07.03.2016

The flexographic printing plate can be described as the heart of flexographic printing, as it has a decisive influence on the print results and production efficiency of a label printer. There are well over 40 different flexographic printing plates available on the market for label printers, but these can differ fundamentally in terms of their properties, printing behavior, and manufacturing process.

This often presents label printers with the extremely difficult task of selecting a suitable printing plate type. For this reason, Gallus took the time to thoroughly examine and compare the printing characteristics of all well-known flexographic printing plates during a test phase lasting several weeks. The results and evaluations ranged from excellent to unusable. Although there is no such thing as the perfect flexographic printing plate for all applications, a few top flexographic printing plates were identified that are ideal for label printers.

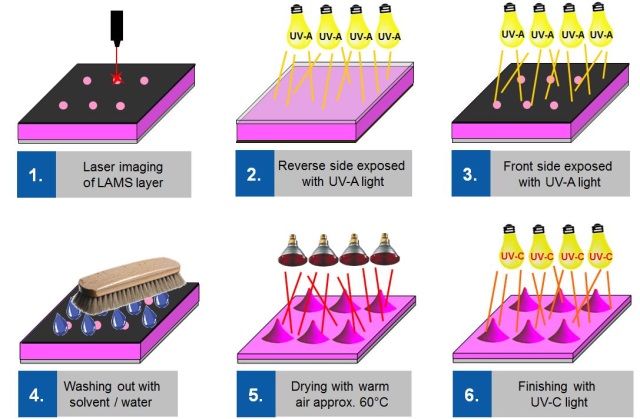

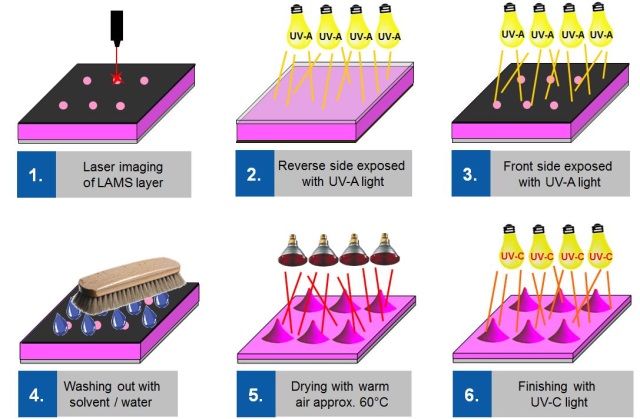

Most flexographic printing plates today are made of photopolymer; rubber plates are much less common. The washout processes for photopolymer printing plates range from the use of solvents to water and thermal development. However, the majority of photopolymer flexographic printing plates are washed out with solvents or water, with the individual steps (1-6) as follows:

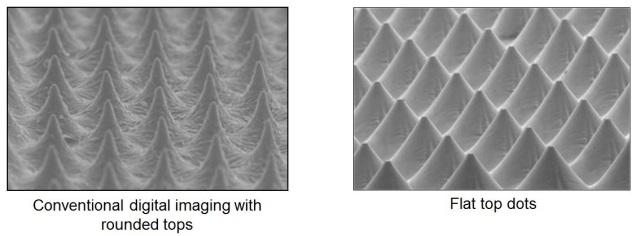

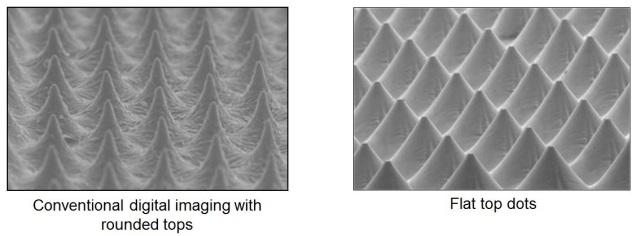

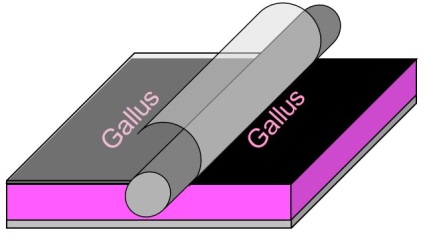

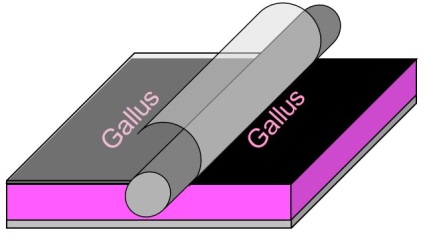

In the printing plate market, there is currently a trend toward flat top dot technology. These printing plates have a printing point that is flat at the tip rather than rounded. This enables more consistent and accurate printing results.

