determine which machine system with its specific acquisition costs offers the highest cost-effectiveness for the specified order structure and the assumed average number of 4 process changes per shift. This shows that a higher purchase price for a machine can be amortized in a relatively short time if the process changeover time of the machine system is lower. If, for example, the machines differ in purchase price by EUR 400,000, the higher acquisition costs are amortized in this example after two to a maximum of three years of operation, depending on whether a machine is operated in two or three shifts, thanks to savings in process changes during daily operation. This amortization period assumes that the system is operating at full capacity.

An additional advantage is that with machine A, the material web does not have to be separated during a process change, which means additional material savings. With an average of 12 m of web lost per process change, this results in a further saving of approx. EUR 7,000 per year in three-shift operation with four process changes per shift. These material savings alone significantly reduce the payback period for the additional cost of machine A.

A higher number of process changes per shift reduces the amortization period for the additional machine cost. With five process changes, for example, the additional cost is amortized in 3-shift operation after approximately 1.5 years (based on 20 working days/month at a machine hourly rate of EUR 183/hour). (Source: Gallus Ferd. Rüesch AG)

A process change, i.e. changing one printing unit for another, takes less than 5 minutes on machine A until it is ready to print. (Source: Gallus Ferd. Rüesch AG)

The more complex a print product is, the more frequent process changes are required in production, because depending on the job requirements, an application may require the use of printing units in different positions. In the beauty segment, the most common process changes are from flexo to screen printing and vice versa, but an offset printing unit often has to be replaced with flexo, screen printing, or a hot foil embossing unit. For example, screen printing is used for opaque white, fine lettering, or for underlaying white. Flexographic printing is used for cost-effective application of inks and coatings, as well as for printing special colors.

A closer analysis reveals that machine A and machine B are only comparable at first glance. When making an investment, it is not only the total investment and the achievable quality that are decisive, but also the overall performance.

In addition to qualitative aspects, the process variability of the machine system is essential in this context, especially with frequent process changes. The reason is simple: fast process changeovers and setup times have a decisive influence on overall operating costs. This influence is further amplified by smaller and smaller orders. Especially with an order structure involving many changes, it is therefore worthwhile investing in a highly automated, flexible label printing system such as the Gallus RCS 430, despite the higher acquisition costs. Under these conditions, the supposedly more expensive machine proves to be the more economical solution.

08/25/2021

The total cost of label production is determined by three key factors: quality, cost, and productivity. These factors cannot be considered in isolation, although this does happen in practice due to the complexity involved. While there are clear ideas about the achievable quality and costs of a label printing machine in the run-up to an investment decision, productivity is often given too little consideration in a purchase decision, taking into account process variability. The following example shows how significant the influence of this criterion is on total operating costs.

When planning an investment, the market segments in which the machine is to be used are the starting point for a detailed analysis. According to the results of the analysis in this example, the market and customer structure consists mainly of customers operating in the cosmetics, wine and spirits, and over-the-counter (OTC) pharmaceuticals segments, as well as orders in security printing, e.g., tax stamps for tobacco. This results in the potential market segments for which the machine is configured. The aim is to find a machine system that meets the specific requirements of these market segments. It should also be noted that all of the market segments mentioned are characterized by small to medium and high run lengths, i.e., a high number of orders with many different printing processes and substrates.

Analysis of market segments at the start of an investment decision (source: Gallus Ferd. Rüesch AG)

In order to meet the wide range of requirements identified, a freely configurable and expandable machine system with a high degree of automation is necessary. Such machine systems are available on the market from various manufacturers. For illustrative purposes, two of the most commonly used machine types on the market are used as references.

The machine from manufacturer A – the Gallus RCS 430 – has a maximum printing width of 430 mm (17") with a specified maximum machine speed of 160 m/min, while the machine from manufacturer B has a maximum printing width of 410 mm (16") and a maximum machine speed of 170 m/min.

Both machines can be configured individually or in combination with all printing units such as offset, flexo, and rotary screen printing, hot foil stamping, and cold foil printing to meet the requirements of the aforementioned market segments. They are each equipped with a web tension control system that is also suitable for tube laminates up to 450 µm thick in the cosmetics sector.

In this example, all offset printing units can be replaced by flexographic printing units, screen printing units, die cutting units, or hot foil units. Replacement with units from OEM manufacturers is also possible. (Source: Gallus Ferd. Rüesch AG)

Both machines can be configured with gravure printing units and, in a comparative test, meet the requirements for print quality and user-friendliness. They feature a high degree of automation for print supply and register and offer the option of retrieving machine settings from the working memory for repeat jobs and via automatic washing systems.

In a nutshell, from a technical point of view, the machines have comparable equipment, but they differ in terms of acquisition costs. The price of machine B is approximately 20% lower than the price of machine A, which means that, taking into account the criteria listed, the purchase decision would clearly favor machine B.

Process variability is a decisive factor in overall operating costs: The Gallus RCS 430 scores not only with its modularity, but above all with process changeover times of less than 5 minutes (source: illustration courtesy of Gallus Ferd. Rüesch AG).

Market segments such as cosmetics and wine labels require a high number of process changes per shift in label printing. For wine labels, four process changes per shift are the norm, and in some cases there can even be up to seven process changes. For this reason, the changeover times for a process change are becoming increasingly important in terms of economic efficiency. On machine A, for example, process changes can be made while the machine is running, meaning that printing units that are not needed for the current job can already be set up for the next job.

If, as in the given order structure, many process changes are required, i.e., print products from different printing processes are exchanged with each other, the total process changeover times have a significant impact on the cost-effectiveness of a machine system in label printing.

In terms of process changeover times themselves – and this is often underestimated when making investment decisions – the two reference machines differ significantly. The changeover time for a process change on machine A is 5 minutes, without web separation and with fully automatic setup and changeover carts, while on machine B it is 30 minutes. With a corresponding number of process changes, this difference has a significant impact on the cost-effectiveness of a machine system.

Cost-effectiveness A TCO calculator (Total Cost of Ownership calculator), which machine manufacturers use for cost comparisons, can be used to determine which machine system with its specific acquisition costs offers the highest cost-effectiveness for the specified order structure and the assumed average number of 4 process changes per shift. This shows that a higher purchase price for a machine can be amortized in a relatively short time if the process changeover time of the machine system is lower. If, for example, the machines differ in purchase price by EUR 400,000, the higher acquisition costs are amortized in this example after two to a maximum of three years of operation, depending on whether a machine is operated in two or three shifts, thanks to savings in process changes during daily operation. This amortization period assumes that the system is operating at full capacity.

An additional advantage is that with machine A, the material web does not have to be separated during a process change, which means additional material savings. With an average of 12 m of web lost per process change, this results in a further saving of approx. EUR 7,000 per year in three-shift operation with four process changes per shift. These material savings alone significantly reduce the payback period for the additional cost of machine A.

A higher number of process changes per shift reduces the amortization period for the additional machine cost. With five process changes, for example, the additional cost is amortized in 3-shift operation after approximately 1.5 years (based on 20 working days/month at a machine hourly rate of EUR 183/hour). (Source: Gallus Ferd. Rüesch AG)

A process change, i.e. changing one printing unit for another, takes less than 5 minutes on machine A until it is ready to print. (Source: Gallus Ferd. Rüesch AG)

The more complex a print product is, the more frequent process changes are required in production, because depending on the job requirements, an application may require the use of printing units in different positions. In the beauty segment, the most common process changes are from flexo to screen printing and vice versa, but an offset printing unit often has to be replaced with flexo, screen printing, or a hot foil embossing unit. For example, screen printing is used for opaque white, fine lettering, or for underlaying white. Flexographic printing is used for cost-effective application of inks and coatings, as well as for printing special colors.

A closer analysis reveals that machine A and machine B are only comparable at first glance. When making an investment, it is not only the total investment and the achievable quality that are decisive, but also the overall performance.

In addition to qualitative aspects, the process variability of the machine system is essential in this context, especially with frequent process changes. The reason is simple: fast process changeovers and setup times have a decisive influence on overall operating costs. This influence is further amplified by smaller and smaller orders. Especially with an order structure involving many changes, it is therefore worthwhile investing in a highly automated, flexible label printing system such as the Gallus RCS 430, despite the higher acquisition costs. Under these conditions, the supposedly more expensive machine proves to be the more economical solution.