27.07.2020

Many of the macro trends (1) recently identified in label and packaging printing are having an impact on product design for labels and packaging – and thus on the requirements that machines such as the Gallus Labelmaster must meet today. The following overview of current developments and trends specifies these requirements in more detail.

Changes in consumer behavior and trends that can be attributed to fashion and design or developments in the retail sector are at the forefront of macro trends. For label and packaging printing, this is reflected in an increase in order changes and declining print runs.

Exceptionally short setup times and super-fast job changes thanks to gearless, lightweight printing cylinders (image source: Gallus Ferd. Rüesch AG)

Consumers are becoming increasingly conscious and want to know what is contained in a package, which leads to more information and therefore more text on labels and packaging. This is further reinforced by language diversity and mandatory information for products that require explanation, such as pharmaceuticals. These developments are creating a positive trend for booklet labels, but also for smaller print runs, as information can change quickly.

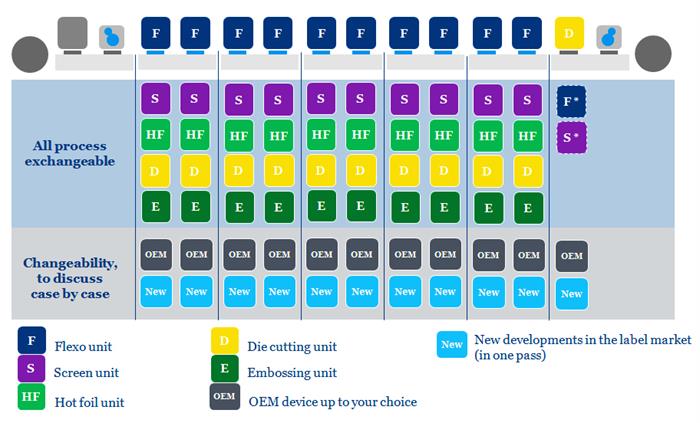

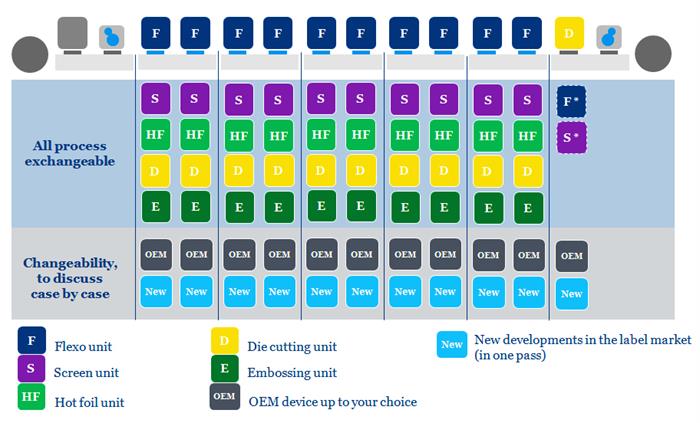

With the Gallus Labelmaster Advanced, all flexographic printing units can be replaced with screen printing units, hot foil units, or die-cutting units. Replacement with units from OEM manufacturers is also possible (image source: Gallus Ferd. Rüesch AG).

The current trend in consumer behavior toward simplicity in design does not necessarily mean that this also means less effort in terms of printing.

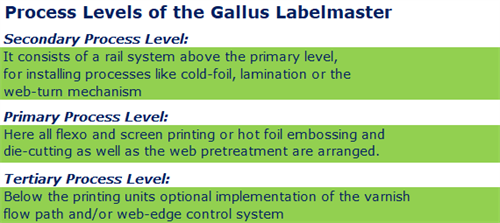

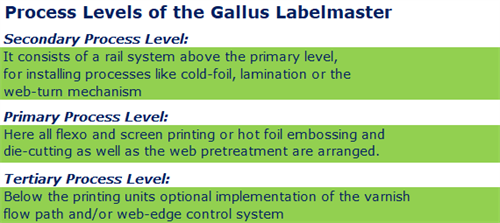

What technical features do modern machine systems need to have today to meet these market requirements? The Gallus Labelmaster belongs to a class of machines that offers a balanced level of automation and high cost-effectiveness for the operator. With its modular design, it offers a wide range of configuration options and is therefore perfectly in line with market requirements: The Gallus Labelmaster Advanced is designed so that all process changes in the printing section take place on one level, known as the primary process level. This means that all flexographic printing units can be replaced by screen printing units, hot foil units, or die-cutting units. Replacement with units from OEM manufacturers is also possible.

With this configuration, changing the printing process, i.e. switching from one printing unit to another, takes less than 15 minutes until the press is ready to print. This makes the machine system flexible and configurable for any job situation.

The Gallus Labelmaster Advanced does not need to be switched off during process changes; the process change takes place while the machine is running, which saves time and money. Since all units are located on the same guide axis, this also offers control advantages over machine systems in which the screen printing unit is located on a rail above the flexographic printing units or is added as a drop-in station.

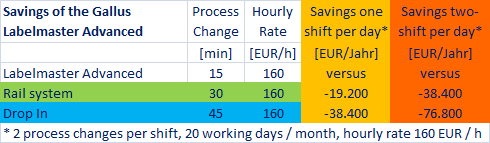

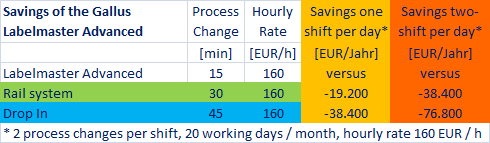

Although these machines also offer a certain degree of flexibility, there are significant losses in changeover times, print stability and, ultimately, in the productivity of the machine solution. Process changes take significantly longer with such solutions, approx. 30 minutes (+100 percent) for rail systems and up to 45 minutes (+200 percent) for drop-in variants. Assuming approximately two process changes per shift in practice, this difference in the time required for process changes translates into annual savings of EUR 38,400 in a two-shift operation compared to a rail system, or EUR 76,800 compared to a drop-in variant. In line with macro trends, process changes will continue to increase and, in the future, short process changes will become even more important for the efficiency of a machine system.

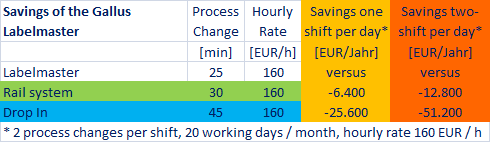

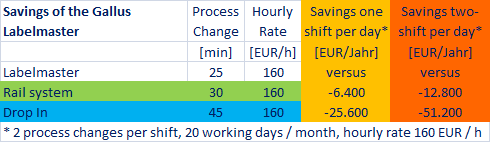

Even the basic version of the Gallus Labelmaster offers the option of two interchangeable processes within the printing section, for example, a screen printing unit and hot foil stamping instead of two flexographic printing units. Here, too, the change can be made at any position on the machine. Machines that were configured as pure flexographic printing lines at the time of purchase can be retrofitted to allow two units to be exchanged, for example with a die cutter or a screen printing unit. This allows customers to use the machine for other applications/products and ensures investment security in the event of a changing product portfolio. If a cost comparison for process changes with machine systems of a different design is made for this machine variant, the result is an annual saving of EUR 12,800 compared to a rail system, or EUR 51,200 compared to a drop-in variant.

Today's machine systems must also cater to other trends. One of these trends is sustainability in packaging, which will become much more important in the future.

Following these trends, the question arises as to how a machine concept must be designed to meet the requirements of ecology and sustainability. A low waste ratio is not only an important criterion for sustainability reasons, but also means potential savings. With the Gallus Labelmaster, the web travel from printing unit to printing unit is 1.4 m. This is made possible by arranging all essential processes on the primary level, eliminating the need to switch to another level. The use of a screen printing unit on a rail, for example, causes an additional web path of 4 to 6 m. The arrangement of the printing units on the primary level, on the other hand, saves material, time, and costs during setup and becomes even more important as order and material changes increase.

