The Asia Brewery decoration team.

The Asia Brewery Inc glass plant reports increased productivity in screen preparation and production following its operation of the Gallus C-Line system for direct ACL printing on containers. According to Matthias Rosenfelder, the extended life of screens reduces the number of stops on decoration lines, while use of the Screeny printing plate has raised the level of image sharpness and brilliance, leading to additional business.

Gallus invented Screeny printing plate technology 30 years ago. The industrial manufacturing process of reinforcing and presensitising of plates has revolutionised screen printing. Screeny printing plates have been used in rotary screen printing applications and have proven their benefits in highly demanding ps label printing.

Numerous other applications such as solar cell, precision and holloware printing have underlined the benefits of the product and led to a wide range of satisfied customers throughout the world.

Recently, Gallus developed the quick-action Screeny C-Line system. This allows the use of Screeny plate technology for the ACL process in the glass decorating industry. The smart frame system guarantees a fast and precise plate loading process.

Within six minutes, a screen is prepared and ready to print. Proven Screeny screen plate technology allows the easy and fast manufacture of screens. The standardised prepress process of Gallus Screeny C-Line delivers a time saving of 60 minutes when compared to conventional screen manufacture.

Founded in 1982, Asia Brewery Inc is a major player in the Philippines beverage and industrial packaging industry. ABI offers a wide variety of popular alcoholic as well non-alcoholic beverages. The company continues to launch new products and uplift beverage standards. It aims “to be first in offering Filipinos nothing less than the best”. Therefore, improving the quality of the labels printed on their bottles is one consequential step to achieving this ambitious goal.

Screeny C-Line screen plates raise appearance by sharper image and superior brilliance, as illustrated by this Cobra beer bottle.

The trials revealed the great potential of the Gallus Screeny printing plates when used in the ACL process. These convincing factors led to the decision by ABI to switch to the Gallus Screeny C-Line system.

Gallus REM picture mesh and emulsion.

Gallus REM picture mesh and emulsion.

Enhanced productivity in ACL decoration is assured, increasing the lifespan of screens up to 18 hours (100,000 printed bottles). Reduced labour is required in prepress, involving a preparation time of six minutes per screen and employing a system approach for the reduction of human errors. In addition, the Gallus Screeny C-Line system delivers astonishing detail resolution and excellent colour appearance

The Gallus Screeny C-Line – four easy steps to ready-to-print-screen within six minutes:

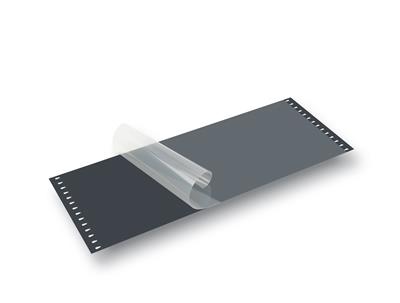

Step 1: Peel off protective film from presensitised Screeny plate.

Step 1: Peel off protective film from presensitised Screeny plate.

Step 2: Expose Screeny plate with film or with CtS-UV.

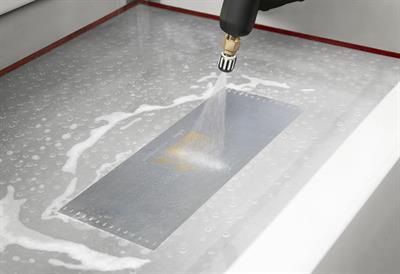

Step 3: Wash out of image by tap water and dry screen plate.

Step 4: Fixing of imaged screen in quick-action heating frame.