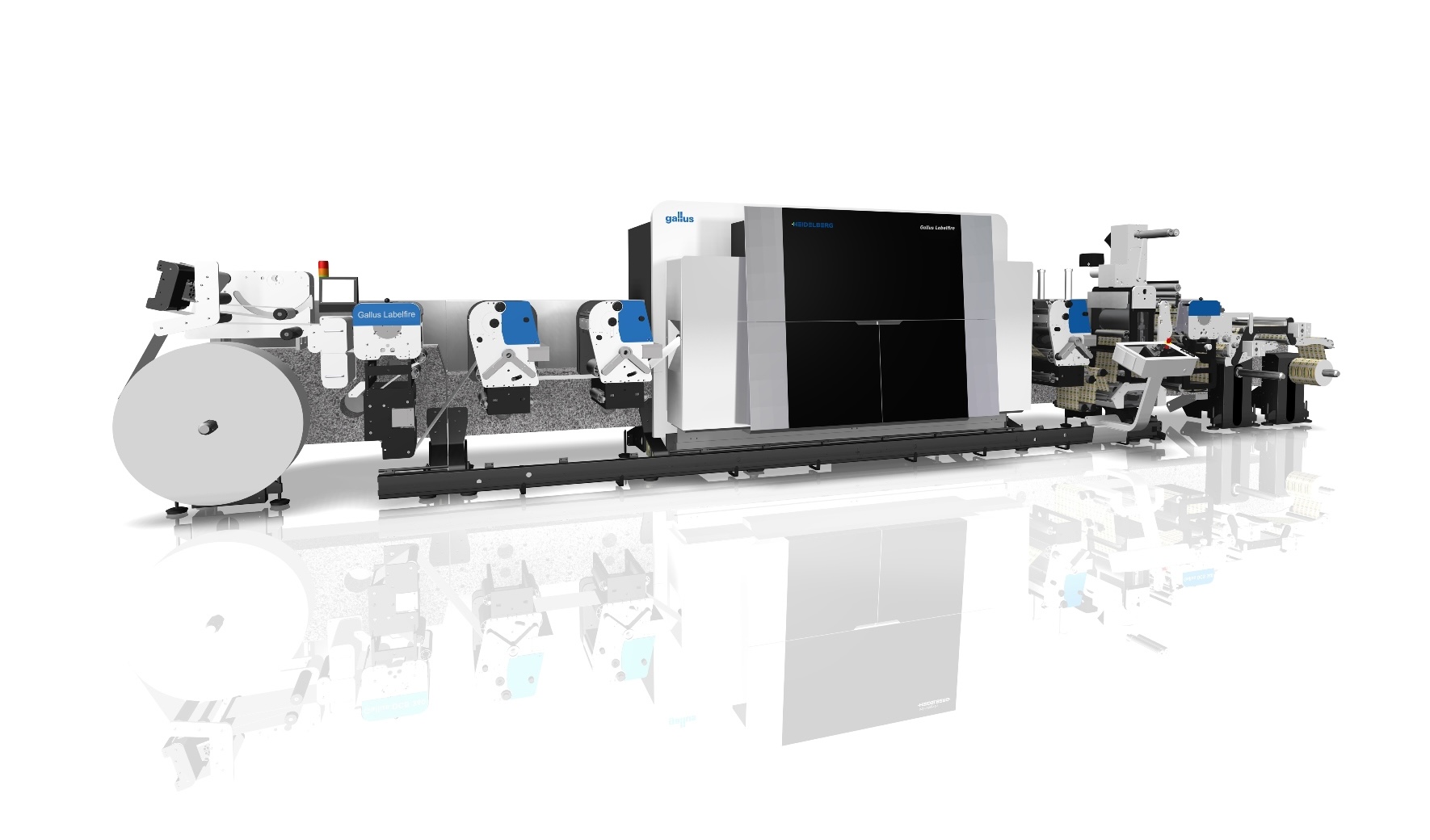

The Gallus Labelfire is now available in a low-migration version, enabling the production of food-grade packaging in accordance with EU regulations and the Swiss Ordinance on Commodities (Swiss Ordinance).

Gallus and Heidelberg have developed a special ink series that is suitable for packaging that comes into contact with food. The drying and curing technology of the Labelfire has also been adapted to comply with European regulations.

Thomas Schweizer Head of Business and Product Management at Gallus Ferd. Rüesch AG.

Gallus Labelfire Low Migration means that label and packaging printing is possible with UV inkjet using specially developed Saphira UVLM inks. These are designed to meet food industry standards. In addition, the digital printing press is equipped with a multi-stage drying system.

Compliance with the relevant legislation is a prerequisite for the food-grade production of labels and packaging.