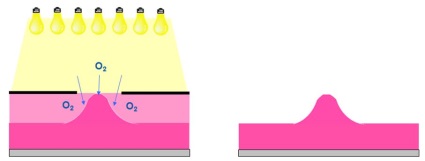

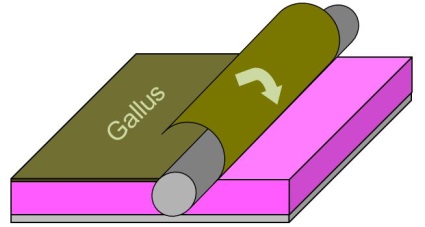

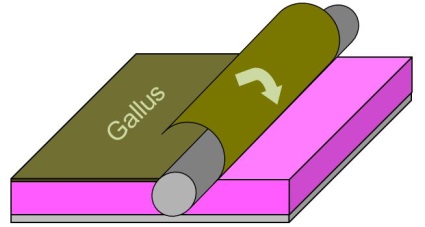

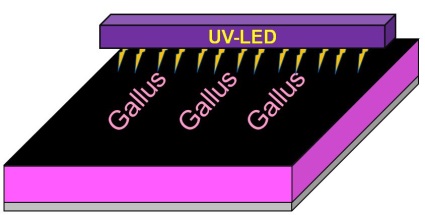

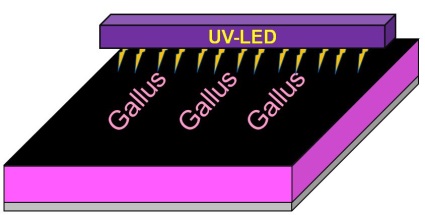

The "standard" digitally exposed photopolymer flexographic printing plate usually has a printing dot that is rounded at the tip. This is due to oxygen, which has a negative effect on the polymerization of the photopolymer during the UV exposure process, causing the screen dots to shrink.

Oxygen interferes with the polymerization of the photopolymer, causing print dots with rounded tips.

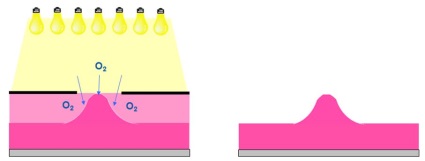

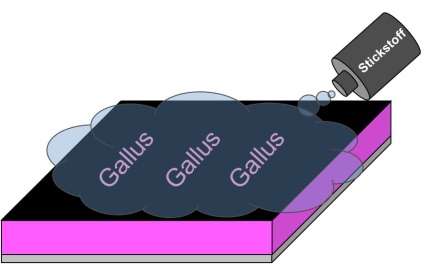

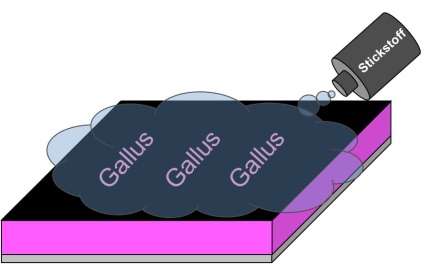

The shielding of oxygen enables ideal polymerization, resulting in flat pressure points.

The disruptive oxygen can be removed from the exposure process in various ways. Below are four methods used by printing plate manufacturers.

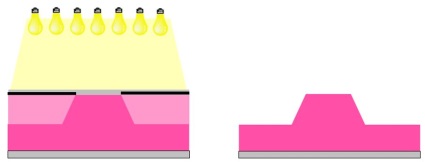

The laminated, laser-imaged film prevents direct contact with oxygen during the UV-A exposure process.

A membrane (thin film) is laminated onto the LAMS and prevents direct contact with oxygen during the UV-A exposure process.

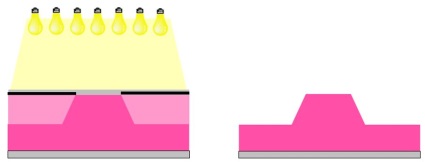

Pre-exposure with UV LEDs removes oxygen and simultaneously polymerizes the top layer of the plate.

During the normal UV-A exposure process, the plate is flooded with an inert gas (nitrogen), which displaces the oxygen.

Every printer has different requirements for a flexographic printing plate. While one may require very fast production times, another may be solely concerned with print quality. Still others place great importance on environmental considerations.

In principle, prepress and plate processing have a significant influence on the print result. However, the greatest influence is exerted by the plate material, which is a given and cannot be changed by the user.

During the print tests at Gallus's plants, flexographic printing plates from renowned manufacturers were printed, examined, and compared under identical conditions. Significant differences in the print results were observed.