The user-friendly features of a printing press are also crucial for fast process and job changes. This includes all of the "easy-to-use" features. For example, no chain pull is required when changing processes at the primary process level. Or stable printing units in which the impression cylinders and anilox rollers are equipped with Schmitz rings. These ensure consistent print quality by preventing the formation of tooth marks, which always occur over time with gear-driven impression cylinders. The lightweight impression cylinders on the Gallus Labelmaster can be changed in a very short time. For a machine with eight printing units, the changeover takes less than 8 minutes, and even less if two employees work simultaneously. A special clamping system has been developed to hold the cylinders in place. Another advantage is the practical and ergonomic arrangement of the control buttons, which are located where the operator expects them to be based on experience.

The printing units can be easily removed for maintenance, so there is no machine downtime during servicing. When screen printing units are integrated, it is advantageous that they are designed and manufactured by Gallus itself and that a separate model is used for each machine type, which is integrated into the control system. Also worth mentioning is the design of the chamber doctor blades, with robust ink chambers that require a very low ink quantity of 220 to 1,500 ml. The rounded shape of the ink channel in the chamber doctor blade improves ink circulation with less tendency for air pockets and allows for easier cleaning. All these criteria contribute to a machine that is easy for the operator to use and can be quickly converted.

With its concept for unrestricted flexibility in process and job changes at the primary process level, the Gallus Labelmaster perfectly meets the requirements of today's macro trends in label and packaging printing. Fast job and process changes are becoming increasingly important in order to remain competitive and produce efficiently. At the same time, a flexible machine concept means investment security for the user, as it can be quickly adapted to changing market conditions. This makes it worthwhile for print shops to calculate the costs of everyday production on a label printing machine – over the entire life cycle of the respective machine solution. In the wake of increasing industrialization in label and packaging printing, the productivity of the machine solution is becoming the key driver for sustainable business success.

27.07.2020

Many of the macro trends (1) recently identified in label and packaging printing are having an impact on product design for labels and packaging – and thus on the requirements that machines such as the Gallus Labelmaster must meet today. The following overview of current developments and trends specifies these requirements in more detail.

Changes in consumer behavior and trends that can be attributed to fashion and design or developments in the retail sector are at the forefront of macro trends. For label and packaging printing, this is reflected in an increase in order changes and declining print runs.

Exceptionally short setup times and super-fast job changes thanks to gearless, lightweight printing cylinders (image source: Gallus Ferd. Rüesch AG)

Consumers are becoming increasingly conscious and want to know what is contained in a package, which leads to more information and therefore more text on labels and packaging. This is further reinforced by language diversity and mandatory information for products that require explanation, such as pharmaceuticals. These developments are creating a positive trend for booklet labels, but also for smaller print runs, as information can change quickly.

With the Gallus Labelmaster Advanced, all flexographic printing units can be replaced with screen printing units, hot foil units, or die-cutting units. Replacement with units from OEM manufacturers is also possible (image source: Gallus Ferd. Rüesch AG).

The current trend in consumer behavior toward simplicity in design does not necessarily mean that this also means less effort in terms of printing.

What technical features do modern machine systems need to have today to meet these market requirements? The Gallus Labelmaster belongs to a class of machines that offers a balanced level of automation and high cost-effectiveness for the operator. With its modular design, it offers a wide range of configuration options and is therefore perfectly in line with market requirements: The Gallus Labelmaster Advanced is designed so that all process changes in the printing section take place on one level, known as the primary process level. This means that all flexographic printing units can be replaced by screen printing units, hot foil units, or die-cutting units. Replacement with units from OEM manufacturers is also possible.

With this configuration, changing the printing process, i.e. switching from one printing unit to another, takes less than 15 minutes until the press is ready to print. This makes the machine system flexible and configurable for any job situation.

