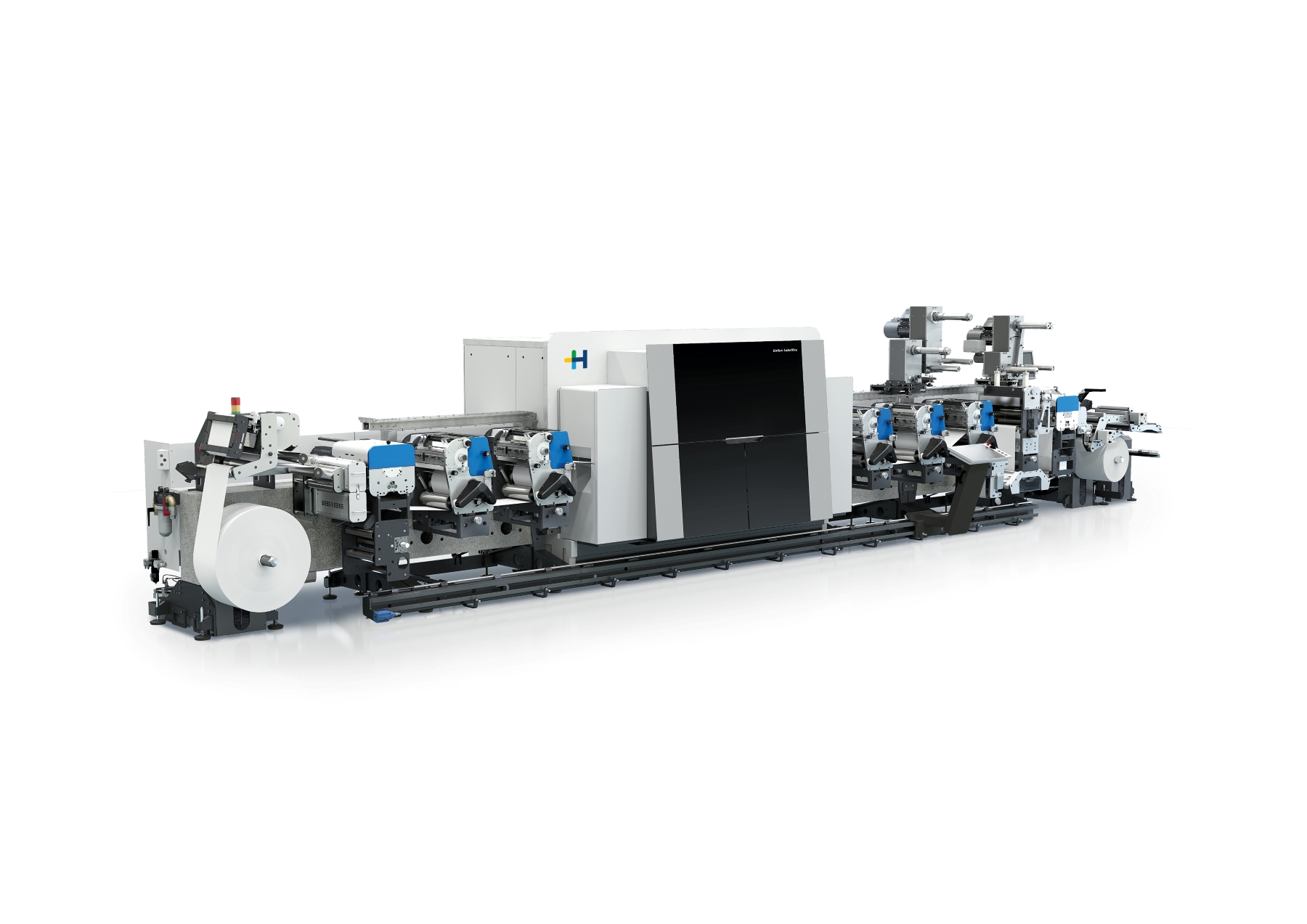

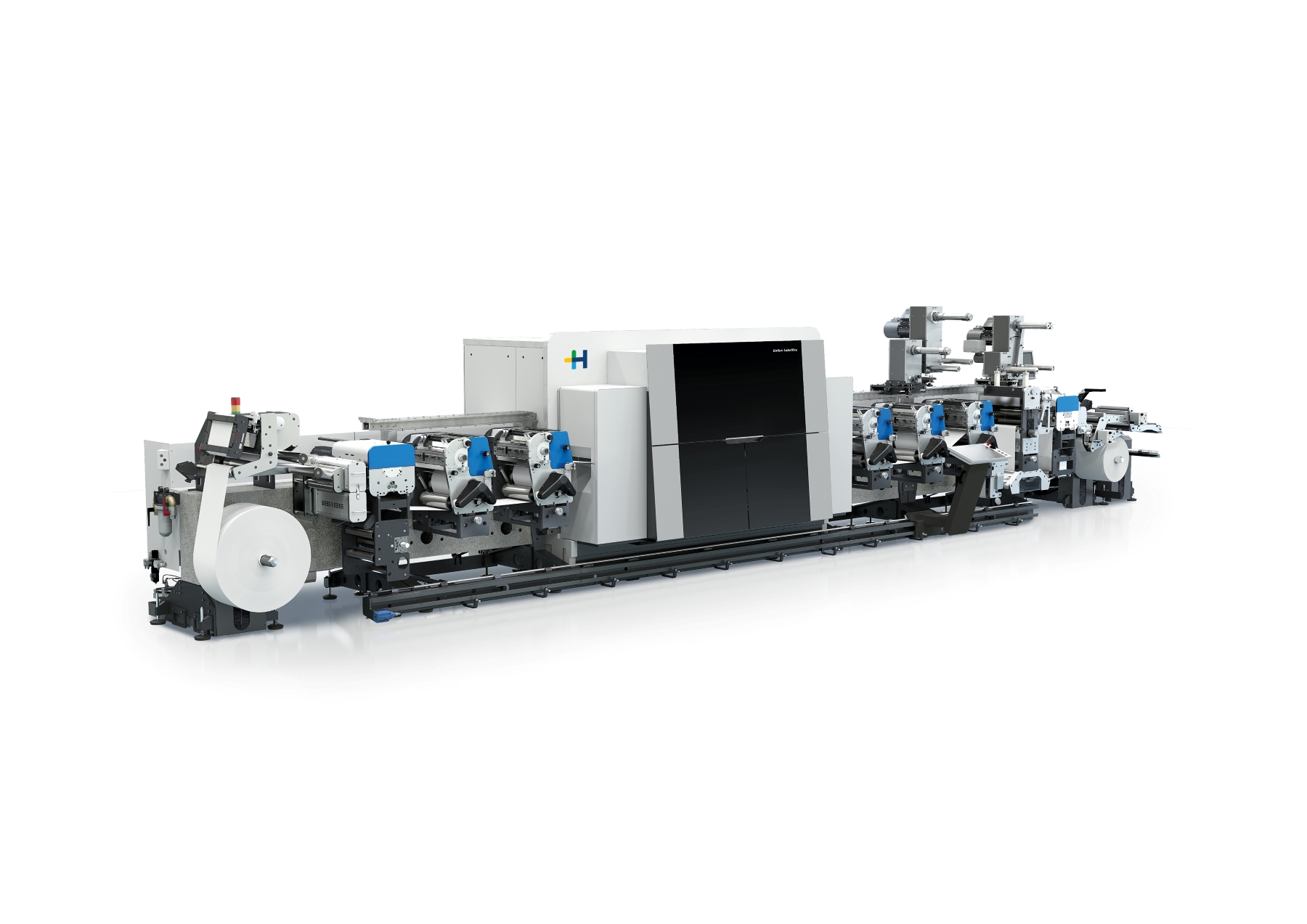

The innovative digital printing system has been successfully on the market since 2015 and combines the best of both worlds: the flexibility and versatility of digital printing with the reliability and precision of conventional printing and finishing technology. Printing, coating, finishing, and converting labels on the Gallus Labelfire inline – from roll to finished label in a single production run.

