The Sunrise print shop in Saint Petersburg, Russia, launched a Gallus Labelmaster printing press, which is the second press of this model in Russia, in the end of 2017. Therefore, the range of existing equipment in the print shop consists now of four flexo presses, two of them from Gallus, and one digital press. This extending of production capacities was fueled by the company’s business successfully growing since 2001. Sunrise is a label producer serving alcoholic drinks and food industry.

The world premiere of the Gallus Labelmaster platform designed for label or packaging printing took place during the Gallus Innovation Days in September 2016. As the executives at Sunrise claimed, the purchasing of the new press had been a direct consequence of their attending this event. “The Gallus Labelmaster press is the one that fits exactly to our needs”, — Genady Petushkov, Director of Marketing & Sales at Sunrise, said. — “The new press launched in December 2017 fully met our expectations when it came to long runs. It also needs to be noted that the Heidelberg-CIS worked with great deal of attentiveness to every detail in the process of starting-up and adjusting the equipment. There was no any difficulty for our operators when learning to cope with our new Labelmaster”.

The right press for big jobs

The first job that boosted company’s growth involved printing stickers attached to the bubble-gum wrappings. In the early 2000’s, the international manufacturer Wrigley was looking for a local label printer who could be a supplier for their plant launched in Saint Petersburg. The Sunrise print shop rose to the challenge and succeeded to gain the necessary certification to the international standards, having passed all the steps. Then, collaboration started with the Exxon Mobile that was supplying BOPP-films to the labels and packaging markets. The Sunrise production site was then used as a facility for testing the films. All the efforts were repaid later by winning a new special customer — Tinkoff brewery. For its Zooom beer, Sunrise produced for some years a then unique label that was printed on a transparent non-self-adhesive Exxon Mobile film. Designed like no other, the label won the gold medal of the OPPack Award and helped much for the success of the Zooom product.

Today, Sunrise is supplying its products to customers all over Russia and in foreign countries as well. The export is serving the needs of the Ladoga Group, another major player on the FMCG market in Russia. Producing alcoholic drinks, the Group possesses production sites throughout the world. For some of these sites, labels are printed exclusively at the Sunrise not only because of a long-standing partnership but also for economic reasons.

The Ladoga Group is an established customer of the Sunrise print shop that supplies label products to it for its facilities in Russia and foreign countries.

The Ladoga Group is an established customer of the Sunrise print shop that supplies label products to it for its facilities in Russia and foreign countries.

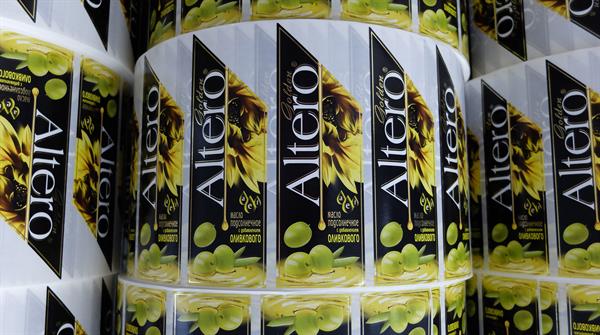

Sunrise has also established a long-term contract with the agri-industrial company Efco, the owner of the Altero and Sloboda vegetable oil brands famous in Russia. The partnership came about after Sunrise managed to offer better terms for the contract. Now the print shop provides labels for the Altero oil and the Efco sour-milk products.

As the experts are saying at the Sunrise, major customers continually bring out new products to the market, which require innovative design and sometimes an elaborate technical solution. Therefore, there is always a need for further improvements to the production process. The head staff is confident that the Gallus equipment is capable to meet any possible challenge. Particularly, the new Gallus Labelmaster has no rivals when it comes to the price-quality ratio. Featuring more stable and precise register control in comparison to the other presses in the print shop, the Labelmaster can also make profits by printing label jobs two or even three times faster. Because of this, almost all long runs in the print shop are now printed on the Labelmaster.

Ashot Akopov, Head of Narrow Web Department at the Heidelberg-CIS, is very happy with a great new step in the longstanding partnership between the Heidelberg-CIS and Sunrise. “We really highly appreciate your positive approach to analyzing the offering on the market. Thank you very much for having chosen the Labelmaster. Almost 20 years have passed since our companies came to know each other — as from the time of the installation of the Gallus Arsoma that serves you faithfully up to date. After the Labelmaster came on, we managed to offer a suitable press that is capable to extend the existing range of equipment at the print shop and reinforce the productive capacities. The complete Gallus portfolio gives us the flexibility to deliver the right press to any customer, whatever the requirements are.”

Sunrise produces labels for the Altero vegetable oil brand and sour milk products of the agri-industrial company Efco.

Sunrise produces labels for the Altero vegetable oil brand and sour milk products of the agri-industrial company Efco.

The Gallus Labelmaster press is made up of separate modules. On each of them two printing units can be mounted. The modules are available in three different variants. The Basic version already meets all the requirements of the label printing process. The Plus version provides greater flexibility; the Advanced version offers the most extensive possibilities regarding configuring and automation to meet almost any need of the customer.

Hot on the heels of the successful debut of the Gallus Labelmaster during the Gallus Innovation Days in September 2016, Gallus presented the Labelmaster Advanced version with multiweb feature at Labelexpo 2017 in Brussels. The Gallus Labelmaster Advanced line’s impressive modular design combines maximum flexibility with a high level of automation. The new press offers label printers an unrivalled variety of processes, as the various finishing and printing units can be changed quickly and easily at any machine position.

The new Gallus Labelmaster platform builds on the successful, tried-and-tested design principle of Speedmaster offset printing presses from Heidelberg.