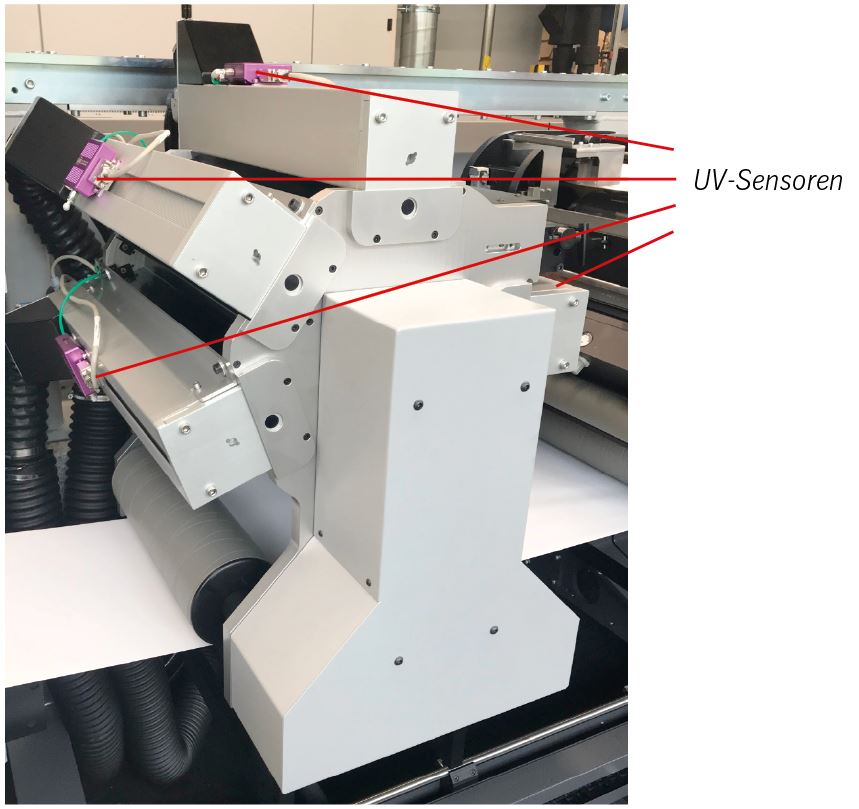

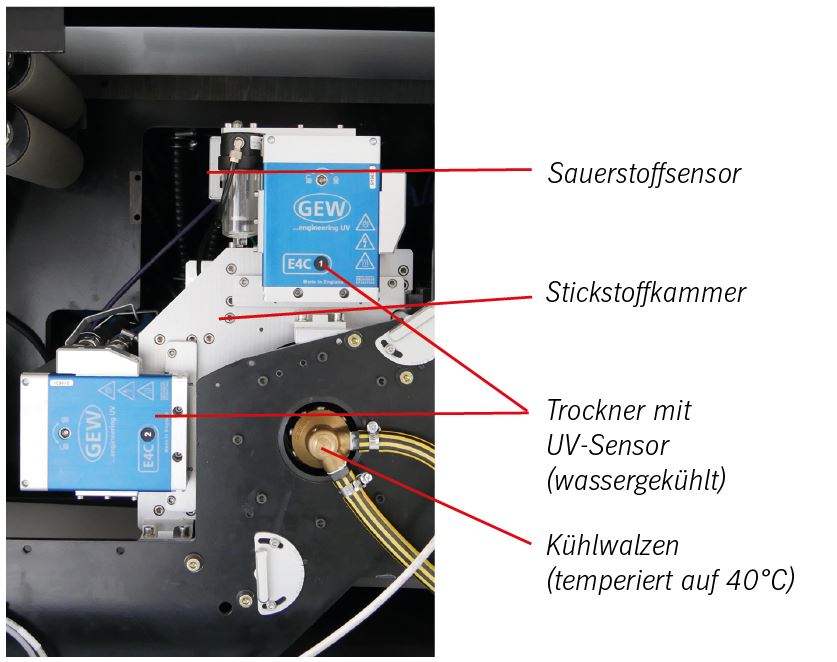

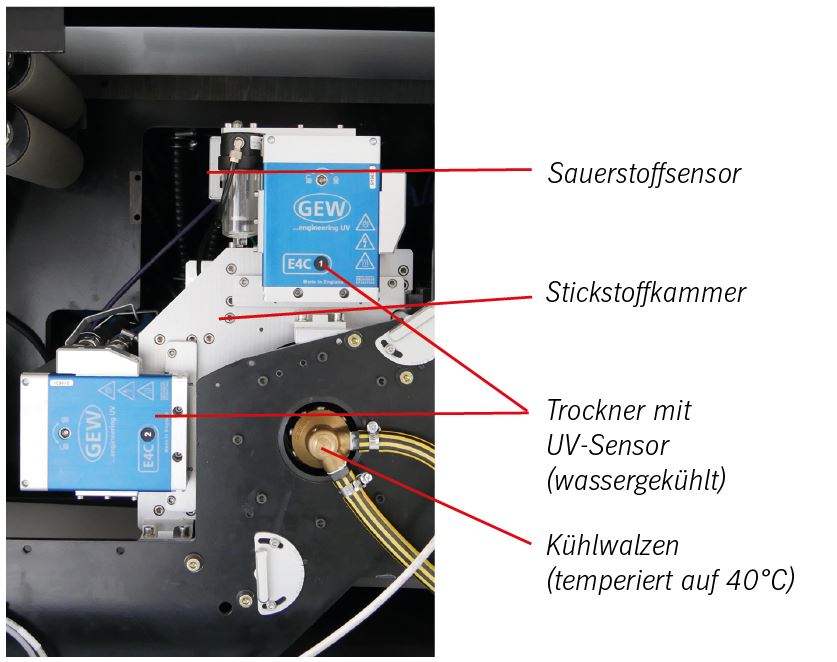

Immediately after printing, the substrate web is fed into a dryer with an inert chamber. The almost complete exclusion of oxygen optimizes the curing performance of the inks. An optional UV booster then enhances the drying of the inks at higher printing speeds.

In addition to these new drying units, the Gallus Labelfire Low Migration is equipped with UV and oxygen sensors that display the production parameters.

Our UVLM inks comply with:

At higher pressure speeds, the drying unit is additionally supported by a booster with four nozzles.

Uwe Alexander, Digital Product Manager, Gallus

The new drying unit has two inert chambers and is equipped with UV and oxygen sensors.

| Printing process | UV - Piezo DoD - InkJet |

| Print speed | up to 50 m/min |

| Productivity | Max. printing area 1020 m²/h |

| Print resolution | 1200 x 1200 dpi native @2pl droplet size Optical resolution approx. 2400 x 2400 dpi, > 200 grayscale levels |

| Number of digital print modules | Number of digital print modules |

| Gallus LabelFire 340 |

|

| Colors Gallus Labelfire 340 | 4 to 8 colors Depending on the configuration: CMYK + GOV (green/orange/violet) + digital white, CMYK + GOV, CYMK + digital white, CYMK) |

| Maximum print width | 340 mm |

| Substrates* | Monofilms, papers, and composite materials 50 - 350 µm |

| Special substrates* | Cardboard, tube laminates, and thin films 20 - 450 µm |

| Dimensions (L x W x H) | 11,500 x 4,500 x 2,200 mm (basic configuration) |

| Variable data | iVDP (industrial variable data processing, such as barcodes, QR codes, alphanumeric text, etc.) Fully variable data printing (optional): for 100% variable data printing at full resolution, full color gamut, and full machine speed. |