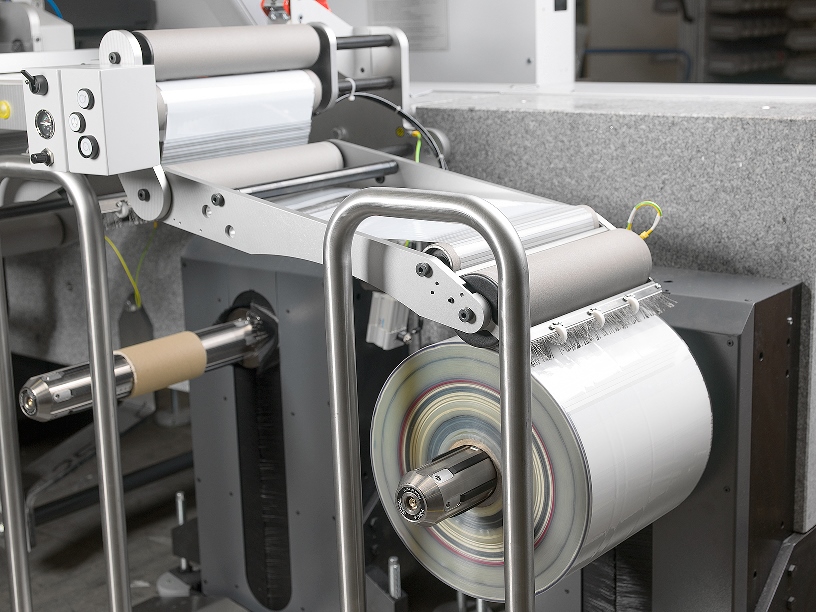

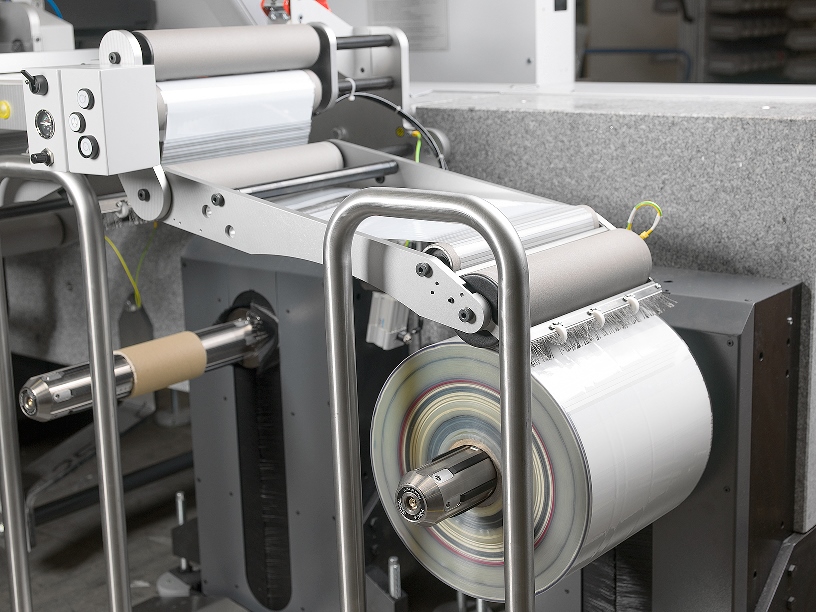

At the same time, the conventional printing functions of the Gallus Labelfire offer additional options for finishing and inline processing, such as coating, laminating, and die-cutting. A fair, consumption-based business model ensures that ink prices and services are in line with market requirements and that customers benefit directly from the process optimizations they achieve.

The digital flexibility of the Gallus Labelfire printing unit is optimally supported by the integrated Gallus ECS modules. The strengths of digital printing combined with those of the digitally optimized inline finishing processes of a conventional label printing press open up completely new possibilities: labels can be coated, laminated, finished with cold foil, and further processed with a die cutter in a single operation.

The conventional modules enable the use of primer, spot colors, security or cold foil elements, varnish or lamination without interrupting production – regardless of the complexity of the label.

As an industrial production system, the Gallus Labelfire excels in small and medium-volume production and beyond. From the substrate to the finished label roll, only a single operation is required – production or machine stops for finishing and further processing are avoided.

The Gallus Labelfire is a system with consistent operating logic that integrates digital printing, conventional printing, and finishing. The label is produced inline in a single production run – from the unprinted roll to the weed-free end product. One of the key strengths of the Gallus Labelfire machine system is its high flexibility. The digital printing unit even enables cost-effective production of runs with variable data, versioning, and short runs.

For over 90 years, Gallus has stood for "success and reliability for label printers." Together with Heidelberg, whose decades of experience in digital prepress and solid printing press engineering, the unique industrial inkjet production system was optimally developed—the Gallus Labelfire.

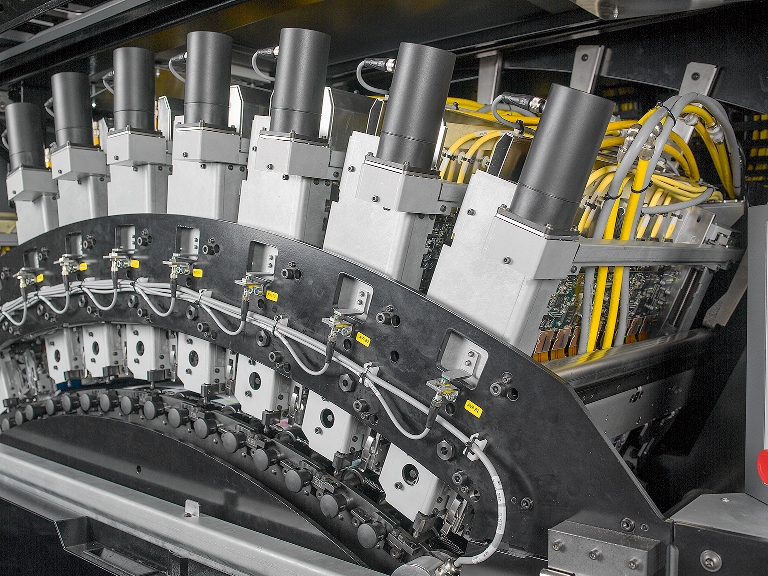

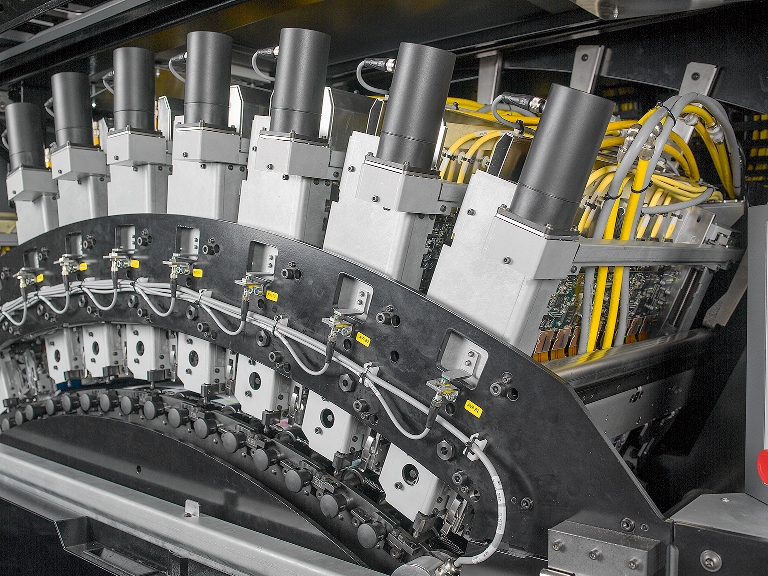

The 4- or 8-color inkjet system covers up to 94 percent of the simulated PANTONE® PLUS color gamut* in top quality. All machine configurations offer a native resolution of 1200 x 1200 dpi for maximum print quality at speeds of up to 70 m/min.

With the Gallus Labelfire digital production system, label printers can achieve print quality that matches high-resolution offset printing. This is evident in the native (physical) resolution of 1,200 × 1,200 dpi with a droplet size of only 2 pl and four different droplet sizes. This results in a visual resolution of 2,400 × 2,400 dpi.

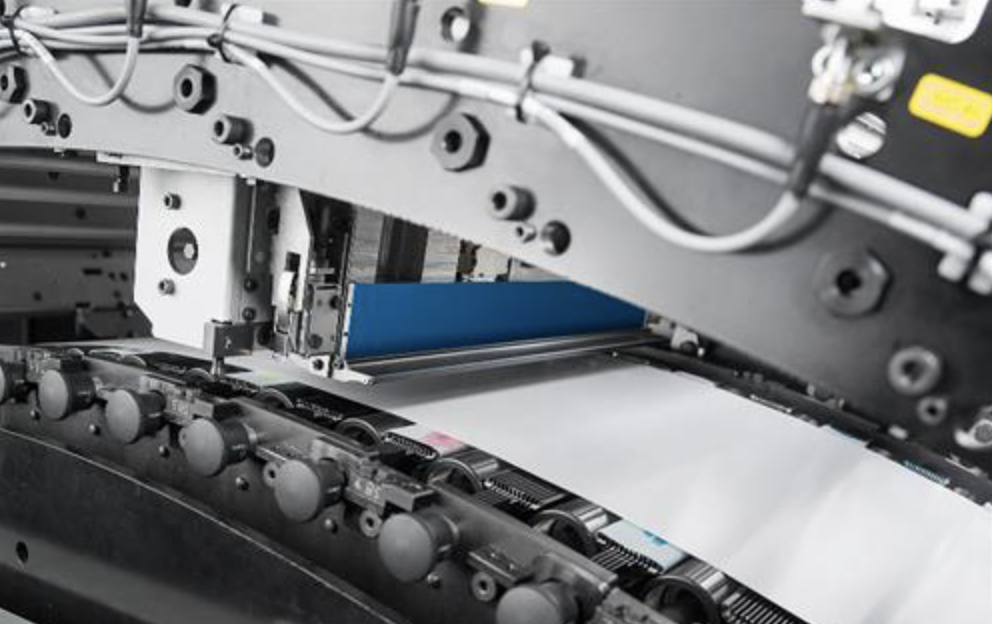

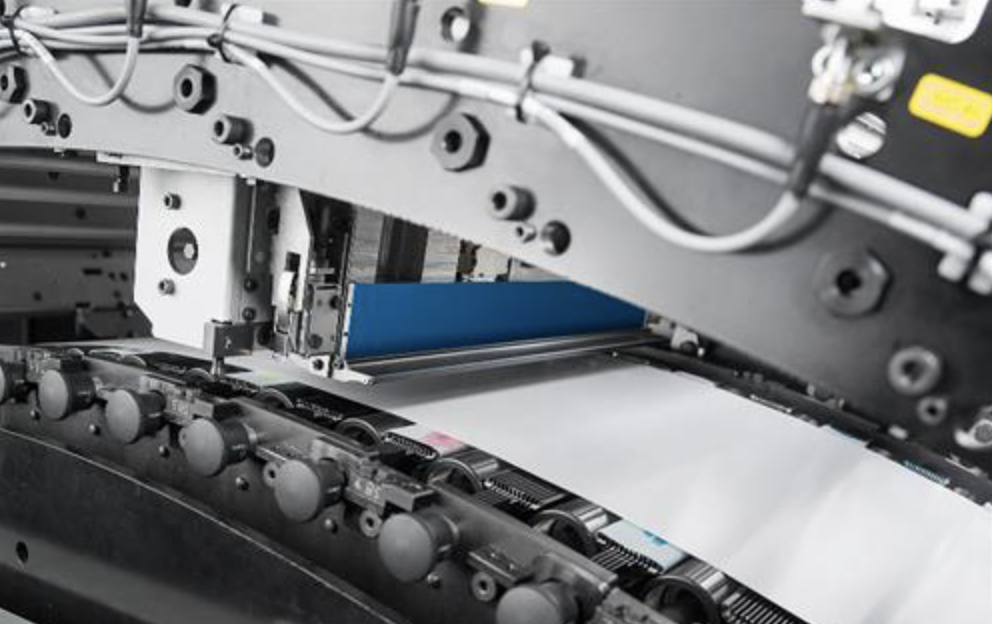

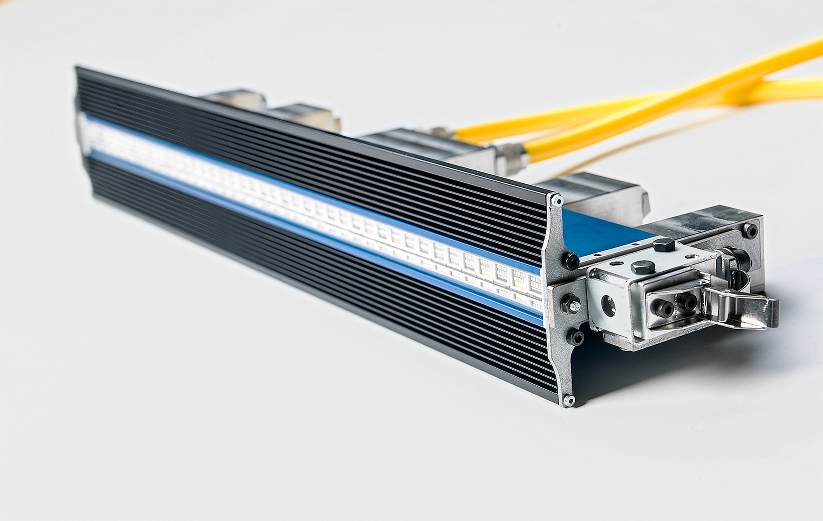

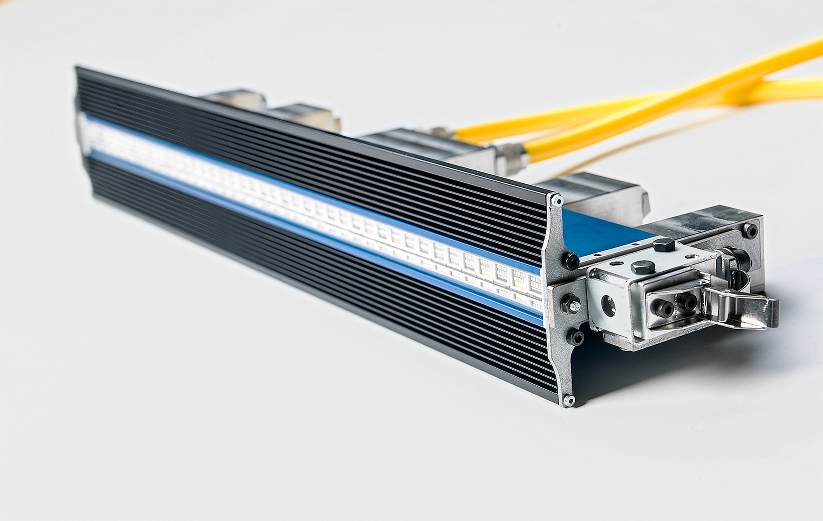

Only the high physical resolution allows small characters and letters as well as fine lines and color gradients to be printed with zero percent coverage. The smallest droplet size currently available in the printing industry results in smooth, silk-matt surfaces, better ink adhesion and curing, and reduced ink consumption. The unique inkjet printhead design allows for inkjet head mounting with seamless transitions. This results in consistent print quality across the entire web width.

By combining digital white, CMYK, the color space extension colors orange, violet, and green, and 7-color separation, the Gallus Labelfire 340 machine system can cover a large portion of the simulated PANTONE® PLUS color scale. All this is made possible by the use of specially developed screening and color management algorithms, which HEIDELBERG has been using successfully in its offset prepress solutions for decades.

