03.03.2016

In our series "Practical experience in label printing," we address everyday challenges in label printing and how to solve them. In this issue, we focus on the topic: "Uneven ink coverage."

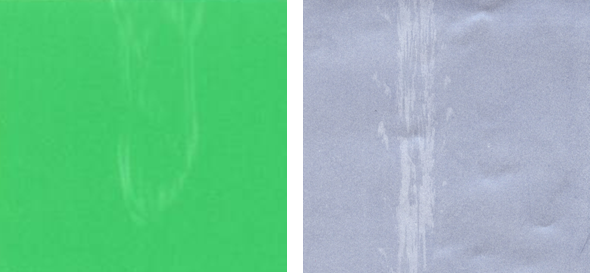

Problem identification:

Unevenly bright shadows and color dropouts appear in the print image, caused by air trapped in the anilox roll cells. The problem occurs more frequently with metallic colors and chamber blade flexographic printing units.

Troubleshooting:

03.03.2016

In our series "Practical experience in label printing," we address everyday challenges in label printing and how to solve them. In this issue, we focus on the topic: "Uneven ink coverage."

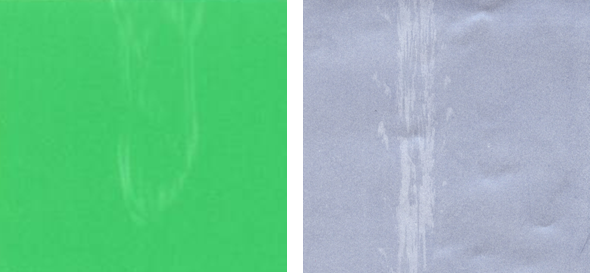

Problem identification:

Unevenly bright shadows and color dropouts appear in the print image, caused by air trapped in the anilox roll cells. The problem occurs more frequently with metallic colors and chamber blade flexographic printing units.

Troubleshooting: