03.03.2016

In order to maintain optimum print quality throughout the entire service life of an offset printing press, it is essential that the core components of the machine, the offset printing units, are properly maintained.

The introduction of offset printing in label printing machines heralded a new era. The advantages of offset printing, with fast and inexpensive plate changes and high resolution, have also been made available to label production.

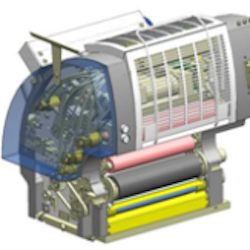

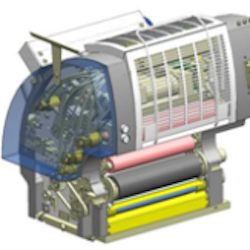

However, the offset printing process is much more complex than book or flexographic printing. This is easy to see by looking at the printing unit.

By their very nature, all mechanical parts are subject to wear and tear to a greater or lesser extent. To ensure optimum interaction between all components and thus the operational reliability of the entire system, Gallus recommends a three-step procedure to its customers.

1. Regular maintenance of the system in accordance with the machine documentation

2. Timely replacement of critical wear parts

3. Timely complete overhaul of the printing unit

Experience in the field clearly shows that in companies where the care and maintenance of printing machines is neglected due to high production pressures, machine productivity suffers over time. This manifests itself in more difficult operating points and corresponding time and waste costs, up to and including the total shutdown of production units. Productivity can only be maintained through proper cleaning and adherence to the maintenance cycles specified in the machine documentation.

Furthermore, production reliability is significantly increased by the timely replacement of critical wear parts. In offset printing, these are the distributor rollers and rubber rollers, which should be replaced at regular intervals depending on their degree of use. The reason: the diameter of the rollers changes over time due to abrasion. If the permissible tolerances are exceeded or not reached, this results in an uneven distribution of ink across the printing area, which impairs the print quality.

The procedure described above can significantly increase the service life of a printing unit. However, if maintenance and replacement of wear parts are no longer sufficient to ensure the highest print quality, this may indicate that the entire printing unit should undergo a Gallus factory overhaul. This involves replacing not only all rollers, but also all other mechanical parts that are subject to wear. A reconditioned printing unit is equivalent to a new system in terms of its properties and service life.

The support that Gallus offers its customers for the operational reliability of offset printing units is based on these three levels.

1. For care and maintenance, Gallus offers a range of options for gaining in-depth knowledge and skills in-house through its "Gallus Educate training packages." Of particular note is the three-day offset printing seminar, which explains the process in a clear and understandable way for Gallus machines. In addition, customer-specific training courses provide in-depth knowledge of the maintenance and servicing of the entire printing system.

2. Changing complete rollers is simplified by the fact that pre-assembled units equipped with gears and bearings can be obtained from Gallus. This means that the printing units can be returned to service with minimal time expenditure. In addition, a two-day offset printing unit seminar offers participants the opportunity to learn in detail about replacing wear parts and subsequent adjustment.

For customers who do not wish to acquire this knowledge themselves, there is of course always the option of having this work carried out by trained Gallus service technicians.

3. During a complete overhaul of offset printing units, Gallus completely dismantles the printing unit at its factory and replaces all mechanical wear parts. All settings on the printing unit are then readjusted.

During the overhaul period, either a loan printing unit can be obtained from Gallus or the exchange method can be selected. In this case, the customer retains the replacement printing unit supplied by Gallus and returns the printing unit sent for overhaul to Gallus.

Field experience clearly shows that the use of offset printing technology also requires new approaches to care and maintenance. Gallus supports its customers with a differentiated approach that can be tailored to the respective intensity of use and resources available to the customer.

03.03.2016

In order to maintain optimum print quality throughout the entire service life of an offset printing press, it is essential that the core components of the machine, the offset printing units, are properly maintained.

The introduction of offset printing in label printing machines heralded a new era. The advantages of offset printing, with fast and inexpensive plate changes and high resolution, have also been made available to label production.

However, the offset printing process is much more complex than book or flexographic printing. This is easy to see by looking at the printing unit.

By their very nature, all mechanical parts are subject to wear and tear to a greater or lesser extent. To ensure optimum interaction between all components and thus the operational reliability of the entire system, Gallus recommends a three-step procedure to its customers.

1. Regular maintenance of the system in accordance with the machine documentation

2. Timely replacement of critical wear parts

3. Timely complete overhaul of the printing unit

Experience in the field clearly shows that in companies where the care and maintenance of printing machines is neglected due to high production pressures, machine productivity suffers over time. This manifests itself in more difficult operating points and corresponding time and waste costs, up to and including the total shutdown of production units. Productivity can only be maintained through proper cleaning and adherence to the maintenance cycles specified in the machine documentation.

Furthermore, production reliability is significantly increased by the timely replacement of critical wear parts. In offset printing, these are the distributor rollers and rubber rollers, which should be replaced at regular intervals depending on their degree of use. The reason: the diameter of the rollers changes over time due to abrasion. If the permissible tolerances are exceeded or not reached, this results in an uneven distribution of ink across the printing area, which impairs the print quality.

The procedure described above can significantly increase the service life of a printing unit. However, if maintenance and replacement of wear parts are no longer sufficient to ensure the highest print quality, this may indicate that the entire printing unit should undergo a Gallus factory overhaul. This involves replacing not only all rollers, but also all other mechanical parts that are subject to wear. A reconditioned printing unit is equivalent to a new system in terms of its properties and service life.

The support that Gallus offers its customers for the operational reliability of offset printing units is based on these three levels.

1. For care and maintenance, Gallus offers a range of options for gaining in-depth knowledge and skills in-house through its "Gallus Educate training packages." Of particular note is the three-day offset printing seminar, which explains the process in a clear and understandable way for Gallus machines. In addition, customer-specific training courses provide in-depth knowledge of the maintenance and servicing of the entire printing system.

2. Changing complete rollers is simplified by the fact that pre-assembled units equipped with gears and bearings can be obtained from Gallus. This means that the printing units can be returned to service with minimal time expenditure. In addition, a two-day offset printing unit seminar offers participants the opportunity to learn in detail about replacing wear parts and subsequent adjustment.

For customers who do not wish to acquire this knowledge themselves, there is of course always the option of having this work carried out by trained Gallus service technicians.

3. During a complete overhaul of offset printing units, Gallus completely dismantles the printing unit at its factory and replaces all mechanical wear parts. All settings on the printing unit are then readjusted.

During the overhaul period, either a loan printing unit can be obtained from Gallus or the exchange method can be selected. In this case, the customer retains the replacement printing unit supplied by Gallus and returns the printing unit sent for overhaul to Gallus.

Field experience clearly shows that the use of offset printing technology also requires new approaches to care and maintenance. Gallus supports its customers with a differentiated approach that can be tailored to the respective intensity of use and resources available to the customer.