07.03.2016

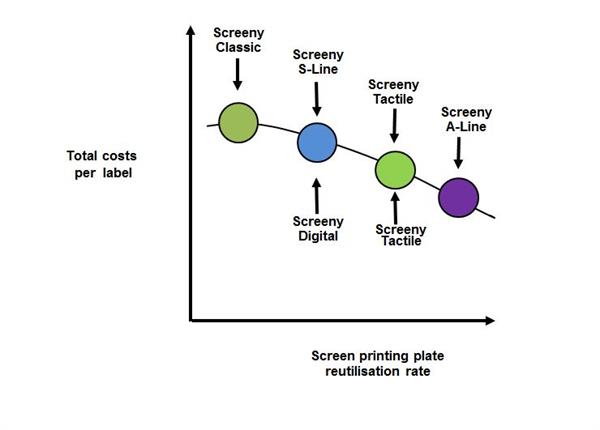

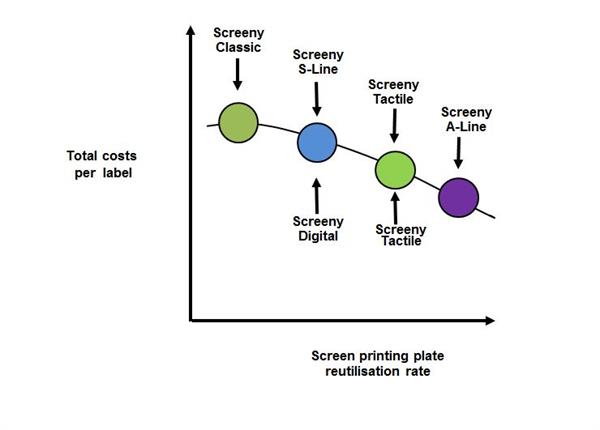

The Gallus Screeny A-Line is a screen printing plate that offers extreme robustness, excellent reusability, and maximum printing speeds. These properties contribute to a significant reduction in the cost per label when using Gallus Screeny A-Line.

Gallus Screeny A-Line has a unique flow-shape topography. This special flow-shape surface is the reason why the Gallus Screeny A-Line printing plate achieves perfect printing results even at the highest machine speeds. Higher machine speeds ultimately mean improved cost-effectiveness, as more jobs can be printed per unit of time.

Another feature that sets Gallus Screeny A-Line apart is its extreme robustness, which is particularly advantageous when handling screen printing plates both inside and outside the printing press. The exceptionally high stability of this printing plate prevents damage and thus simplifies handling in prepress and production. The Gallus Screeny A-Line is therefore designed for maximum reuse, because a higher reuse rate is the fastest way to significantly reduce the cost per screen print label. The more often the same screen printing plate is used for recurring jobs with the same print image, the lower the "total price" for this screen cylinder.

The Gallus Screeny A-Line not only offers outstanding advantages for recurring jobs with consistent print images, but also delivers outstanding benefits for long print jobs, as the Gallus Screeny A-Line can print more running meters of substrate per screen printing plate than conventional screen printing plates available on the market.

Advantages:

The Gallus Screeny A-Line is faster, stronger, and can be reused multiple times. This results in lower costs per label and thus improves the operator's profitability for label printing.

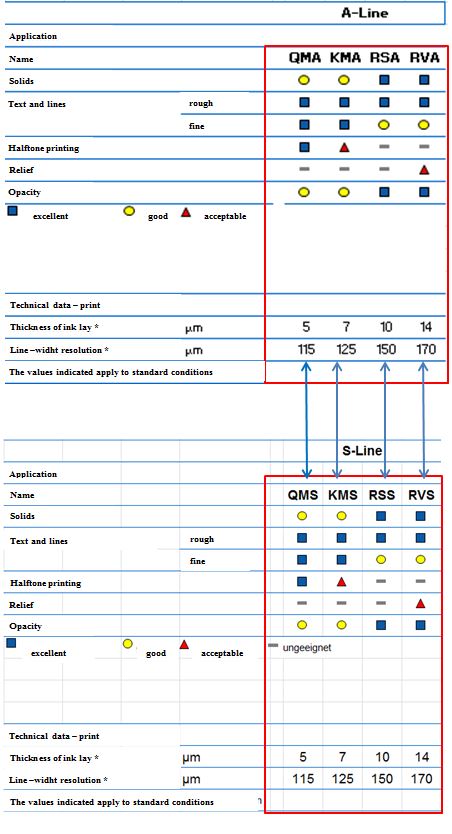

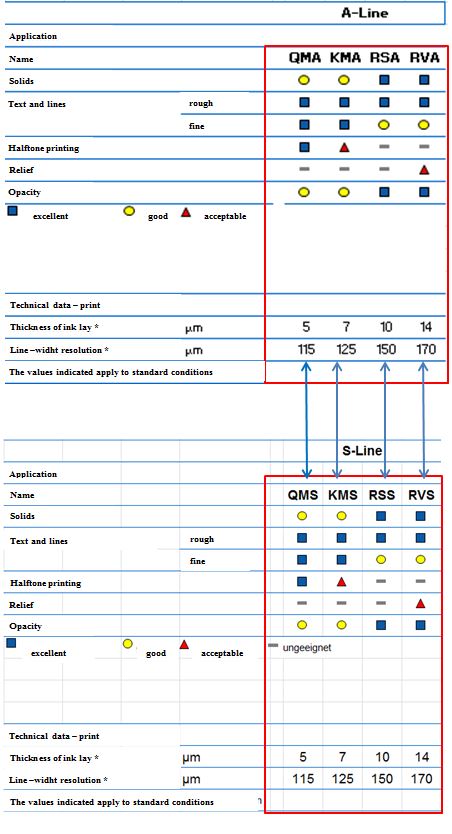

With consistent ink layer thickness and line resolution, the Gallus Screeny Advanced (A) line offers a screen printing plate that achieves first-class printing results and optimum image resolution, enabling a wide range of applications, perfect ink flow, high printing speeds and easy final inspection of the printed screen printing plates.

At Labelexpo 2015 in Brussels, two new Gallus Screeny A-Line models were presented to industry visitors: the Gallus Screeny KMA and RSA. The range has since been expanded to include the Gallus Screeny QMA and RVA models, offering extensive application options for all customers.

The Gallus Screeny A-Line is based on the minimum line width of the Gallus Screeny S-Line in terms of ink layer thickness and resolutions. This means that Gallus Screeny KMA achieves the same ink layer thickness and resolution of the minimum line width as Gallus Screeny KMS. This also applies to the other Gallus Screeny A-Line types.

Furthermore, technical details such as exposure factor, mesh count per inch, open mesh area in percent, and mesh size in micrometers remain equivalent to the S-Line. This means that the exposure times for the respective grades from the A-Line and S-Line, e.g., KMS and KMA, remain exactly the same. When changing grades, e.g. from the Gallus Screeny S-Line to the Gallus Screeny A-Line, the printing parameters and exposure time remain unchanged.

Lower your total cost per label withGallus Screeny A-Line!

07.03.2016

The Gallus Screeny A-Line is a screen printing plate that offers extreme robustness, excellent reusability, and maximum printing speeds. These properties contribute to a significant reduction in the cost per label when using Gallus Screeny A-Line.

Gallus Screeny A-Line has a unique flow-shape topography. This special flow-shape surface is the reason why the Gallus Screeny A-Line printing plate achieves perfect printing results even at the highest machine speeds. Higher machine speeds ultimately mean improved cost-effectiveness, as more jobs can be printed per unit of time.

Another feature that sets Gallus Screeny A-Line apart is its extreme robustness, which is particularly advantageous when handling screen printing plates both inside and outside the printing press. The exceptionally high stability of this printing plate prevents damage and thus simplifies handling in prepress and production. The Gallus Screeny A-Line is therefore designed for maximum reuse, because a higher reuse rate is the fastest way to significantly reduce the cost per screen print label. The more often the same screen printing plate is used for recurring jobs with the same print image, the lower the "total price" for this screen cylinder.

The Gallus Screeny A-Line not only offers outstanding advantages for recurring jobs with consistent print images, but also delivers outstanding benefits for long print jobs, as the Gallus Screeny A-Line can print more running meters of substrate per screen printing plate than conventional screen printing plates available on the market.

Advantages:

The Gallus Screeny A-Line is faster, stronger, and can be reused multiple times. This results in lower costs per label and thus improves the operator's profitability for label printing.

With consistent ink layer thickness and line resolution, the Gallus Screeny Advanced (A) line offers a screen printing plate that achieves first-class printing results and optimum image resolution, enabling a wide range of applications, perfect ink flow, high printing speeds and easy final inspection of the printed screen printing plates.

At Labelexpo 2015 in Brussels, two new Gallus Screeny A-Line models were presented to industry visitors: the Gallus Screeny KMA and RSA. The range has since been expanded to include the Gallus Screeny QMA and RVA models, offering extensive application options for all customers.

The Gallus Screeny A-Line is based on the minimum line width of the Gallus Screeny S-Line in terms of ink layer thickness and resolutions. This means that Gallus Screeny KMA achieves the same ink layer thickness and resolution of the minimum line width as Gallus Screeny KMS. This also applies to the other Gallus Screeny A-Line types.

Furthermore, technical details such as exposure factor, mesh count per inch, open mesh area in percent, and mesh size in micrometers remain equivalent to the S-Line. This means that the exposure times for the respective grades from the A-Line and S-Line, e.g., KMS and KMA, remain exactly the same. When changing grades, e.g. from the Gallus Screeny S-Line to the Gallus Screeny A-Line, the printing parameters and exposure time remain unchanged.

Lower your total cost per label withGallus Screeny A-Line!