The compact, digital production system combines state-of-the-art UV inkjet print quality and highly efficient digital printing with the inline productivity and speed of flexographic printing and the advantages of screen printing. This is made possible by drop-on-demand inkjet technology in combination with conventional finishing units that have been tried and tested thousands of times and full integration into the Prinect workflow.

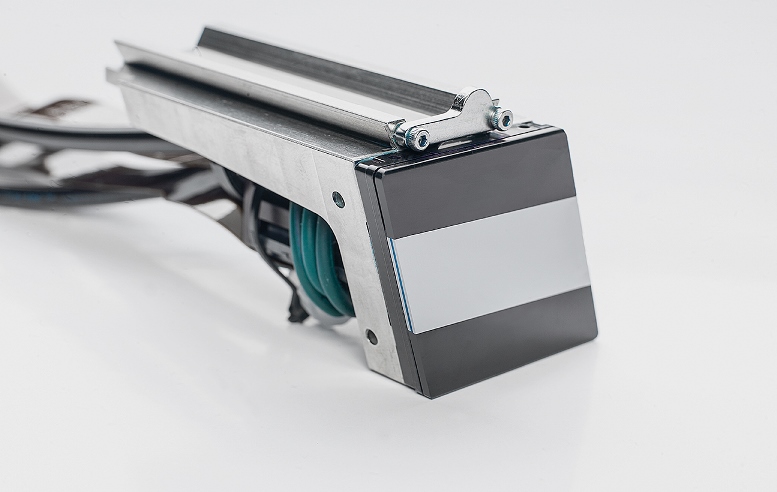

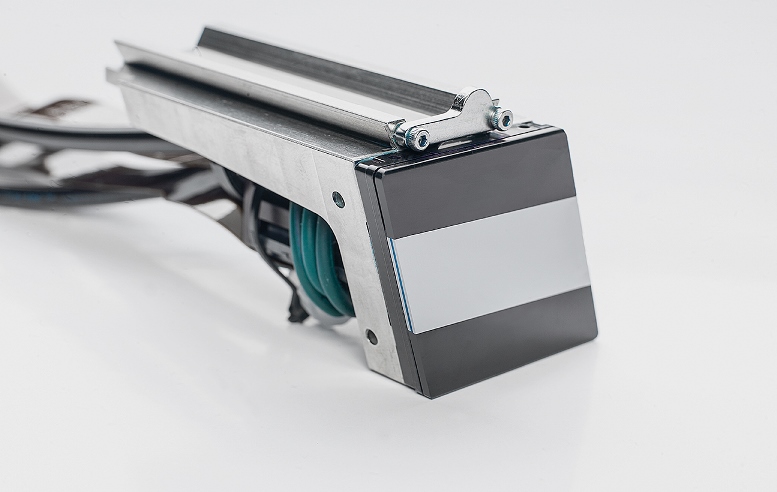

The Gallus Labelfire combines the superior, highly innovative Fuji Film UV drop-on-demand inkjet technology with the proven Gallus ECS 340 modules, which serve as the base machine. In addition, the digital machine system features inkjet print heads that have a service life of several years in two or even three shifts. Automated maintenance and cleaning cycles support high system reliability and availability.

In addition, the Gallus Labelfire features a proprietary process for detecting and compensating for malfunctioning nozzles in the inkjet print heads. Thanks to the interaction of camera detection in the digital printing unit and specially developed algorithms, so-called "white lines" and "dark lines" and even the "ghosting" phenomenon are now a thing of the past.

The Gallus Labelfire is delivered as a complete, production-ready solution—software and hardware are included. Prinect, Heidelberg's workflow software, is used for the digital front end (DFE). The DFE is an indispensable, integral part of the digital printing system. It allows the printer to concentrate fully on production on the press, while the data is prepared in optimum quality for printing in the prepress stage.

The Gallus HMI touchscreen control panel takes over the data after it has been prepared in the prepress stage at the touch of a button when the job changes. Your benefits: simple, intuitive operation and control of the modules using the same control unit as for the digital unit.