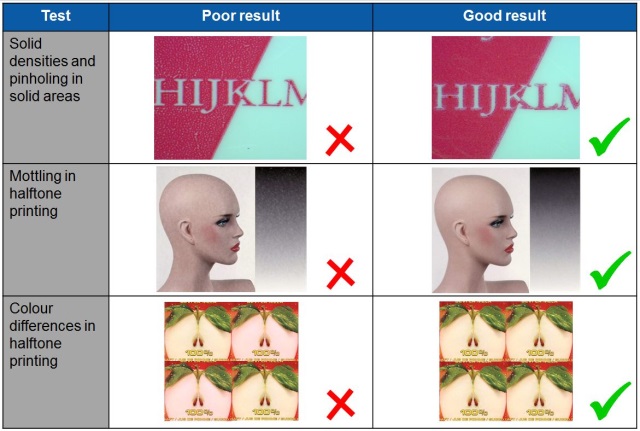

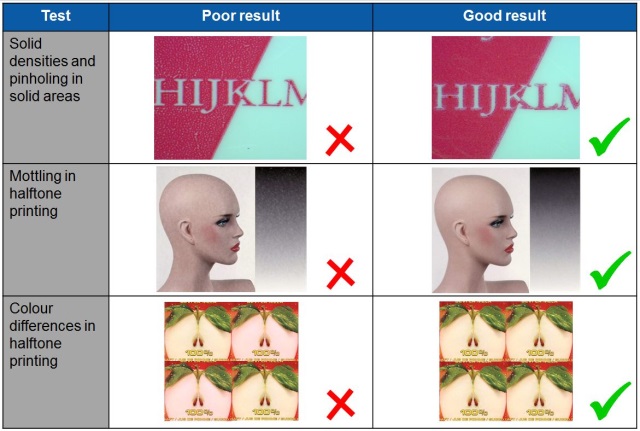

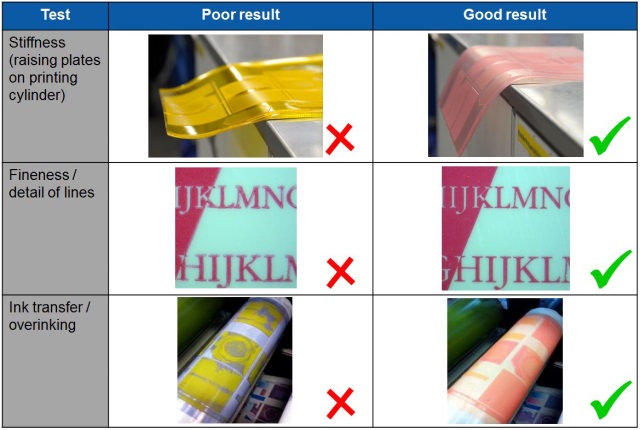

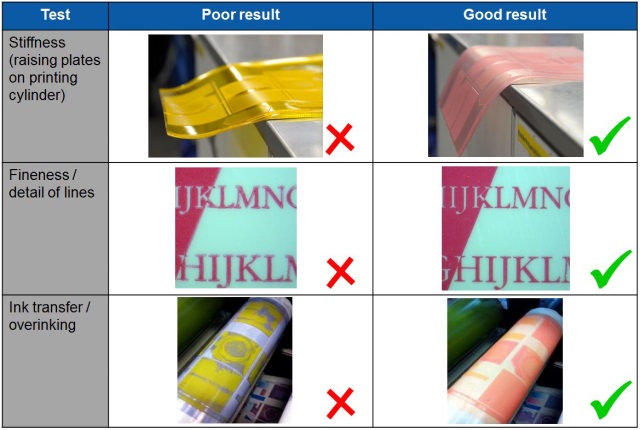

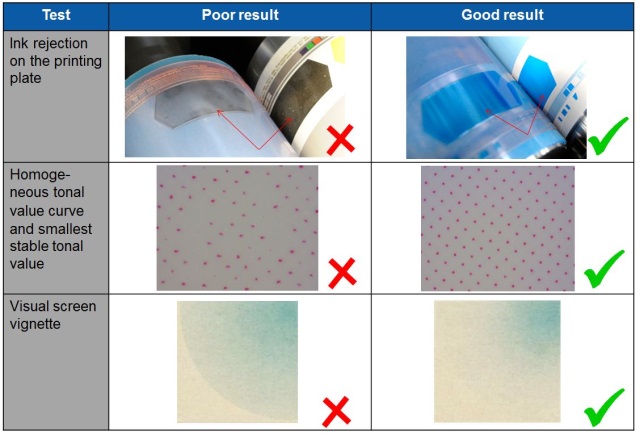

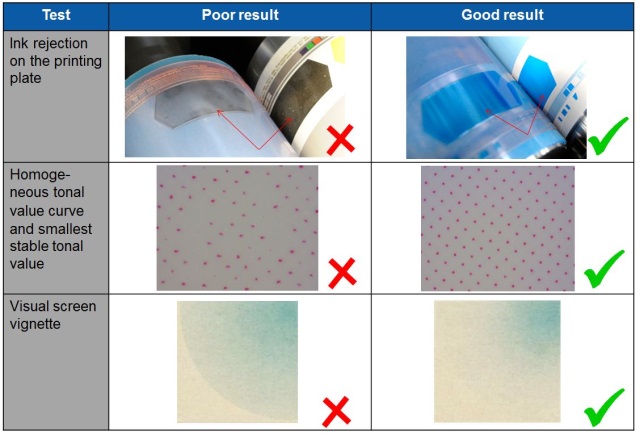

If you focus solely on print quality, there are several indicators that can help you decide whether a printing plate type is good or poor. Print shops looking for the best printing plate for their printing needs are advised to test and evaluate at least the following characteristics during print tests:

Table 1 of characteristics for pressure tests

Table 2 for pressure tests

Table 3 for pressure tests

The choice of flexographic printing plate type is extremely important for printers and has a decisive influence on print quality and production efficiency. When evaluating a printing plate, it is advisable to carry out comparative tests and examine the print results closely.

Through extensive printing tests, Gallus has gained a wealth of experience with the various types of flexographic printing plates. This knowledge and the insights gained are covered in detail and practiced in Gallus' printing technology seminars.

For further information on Gallus' printing technology seminars, please contact Roger Oberholzer (roger.oberholzer@gallus-group.com).

07.03.2016

The flexographic printing plate can be described as the heart of flexographic printing, as it has a decisive influence on the print results and production efficiency of a label printer. There are well over 40 different flexographic printing plates available on the market for label printers, but these can differ fundamentally in terms of their properties, printing behavior, and manufacturing process.

This often presents label printers with the extremely difficult task of selecting a suitable printing plate type. For this reason, Gallus took the time to thoroughly examine and compare the printing characteristics of all well-known flexographic printing plates during a test phase lasting several weeks. The results and evaluations ranged from excellent to unusable. Although there is no such thing as the perfect flexographic printing plate for all applications, a few top flexographic printing plates were identified that are ideal for label printers.

Most flexographic printing plates today are made of photopolymer; rubber plates are much less common. The washout processes for photopolymer printing plates range from the use of solvents to water and thermal development. However, the majority of photopolymer flexographic printing plates are washed out with solvents or water, with the individual steps (1-6) as follows:

In the printing plate market, there is currently a trend toward flat top dot technology. These printing plates have a printing point that is flat at the tip rather than rounded. This enables more consistent and accurate printing results.

