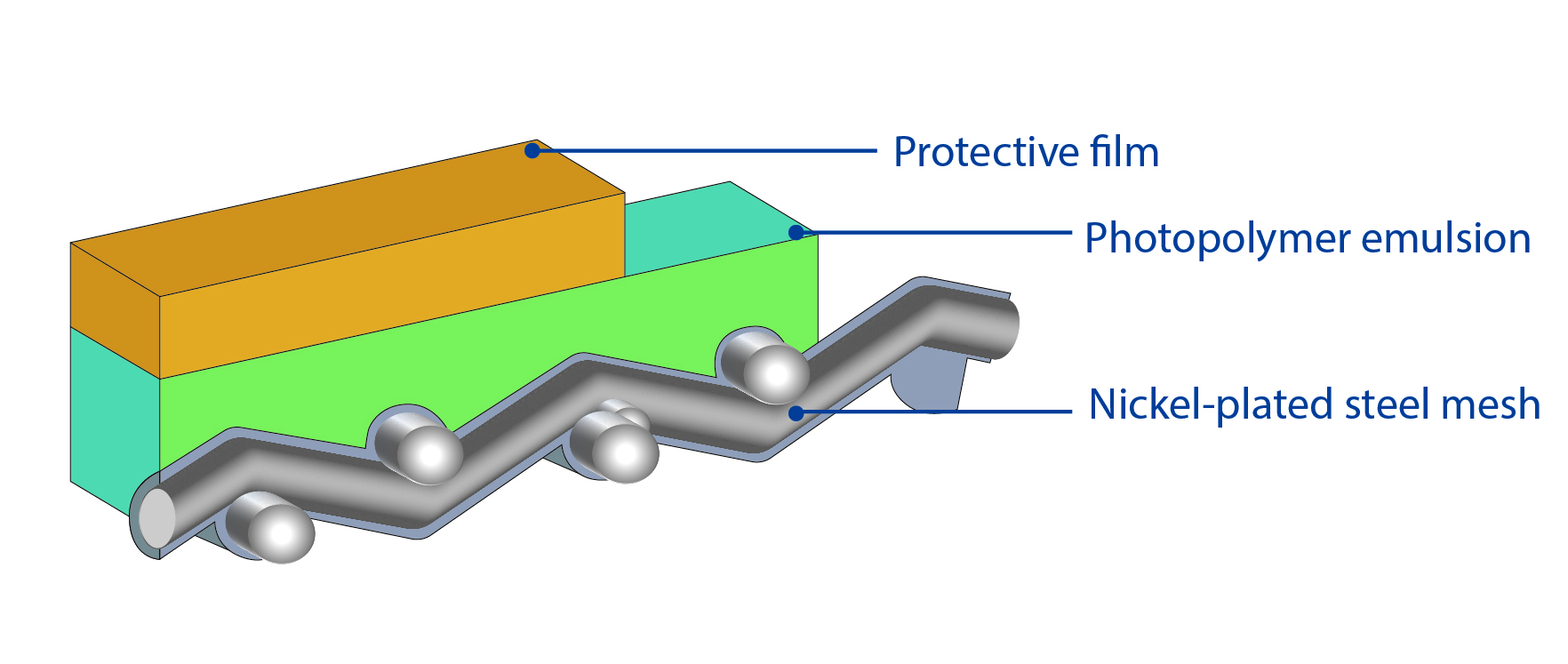

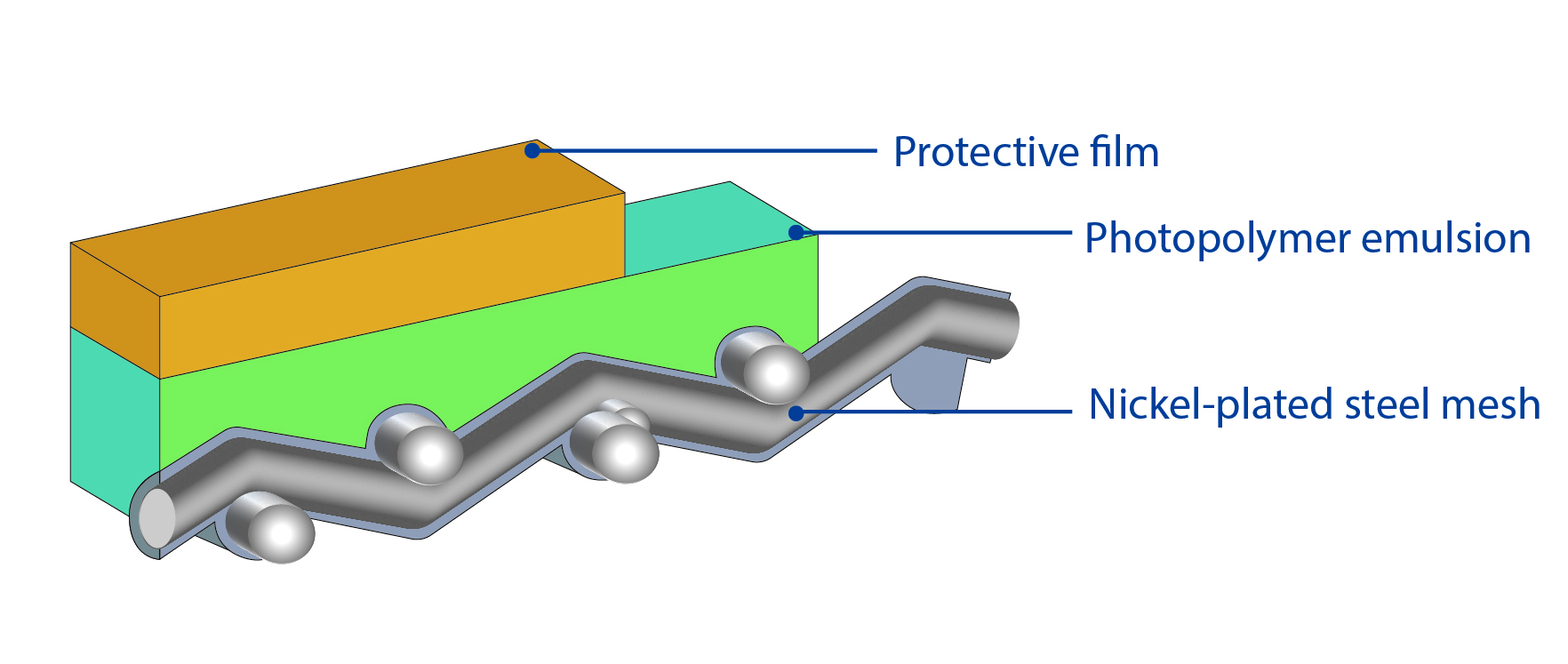

Gallus Screeny® offers a unique complete solution for industrial screen printing on hollow glass. The innovative system combines a production-ready, nickel-plated, and pre-coated screen printing plate with a groundbreaking Fast Tension Frame (FTF) to form a perfectly integrated screen printing system that sets new standards in terms of quality, productivity, reliability, and user-friendliness.

The reusable and customizable Fast Tension Frame guarantees even tension of the Screeny throughout the entire printing process. The intuitive assembly of Screeny® and Fast Tension Frame saves time and money, making this system unmatched in terms of productivity and user-friendliness.