The unique inkjet printhead design enables seamless head mounting, resulting in consistent, streak-free print quality across the entire web width.

The Gallus Labelfire's digital front end impresses with its practical functions, including spot color matching, PDF toolbox, and prepress manager. All available conventional printing functions meet the requirements of efficient short-run production thanks to optimized makeready times, minimized waste, and tooling costs. The double rewinders also enable quick changeovers and interlaced winding of narrow small rolls, while reducing makeready times.

Highest productivity combined with low ink prices and efficient color management from Prinect enable printers to produce labels with an excellent price-performance ratio.

The best available resolution of 1200 × 1200 dpi (native) at 70 m/min* and camera-based quality assurance ensure perfect print quality. The single color pinning process ensures the sharpest print results, even with extra-fine lines and very small fonts. The 7-color printing unit is capable of simulating up to 94%** of PANTONE® PLUS colors. Consistent color stability throughout the entire production run of the machine guarantees exact reproducibility of print jobs in subsequent print runs.

One control panel for everything. The integrated register control and Human Machine Interface (HMI) of the Gallus Labelfire ensure simple and intuitive operation. The conventional modules are controlled using the same operating logic as the digital printing unit. In addition, camera-based quality monitoring and nozzle fault detection and compensation ensure maximum inkjet print quality.

| Printing process | UV - Piezo DoD - InkJet |

| Print speed | up to 70 m/min |

| Productivity | Max. printing area 1428 m²/h |

| Print resolution | 1200x1200 dpi native @2pl droplet size Optical resolution approx. 2400 x 2400 dpi, > 200 grayscale levels |

| Number of digital print modules Gallus LabelFire 34 | Various versions available

|

| Colors Gallus LabelFire 340 | 4 to 8colors Depending on the configuration: CMYK + GOV (green/orange/violet) + digital white, CMYK + GOV, CYMK + digital white, CYMK) |

| Maximum print width | 340 mm |

| Substrates | Monofilms, papers, and composite materials 50 - 350 µm |

| Special substrates | Cardboard, tube laminates, and thin films 20 - 450 µm |

| Dimensions (L x W x H) | 11,500 x 4,500 x 2,200 mm (basic configuration) |

| Variable data | iVDP (industrial variable data processing, such as barcodes, QR codes, alphanumeric text, etc.) Full variable data printing (optional): for unique applications |

| Interfaces | for common pre-press software solutions |

| Low migration | Swiss Ordinance, Nestlé Guidance, Eupia, GMP |

| Wheel diameter | max. 40" (1016 mm) |

| Number of conventional process platforms | 5 + punching |

| Format length flexo unit | 254 - 508 mm |

| Substrate conditioning | Track cleaning (direct contact + contactless), corona treatment, antistatic treatment and primer (if necessary), flexographic printing (full and spot colors), delamination and relamination, reverse printing |

| Inline processing | Flexographic printing, screen printing, varnishing, cold foiling, laminating, die cutting, grid winding, longitudinal cutting, Digital Embellishment Unit (DEU) |

| Punch | Semi-rotary, format length: 152 - 508 mm (6'' - 20'') ; Fully rotary, format length: 152 - 508 mm (6'' - 20'') |

| Connected load | 121 kW (3P + PE) |

| Excitement | 400V / 50Hz |

| Compressed air | 350 l/min; with 7.5 to max. 10 bar, oil- and water-free |

| Exhaust air | Approx. 2670 m3/h; exhaust air temperature max. 50°C / ozone emission during operation approx. 0.8 mg/m3 |

| Conformity | CE, GS (UL on request) |

| Remote diagnosis | Yes |

| All technical specifications are approximate values. We reserve the right to make technical changes. |

The following special versions of the individual Labelfire machine types are available: Substrate extensions for: lightweight cardboard, tube laminate, and thin films (20–450 μm) Printing of fully variable data (FullVDP): full variability per pixel Low migration: Swiss Ordinance, Nestlé Guidance, Eupia, GMP |