The "standard" digitally exposed photopolymer flexographic printing plate usually has a printing dot that is rounded at the tip. This is due to oxygen, which has a negative effect on the polymerization of the photopolymer during the UV exposure process, causing the screen dots to shrink.

Oxygen interferes with the polymerization of the photopolymer, causing print dots with rounded tips.

The shielding of oxygen enables ideal polymerization, resulting in flat pressure points.

The disruptive oxygen can be removed from the exposure process in various ways. Below are four methods used by printing plate manufacturers.

The laminated, laser-imaged film prevents direct contact with oxygen during the UV-A exposure process.

A membrane (thin film) is laminated onto the LAMS and prevents direct contact with oxygen during the UV-A exposure process.

Pre-exposure with UV LEDs removes oxygen and simultaneously polymerizes the top layer of the plate.

During the normal UV-A exposure process, the plate is flooded with an inert gas (nitrogen), which displaces the oxygen.

Every printer has different requirements for a flexographic printing plate. While one may require very fast production times, another may be solely concerned with print quality. Still others place great importance on environmental considerations.

In principle, prepress and plate processing have a significant influence on the print result. However, the greatest influence is exerted by the plate material, which is a given and cannot be changed by the user.

During the print tests at Gallus's plants, flexographic printing plates from renowned manufacturers were printed, examined, and compared under identical conditions. Significant differences in the print results were observed.

If you focus solely on print quality, there are several indicators that can help you decide whether a printing plate type is good or poor. Print shops looking for the best printing plate for their printing needs are advised to test and evaluate at least the following characteristics during print tests:

Table 1 of characteristics for pressure tests

Table 2 for pressure tests

Table 3 for pressure tests

The choice of flexographic printing plate type is extremely important for printers and has a decisive influence on print quality and production efficiency. When evaluating a printing plate, it is advisable to carry out comparative tests and examine the print results closely.

Through extensive printing tests, Gallus has gained a wealth of experience with the various types of flexographic printing plates. This knowledge and the insights gained are covered in detail and practiced in Gallus' printing technology seminars.

For further information on Gallus' printing technology seminars, please contact Roger Oberholzer (roger.oberholzer@gallus-group.com).