The series entitled “Labelprinting – experience gained in practice” looks at everyday challenges encountered in labelprinting and how to overcome them. In this issue we take a look at “Colour irregularities”.

Definition of problem:

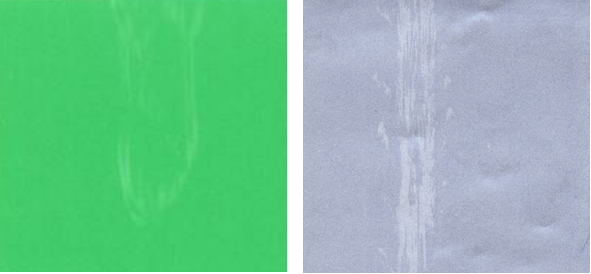

Uneven shadows and colour irregularities in the printed image, caused by air bubbles in the anilox roller cells. The problem occurs more frequently when working with metallic inks and flexographic printing units with chambered doctor blades.

Possible solutions:

- Reduce the ink viscosity

- Reduce the ink level in the ink chamber

- Increase the ink flow in the ink duct by continuous pumping

(= create circuit in ink duct)

- Reduce the press speed

- Change the ink series

- Use Gallus anti-stencilling insert for ink chambers

- Gallus EM280: Diameter of fountain roller is too small (should be 60.9 mm). If the diameter is less than 60.0 mm, the fountain roller must be replaced.