| Interfaces | for all common pre-press software solutions |

| Low migration | EU Regulations No. 10/2011, No. 1935/2004, No. 2023/2006 (GMP), Swiss Ordinance, Nestlé Guidance, EuPIA, GMP |

| Wheel diameter | max. 40" (1016 mm) |

| Number of conventional process platforms | max. 5 + punching |

| Format length flexo unit | 254 - 508 mm |

| Substrate conditioning | Track cleaning (direct contact + contactless), corona, antistatic and primer (if necessary), flexographic printing (full and spot colors), delam-relam, reverse printing, screen printing, cold foil |

| Inline processing | Flexographic printing, screen printing, varnishing, cold foil, laminating, die cutting, grid winding, longitudinal cutting, Digital Embellishment Unit (DEU) |

| Punch | Semi-rotary, format length: 152 - 508 mm (6'' - 20'') ; Fully rotary, format length: 152 - 508 mm (6'' - 20'') |

| Connected load | (3P + PE) 96 kW** or 121 kW*** |

| Excitement | 400V / 50Hz (optional 60 Hz) |

| Compressed air | 350 l/min; with 7.5 to max. 10 bar, oil- and water-free |

| Exhaust air | Approx. 2323 m3/h** or 3812 m3/h*** Exhaust air temperature max. 50°C / Ozone emission during operation approx. 0.8 mg/m3 |

| Conformity | CE, GS (UL on request) |

| Remote diagnosis | Yes |

| All technical specifications are approximate values. We reserve the right to make design changes. |

| *Substratesand their printing depend on many factors in the low-migration version. Please consult our Gallus experts if you have any specific questions. **Example A | Without booster (2x flexo + DPU + 2x flexo) ***Example B | With booster (2x flexo + DPU + booster + 2x flexo) |