03/03/2016

In our series "Practical experience in label printing," we address everyday challenges in label printing and how to solve them. In this issue, we focus on the topic of "overprinting of the printing plate."

Problem identification:

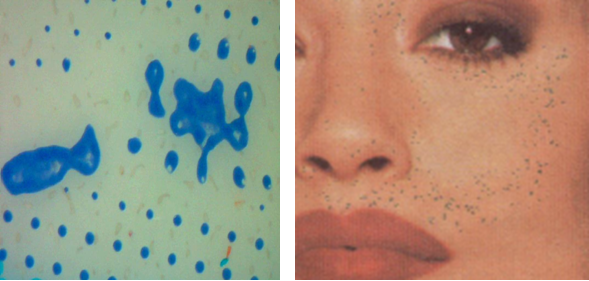

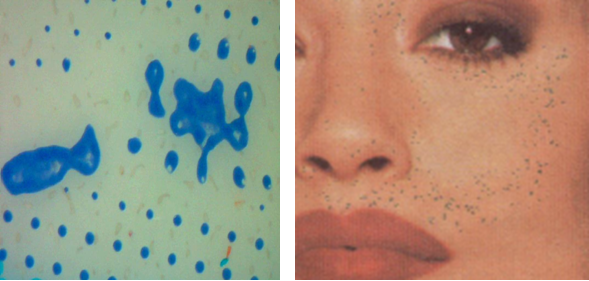

The fine grid areas ("highlights") smear and must be cleaned regularly. Under the microscope, individual dots connect.

Troubleshooting:

03/03/2016

In our series "Practical experience in label printing," we address everyday challenges in label printing and how to solve them. In this issue, we focus on the topic of "overprinting of the printing plate."

Problem identification:

The fine grid areas ("highlights") smear and must be cleaned regularly. Under the microscope, individual dots connect.

Troubleshooting: