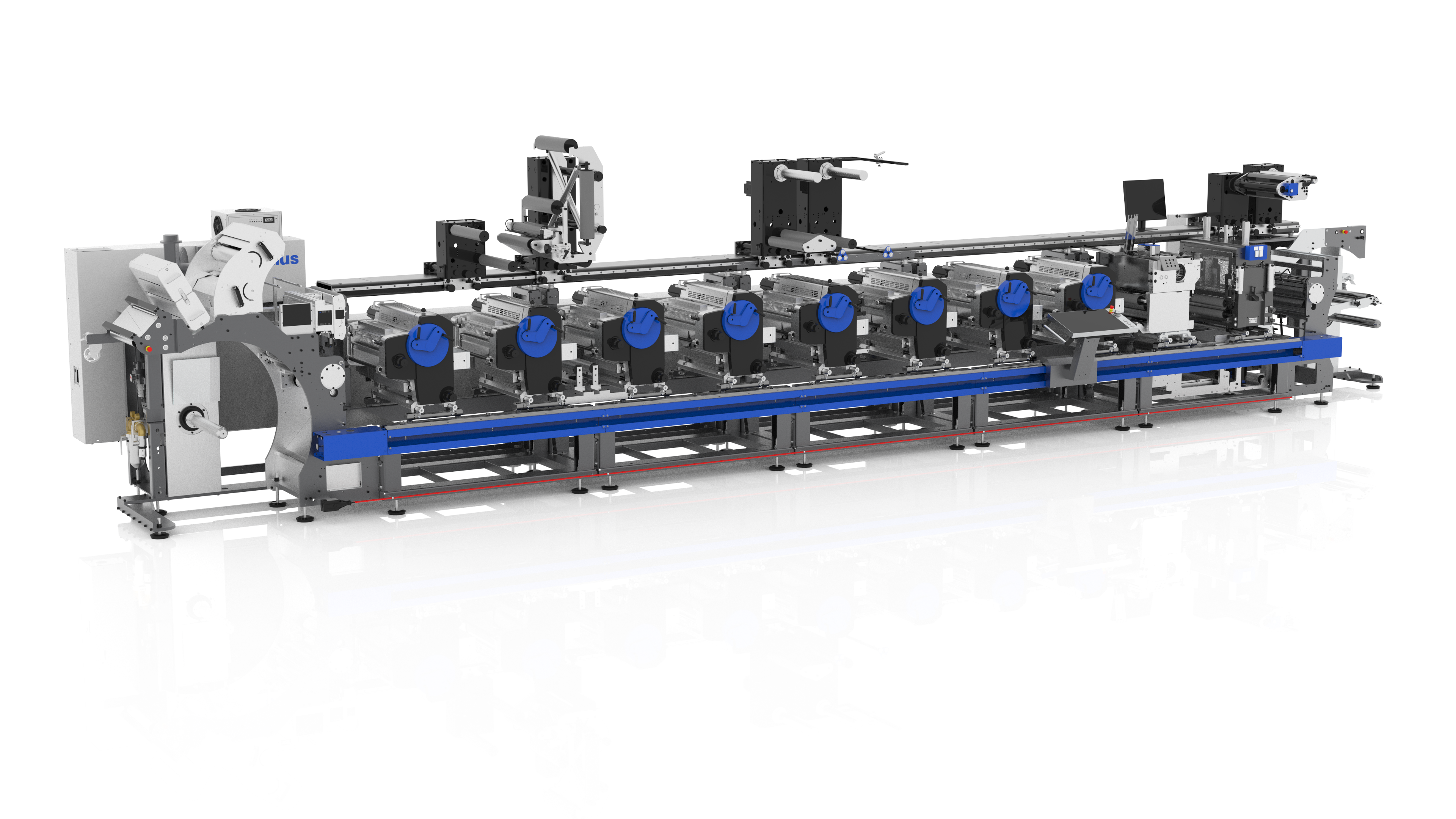

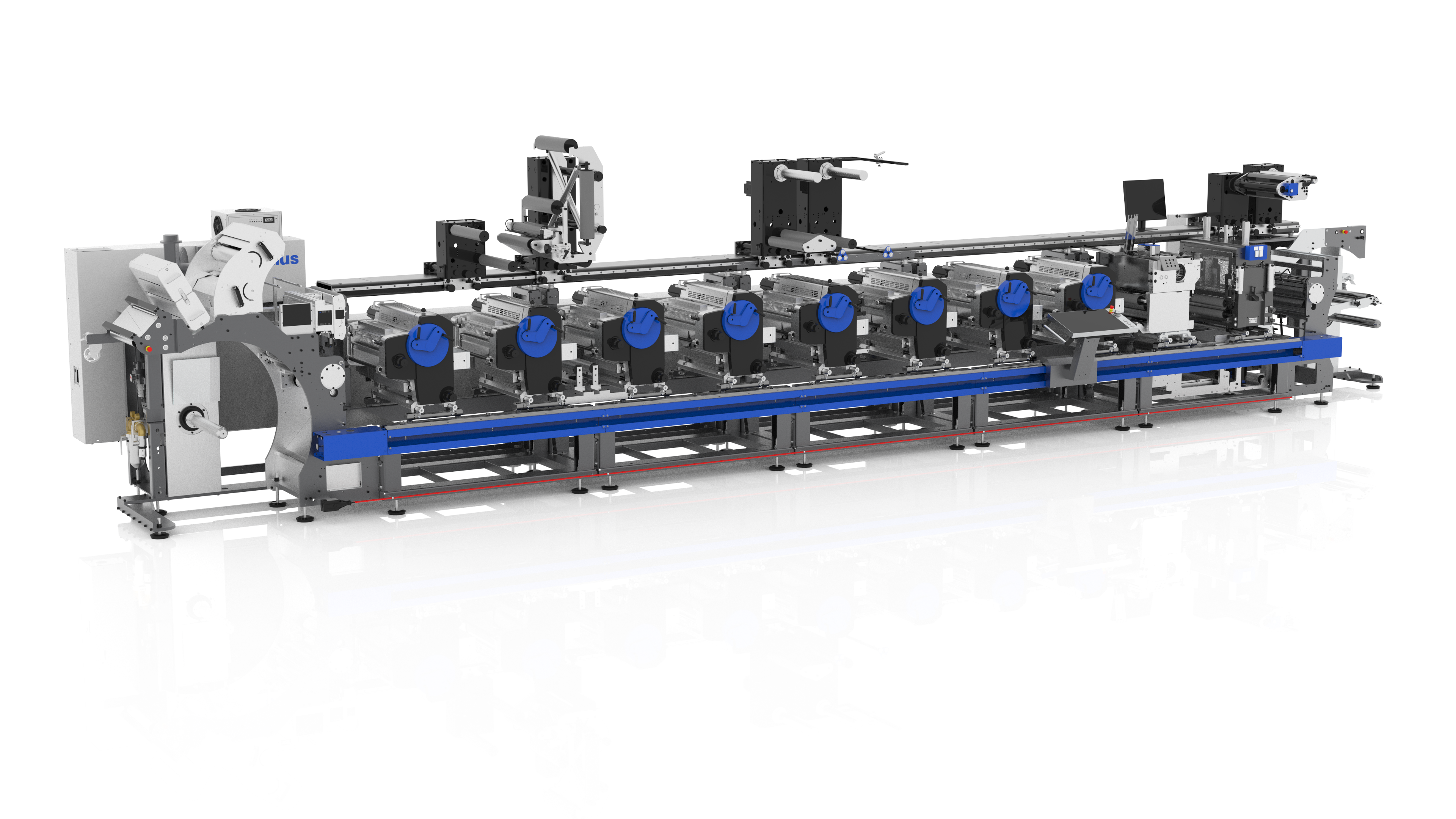

The Gallus Labelmaster gives printing companies in the label and packaging market unprecedented flexibility – now and in the future. This is made possible by the revolutionary platform design, which allows all customer-specific requirements to be met individually. Various printing modules are available for this purpose, allowing the Gallus Labelmaster to be configured individually depending on the model: precisely tailored to every business model.

A short web path of only 1.4 m from printing unit to printing unit, short makeready and setup times, extremely fast job changes, and perfect register reduce waste right from the start. An optimized ink fountain for the chamber doctor blade requires only 250 g of ink, which also keeps costs low. In addition, the ink fountain has been improved in terms of ink spitting and foaming – for reliably high printing speeds. With the Gallus Labelmaster, you increase your profitability.

True to this motto, the unique modularity of the Gallus Labelmaster covers all common requirements in today's and tomorrow's markets: from commodity labels to sophisticated, high-quality finished labels. Depending on the model line, modules can be freely selected, linked together and thus the machine can be customized to meet any requirements.

Gallus Labelmaster

The basic version offers excellent value for money and a high degree of flexibility.

This basic model offers an optional feature that limits the number of printing process changes to two positions with full integration into the control system.

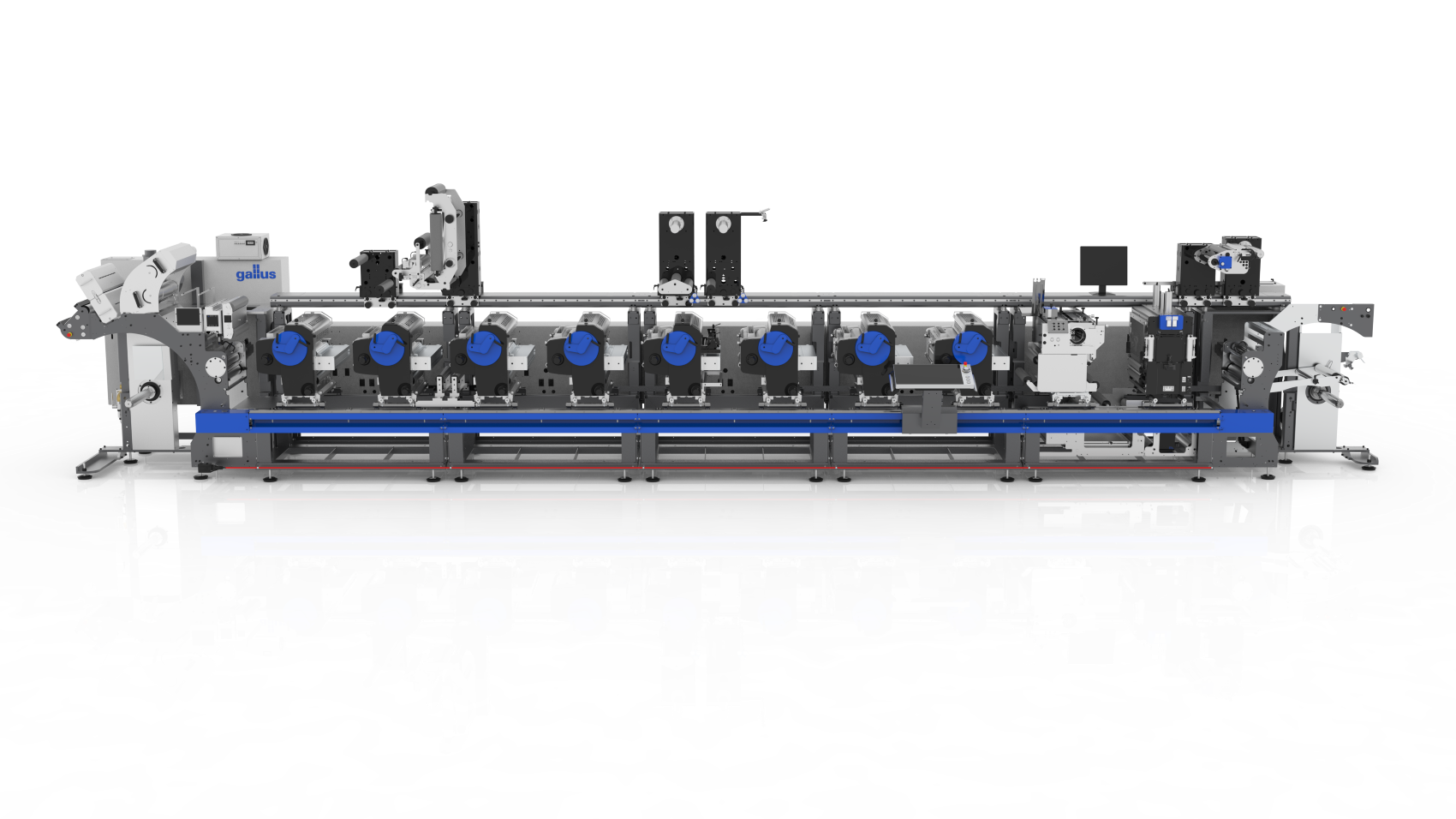

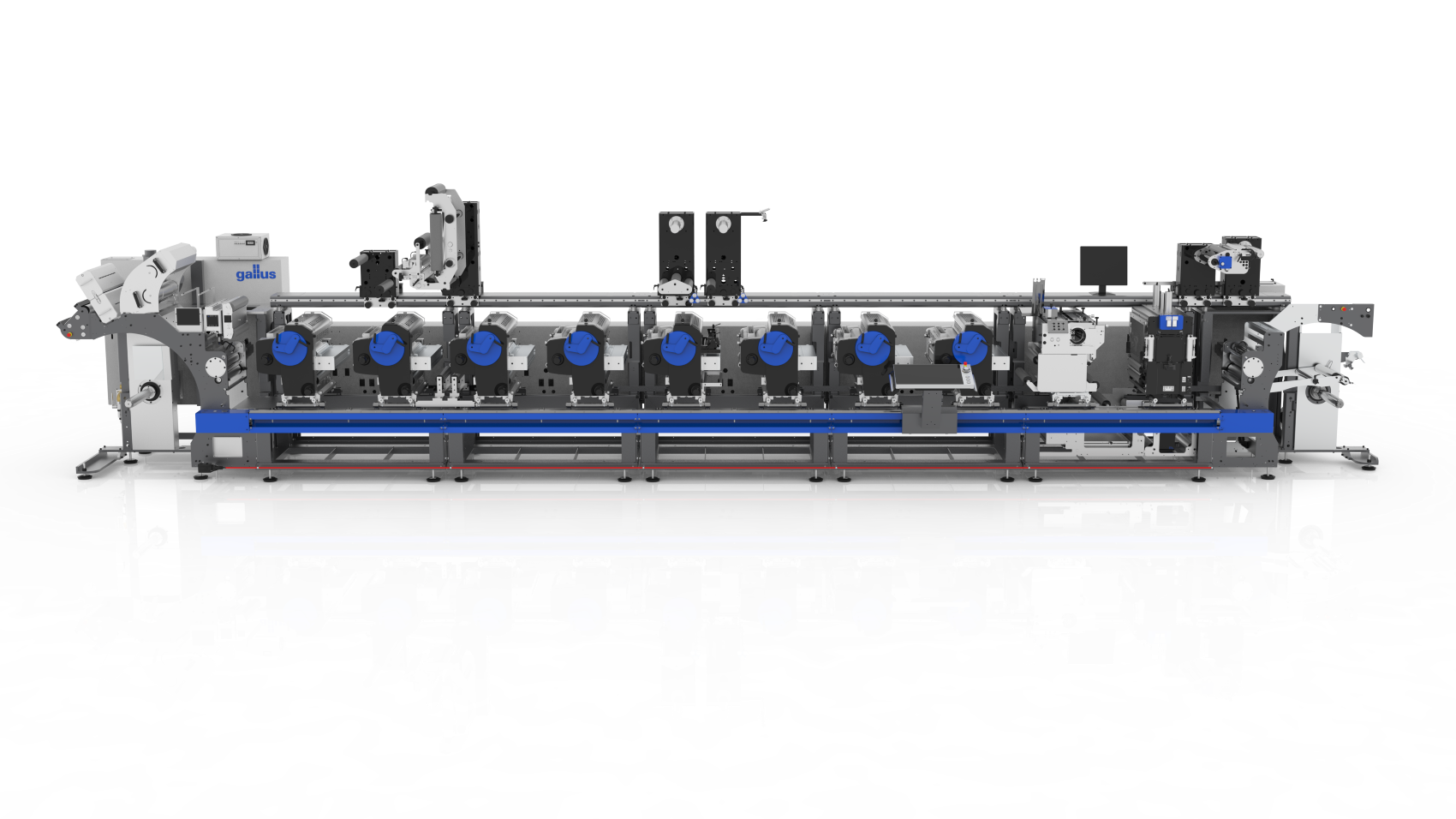

Gallus Labelmaster Advanced line

Process variability at every position and a high degree of automation offer maximum flexibility. This is because the printing process can be changed at any position.

Despite its extensive modules and the resulting flexibility, the Gallus Labelmaster impresses with its intuitive and simple operation with automated presetting functions. This means that all product lines can be operated without any problems after a very short training period. From the quick and easy replacement of the lightweight aluminum printing cylinders to comprehensive operation, whether via the clear HMITouchpanel or directly on the printing unit, the focus is clearly on simplicity, speed, and safety. At Gallus, we call this Best-Spot-Interaction!

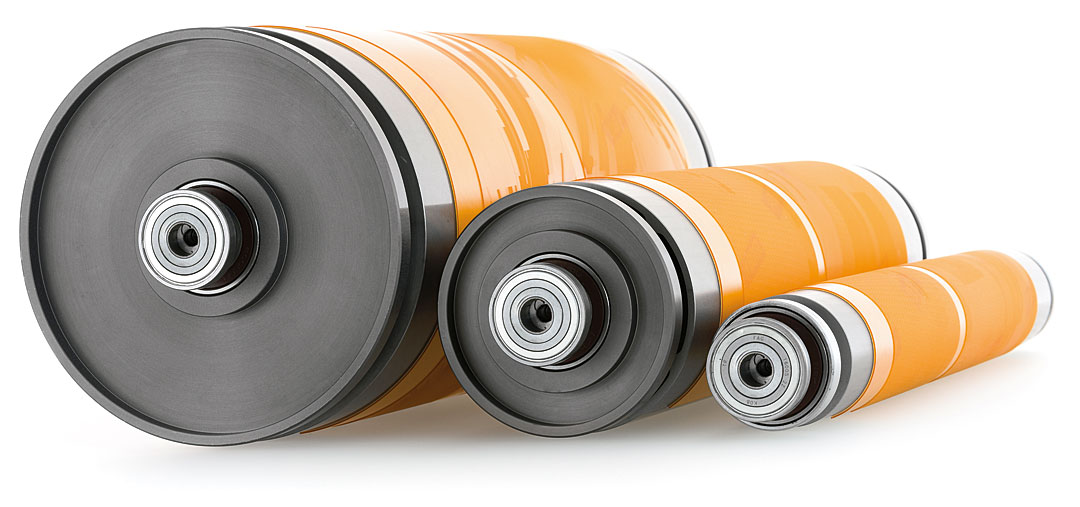

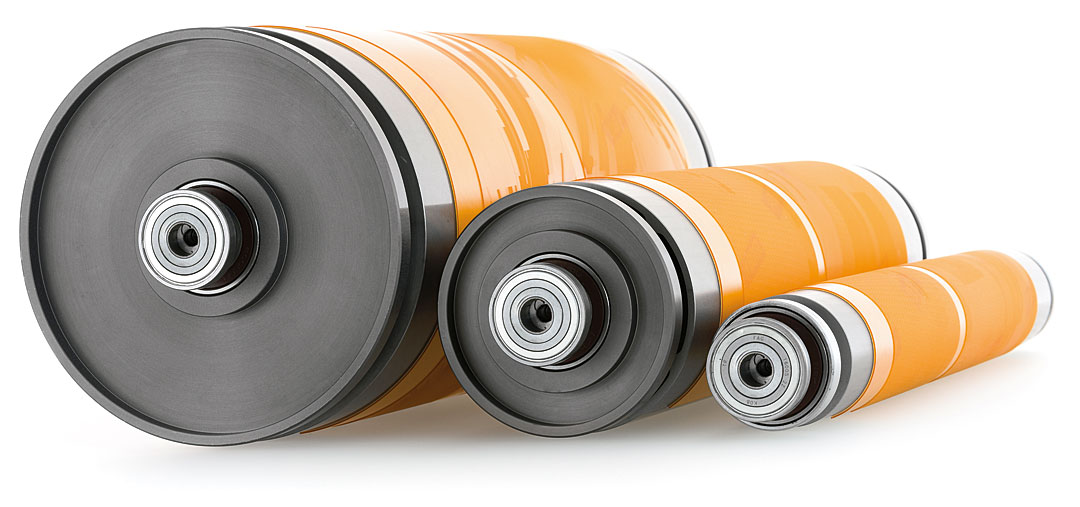

Exceptionally short setup times and super-fast job changes thanks to gearless, lightweight printing cylinders.

The Gallus Labelmaster impresses not only with its flexibility, but also during operation. This new machine platform can handle even high printing speeds of up to 200 m/min with absolute register accuracy. An optimized ink chamber ensures perfect ink transfer to the anilox rollers at all times, with low splashing and reduced foaming.

With the Gallus Labelmaster printing press platform, Gallus has also developed a locking system that enables quick, easy, and precise changing of the printing units*. These are positioned precisely on the base unit via the system and guarantee 100% register accuracy across a wide range of substrates.

Whether during slow start-up or when accelerating to a top speed of up to 200 m/min, the print image of the Gallus Labelmaster remains perfectly in register, underlining the unique quality and precision of the new machine platform. Time-consuming post-corrections are not necessary.

The Gallus Labelmaster also sets new economic standards. From massive time savings thanks to its simple operation and fast printing speed to low waste rates and minimal material consumption. The Gallus Labelmaster impresses from the very first print and makes label printing easier, faster, and more profitable!

The Gallus Labelmaster offers a wide range of print cylinder sizes between 8" and 25".

| 340 | 440 | 570 | |

| Machine speed, mechanical, max. | 200 m/min. 656 ft/min. | 200 m/min. 656 ft/min. | 200 m/min. 656 ft/min. |

| Maximum track width | 345 mm 13.4" | 445 mm 17.5" | 575 mm 22.6" |

| Track width min. | 170 mm 6.7" | 220 mm 8.7" | 285 mm 11.2" |

| 340 | 440 | 570 | |

| Maximum print width | 340 mm 13.4" | 440 mm 17.3" | 570 mm 22.4 |

| Maximum format length | 635 mm 25" | 635 mm 25" | 635 mm 25 |

| Minimum format length | 203.2 mm* 8" | 203.2 mm* 8" | 203.2 mm* 8" |

| Minimum format length with optional grid roller servo drive | 254 mm 10" | ||

| Format length min. Screen printing | 269.9 mm 10 5/8" | 269.9 mm 10 5/8" | 269.9 mm 10 5/8" |

| Maximum number of printing operations | 14 | 14 | 14 |

| 340 | 440 | 570 | |

| UV | yes | yes | yes |

| Hot air drying (final drying) | yes | yes | yes |

| 340 | 440 | 570 | |

| Maximum track width | 340 mm 13.4" | 440 mm 17.3" | 570 mm 22.4" |

| Maximum format length | 635 mm 25" | 635 mm 25" | 635 mm 25" |

| Minimum format length | 254 mm 10" | 254 mm 10" | 381 mm 15" |

| Maximum number of processing operations | 6 | 6 | 6 |

| Maximum number of process positions | 16 | 16 | 16 |

| 340 | 440 | 570 | |

| Adhesive composites | yes | yes | yes |

| paper | yes | yes | yes |

| Cardboard | yes | yes | yes |

| Monofoil label materials | yes | yes | yes |

| Tube laminates | yes | yes | yes |

| 340 | 440 | 570 | |

| Gallus Remote Access | yes | yes | yes |

| All technical specifications are approximate values. We reserve the right to make technical changes. |

| * Sieve from 10 5/8 " |