The Gallus Labelmaster Advanced does not need to be switched off during process changes; the process change takes place while the machine is running, which saves time and money. Since all units are located on the same guide axis, this also offers control advantages over machine systems in which the screen printing unit is located on a rail above the flexographic printing units or is added as a drop-in station.

Although these machines also offer a certain degree of flexibility, there are significant losses in changeover times, print stability and, ultimately, in the productivity of the machine solution. Process changes take significantly longer with such solutions, approx. 30 minutes (+100 percent) for rail systems and up to 45 minutes (+200 percent) for drop-in variants. Assuming approximately two process changes per shift in practice, this difference in the time required for process changes translates into annual savings of EUR 38,400 in a two-shift operation compared to a rail system, or EUR 76,800 compared to a drop-in variant. In line with macro trends, process changes will continue to increase and, in the future, short process changes will become even more important for the efficiency of a machine system.

Even the basic version of the Gallus Labelmaster offers the option of two interchangeable processes within the printing section, for example, a screen printing unit and hot foil stamping instead of two flexographic printing units. Here, too, the change can be made at any position on the machine. Machines that were configured as pure flexographic printing lines at the time of purchase can be retrofitted to allow two units to be exchanged, for example with a die cutter or a screen printing unit. This allows customers to use the machine for other applications/products and ensures investment security in the event of a changing product portfolio. If a cost comparison for process changes with machine systems of a different design is made for this machine variant, the result is an annual saving of EUR 12,800 compared to a rail system, or EUR 51,200 compared to a drop-in variant.

Today's machine systems must also cater to other trends. One of these trends is sustainability in packaging, which will become much more important in the future.

Following these trends, the question arises as to how a machine concept must be designed to meet the requirements of ecology and sustainability. A low waste ratio is not only an important criterion for sustainability reasons, but also means potential savings. With the Gallus Labelmaster, the web travel from printing unit to printing unit is 1.4 m. This is made possible by arranging all essential processes on the primary level, eliminating the need to switch to another level. The use of a screen printing unit on a rail, for example, causes an additional web path of 4 to 6 m. The arrangement of the printing units on the primary level, on the other hand, saves material, time, and costs during setup and becomes even more important as order and material changes increase.

The user-friendly features of a printing press are also crucial for fast process and job changes. This includes all of the "easy-to-use" features. For example, no chain pull is required when changing processes at the primary process level. Or stable printing units in which the impression cylinders and anilox rollers are equipped with Schmitz rings. These ensure consistent print quality by preventing the formation of tooth marks, which always occur over time with gear-driven impression cylinders. The lightweight impression cylinders on the Gallus Labelmaster can be changed in a very short time. For a machine with eight printing units, the changeover takes less than 8 minutes, and even less if two employees work simultaneously. A special clamping system has been developed to hold the cylinders in place. Another advantage is the practical and ergonomic arrangement of the control buttons, which are located where the operator expects them to be based on experience.

The printing units can be easily removed for maintenance, so there is no machine downtime during servicing. When screen printing units are integrated, it is advantageous that they are designed and manufactured by Gallus itself and that a separate model is used for each machine type, which is integrated into the control system. Also worth mentioning is the design of the chamber doctor blades, with robust ink chambers that require a very low ink quantity of 220 to 1,500 ml. The rounded shape of the ink channel in the chamber doctor blade improves ink circulation with less tendency for air pockets and allows for easier cleaning. All these criteria contribute to a machine that is easy for the operator to use and can be quickly converted.

With its concept for unrestricted flexibility in process and job changes at the primary process level, the Gallus Labelmaster perfectly meets the requirements of today's macro trends in label and packaging printing. Fast job and process changes are becoming increasingly important in order to remain competitive and produce efficiently. At the same time, a flexible machine concept means investment security for the user, as it can be quickly adapted to changing market conditions. This makes it worthwhile for print shops to calculate the costs of everyday production on a label printing machine – over the entire life cycle of the respective machine solution. In the wake of increasing industrialization in label and packaging printing, the productivity of the machine solution is becoming the key driver for sustainable business success.